Volvo CE : Adblue and FAP troubleshooting

Discover our 3 methods

EnginesVolvo CE

Our process for eliminating emission defects on Volvo CE vehicles

Total deactivation by factory programming

Anti-pollution elements are deactivated via the vehicle's OBD connector. We downgrade your vehicle to an earlier version for countries not subject to the current standard. (e.g. Africa, Middle East...).

Each anti-pollution component can be disconnected from the machine (DPFS, AdBlue tank, sensors, EGR valve, etc.).

The ACM can be permanently disconnected. Ideal if it's faulty.

Recommended average intervention time: 2h

Total deactivation with custom reprogramming

The deactivation of emission control elements is done by hard programming in the engine management system (EMS) and in the ACM separately. We retain your current software version and program the new data directly into the ECU's flash memory.

AdBlue pump, FAP differential pressure sensor and AdBlue injector can be disconnected.

The ACM must remain connected.

Recommended average intervention time: 3h

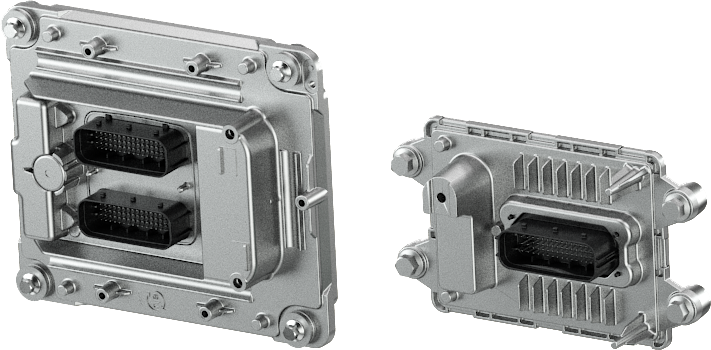

FAP and AdBlue deactivation via virtualization box

Deactivation concerns the FAP and AdBlue systems. The EGR system (managed by the EMS) is not concerned here. Installation of the box is straightforward. Its connector is identical to the one on your machine.

Elements connected to the DPF and SCR system can be disconnected.

The ACM (gas post-treatment unit) is replaced by our system virtualization module.

Recommended average intervention time: 15min to assemble yourself. Disconnect your ACM and connect our box.

Adblue removal on Volvo CE excavators

We specialize in troubleshooting and programming AdBlue systems on Volvo CE excavators. This intervention allows the definitive removal of fault codes on your Volvo CE excavator. The main models are EC and ECR.

Non-exhaustive list. Not all models are listed.

Adblue removal on Volvo CE loaders

We specialize in troubleshooting and programming AdBlue systems on Volvo CE loaders. This intervention allows the definitive removal of fault codes on your Volvo CE loader. The main models are

Non-exhaustive list. Not all models are listed.

Adblue removal on Pipelayer Volvo CE

We specialize in troubleshooting and programming AdBlue systems on Volvo CE excavators. This intervention allows fault codes to be permanently removed from your Volvo CE pipelayer. The main models are

Adblue removal on Volvo CE demolition machine

We specialize in troubleshooting and programming AdBlue systems on Volvo CE loaders. This intervention allows the definitive removal of fault codes on your Volvo CE demolition machine. The main models are

Other Volvo CE machines available for AdBlue suppression

Various other types of Volvo CE machines fitted with AdBlue and FAP modules may also encounter faults. These include graders, waste compactors, drills, road pavers, tunnel-building vehicles and mining vehicles.