Défaut Adblue sur Hydrema MX16 – Diagnostic, suppression et optimisation moteur Cummins

Les engins de chantier comme l’Hydrema MX16, équipés du moteur Cummins QSB 4.5, rencontrent fréquemment des dysfonctionnements liés au système AdBlue. Ces défauts peuvent provoquer des arrêts machine, des pertes de puissance et une baisse significative de productivité. Grâce à une intervention par reprogrammation via le logiciel Calterm, il est possible de désactiver totalement ce dispositif et de restaurer un fonctionnement optimal.

En modifiant les paramètres du calculateur CM2350, nous mettons en place une configuration plus stable, sans impact sur la mécanique, tout en supprimant les codes défauts persistants. Le résultat : un moteur plus fiable, sans voyants, et des performances rétablies sur chantier.

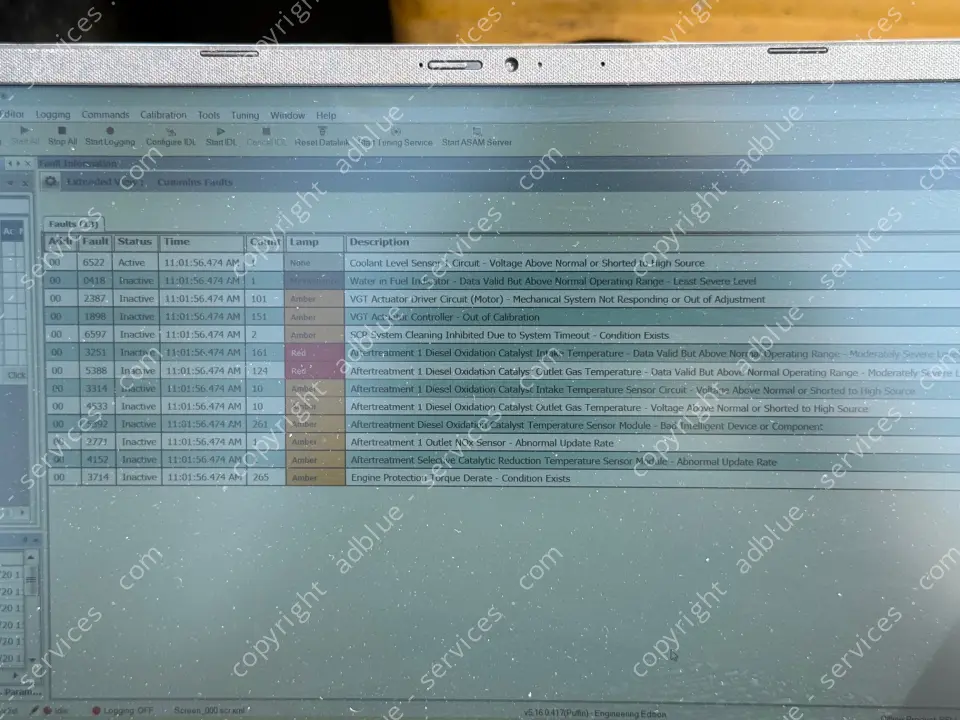

Analyse des défauts liés au système antipollution Hydrema MX16

Un diagnostic électronique avancé est indispensable avant toute intervention. Malgré le remplacement de plusieurs éléments, de nombreux utilisateurs constatent des défauts récurrents impossibles à corriger durablement sans suppression complète du système.

- 6597 : Nettoyage SCR (AdBlue) interrompu suite à un dépassement de délai. Souvent lié à un catalyseur inactif ou un mauvais pilotage de l’ACM.

- 3251 / 3258 : Température d’entrée ou de sortie du catalyseur au-dessus de la norme – peut entraîner une dégradation du DOC.

- 3314 / 4533 : Tension excessive ou court-circuit vers source haute sur les capteurs de température. Mauvaise lecture entraînant des calculs erronés.

- 5392 : Module intelligent défectueux – empêche le traitement correct des températures critiques SCR.

- 2771 / 4152 : Taux de mise à jour anormal des capteurs NOx ou température SCR. Défaut de communication entre les modules.

- 3714 : Passage en mode dégradé avec limitation du couple moteur. Résultat direct d’un défaut post-traitement non résolu.

Suppression du système SCR et désactivation des défauts moteur sur Hydrema MX16

Notre solution consiste à neutraliser électroniquement les fonctions liées à l’AdBlue et aux capteurs SCR via une intervention dans le calculateur moteur CM2350. Cette opération s’effectue sans démontage et garantit un fonctionnement stable, sans perte de couple ni passage en mode dégradé.

Étapes de l’intervention

- Diagnostic complet : Identification des défauts via outils spécialisés, vérification des modules ACM et ECU.

- Lecture ECU : Extraction du fichier moteur binaire (.bin) via protocole sécurisé sur CM2350.

- Analyse : Étude des blocs AdBlue, DPF, EGR. Identification des fonctions à désactiver.

- Suppression : Désactivation des fonctions SCR, neutralisation des erreurs, arrêt de l’injection d’urée.

- Recalcul des checksums : Vérification de la cohérence et intégrité du fichier pour éviter tout défaut ultérieur.

- Réécriture et tests : Réinjection du fichier dans l’ECU et validation complète sur le terrain.

Désactivation EGR et stabilisation thermique moteur

La vanne EGR, en réinjectant les gaz d’échappement, favorise l’encrassement moteur. Sa suppression empêche les dépôts, réduit les montées en température internes, et élimine les modes dégradés causés par les blocages ou dysfonctionnements EGR fréquents sur ce type de motorisation.

Amélioration de la fiabilité moteur après intervention

Suite à cette opération :

-

✅ Les codes défauts liés au système SCR ont été supprimés durablement, y compris les erreurs récurrentes (6597, 3714, etc.).

-

✅ Le mode dégradé a été levé, rétablissant l’intégralité du couple moteur et une réponse franche à l’accélération.

-

✅ Les redémarrages à froid sont plus fluides, sans activation du système de chauffe ni tentative de régénération.

-

✅ Les messages d’entretien AdBlue ont disparu, évitant les immobilisations inutiles.

-

✅ La consommation d’urée est stoppée sans impacter la combustion ni les performances.

-

✅ La disponibilité machine est immédiate : plus de blocage, plus d’arrêt chantier pour défaut de post-traitement.

-

✅ Le moteur fonctionne désormais de manière stable, sans voyant moteur ni notification au tableau de bord.

En supprimant les limitations imposées par les systèmes AdBlue, DPF et EGR, le moteur retrouve une meilleure stabilité, une réponse franche, et une absence totale de codes défauts. L’engin est immédiatement disponible, sans voyant au tableau de bord ni arrêt inopiné.

Vous intervenez sur plusieurs modèles Hydrema ? Découvrez nos autres solutions sur la page Hydrema. Vous travaillez également avec d’autres moteurs Cummins ? Consultez notre section dédiée : moteurs Cummins.