Défaut antipollution sur Sany SY500 – Comment résoudre définitivement ?

Introduction

Le Sany SY500, équipé du moteur Cummins QSG12, subit fréquemment des pannes liées au système SCR. Un défaut antipollution sur Sany SY500 peut provoquer une perte de puissance, des arrêts non prévus et des coûts d’entretien élevés. Pour éviter ces problèmes, on supprime les dispositifs comme l’AdBlue ou le DPF, souvent responsables de ces défaillances. En reprogrammant le calculateur CM2350, on désactive ces fonctions sans affecter les performances du moteur. Résultat : la machine tourne sans défaut, sans bridage, et sans entretien inutile.

Diagnostic des défauts pour Défaut antipollution sur Sany SY500 (ECU CM2350)

Un diagnostic complet et précis est essentiel avant toute intervention sur le système antipollution d’un engin tel que le Sany SY500 équipé du moteur CM2350. En effet, il n’est pas rare que certaines erreurs récurrentes persistent malgré le remplacement de plusieurs composants. Cette situation conduit souvent les opérateurs à envisager la suppression définitive du système défaillant pour éviter des interruptions coûteuses et répétées.

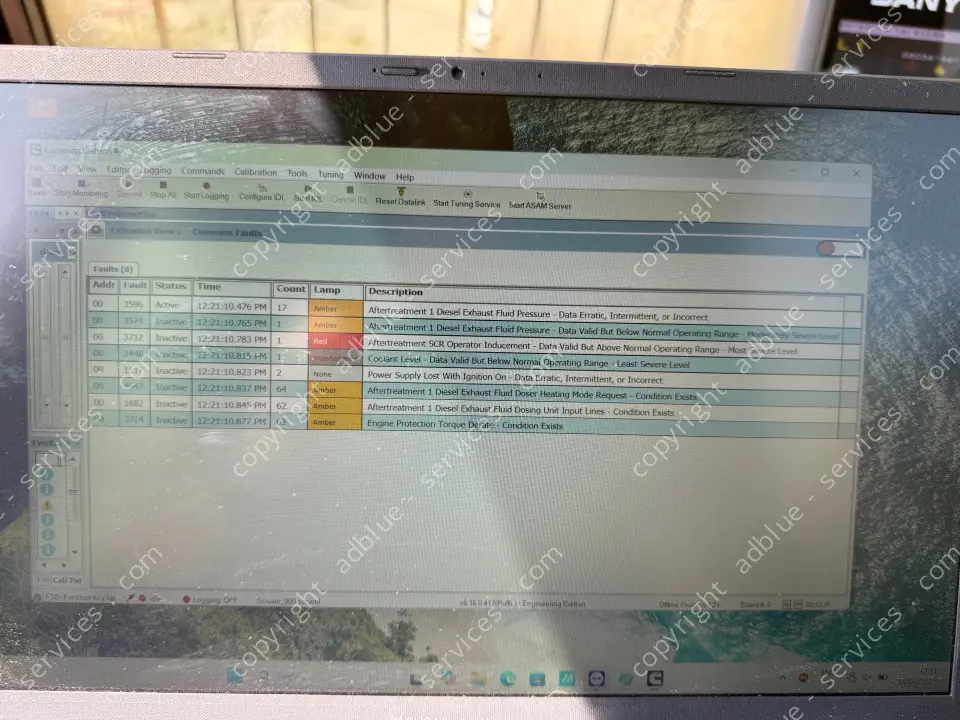

Lors de notre intervention sur ce modèle, plusieurs défauts ont été relevés, chacun nécessitant une attention particulière pour comprendre leur origine et leurs implications :

Code 3596 – Aftertreatment 1 Diesel Exhaust Fluid Pressure – Data Erratic, Intermittent, or Incorrect

Traduction : Pression du fluide AdBlue – Données erratiques, intermittentes ou incorrectes

Code 3596 ACTIF PRÉSENT 17 FOIS

Ce code signale un problème de cohérence dans la lecture de la pression du liquide de dépollution (DEF / AdBlue). Le calculateur moteur reçoit une donnée erratique, intermittente ou incorrecte, ce qui suggère un dysfonctionnement du capteur de pression ou un défaut dans le circuit (colmatage, fuite, doseur encrassé). La probabilité de panne est élevée. Ce type de défaut peut désactiver le système SCR (réduction catalytique sélective), entraînant rapidement une stratégie de limitation moteur avec perte progressive de puissance.

Code 3574 – Aftertreatment 1 Diesel Exhaust Fluid Pressure – Data Valid But Below Normal Operating Range – Moderately Severe Level

Traduction : Pression du fluide AdBlue – Données valides mais en dessous de la plage normale (niveau modérément sévère)

Code 3574 INACTIF ACTUELLEMENT MAIS REVIENT AU BOUT DE 30MIN

Ce défaut indique que la pression du fluide DEF est bien détectée mais qu’elle se situe en dehors de la plage normale de fonctionnement, à un niveau trop bas. Cela peut être dû à un débit insuffisant, un encrassement partiel, ou un doseur défectueux. Bien que le signal reste techniquement valide, ce type d’anomalie est surveillé de près par le système, et peut, s’il persiste, déclencher une stratégie d’inducement. La probabilité de panne est modérée, mais les conséquences peuvent rapidement devenir critiques si aucun correctif n’est apporté.

Code 3712 – Aftertreatment SCR Operator Inducement – Data Valid But Above Normal Operating Range – Most Severe Level

Traduction : Inducement SCR – Données valides mais au-dessus de la plage normale autorisée (niveau le plus sévère)

Code 3712 INACTIF ACTUELLEMENT MAIS REVIENT AU BOUT DE 30MIN

Ce code correspond à un seuil critique dans la gestion du système SCR. Il confirme l’activation d’une stratégie d’inducement moteur, déclenchée suite à un dépassement des tolérances admissibles concernant le traitement des gaz d’échappement. En pratique, cela se traduit par une réduction immédiate de la puissance disponible afin de forcer une intervention. Ce défaut est grave. Il est souvent consécutif à d’autres codes non traités (pression DEF, capteurs SCR, doseur), et peut aller jusqu’à bloquer les redémarrages si ignoré.

Défauts ci-dessous récurrents, apparus plus de 60 fois et qui reviennent au bout de 15 à 30min :

Code 4947 – Aftertreatment 1 Diesel Exhaust Fluid Doser Heating Mode Request – Condition Exists

Traduction : Demande d’activation du mode de chauffage du doseur AdBlue – Condition active

Code 4947 INACTIF ACTUELLEMENT MAIS REVIENT AU BOUT DE 30MIN

Ce code indique que le système a demandé l’activation du mode de chauffage du doseur AdBlue. Cette fonction est essentielle en conditions de température basse, pour éviter le gel ou la cristallisation du fluide. Si le chauffage ne s’active pas correctement, l’injection DEF est suspendue, ce qui désactive le traitement SCR. Ce défaut, souvent lié à un capteur thermique ou une résistance défectueuse, a une probabilité d’apparition modérée, mais peut entraîner une stratégie d’inducement sévère si la situation persiste.

Code 1682 – Aftertreatment 1 Diesel Exhaust Fluid Dosing Unit Input Lines – Condition Exists

Traduction : Lignes d’entrée du module doseur AdBlue – Condition active

Code 1682 INACTIF ACTUELLEMENT MAIS REVIENT AU BOUT DE 30MIN

Ce défaut concerne les lignes d’entrée du doseur DEF, incluant les capteurs de température, de pression et de débit intégrés. Lorsqu’un dysfonctionnement est détecté sur ces signaux, le calculateur considère le système comme non fiable, ce qui entraîne la coupure immédiate de l’injection d’AdBlue. Il s’agit d’un défaut courant, avec une probabilité de panne élevée, notamment en cas de doseur défectueux ou de connectique abîmée. Ce code est un déclencheur direct d’inducement moteur avec réduction du couple et de la puissance.

Code 3714 – Engine Protection Torque Derate – Condition Exists

Traduction : Réduction de couple moteur par stratégie de protection – Condition active

Code 3714 INACTIF ACTUELLEMENT MAIS REVIENT AU BOUT DE 30MIN

Ce code indique que le moteur a subi une réduction de couple appliquée par stratégie de protection. Il ne représente pas un défaut isolé, mais une conséquence directe d’un ou plusieurs défauts liés au système antipollution. Ce bridage est mis en place par l’ECU pour protéger le moteur ou forcer une réparation. Même si le code est actuellement inactif, il atteste qu’une période de limitation moteur a bien eu lieu récemment, ce qui peut justifier des pertes de performance observées par l’utilisateur.

Étapes de reprogrammation après un défaut antipollution sur Sany SY500 Suppression définitive

Lorsqu’un défaut antipollution survient sur une Sany SY500, la machine entre souvent en mode dégradé avec perte de puissance et messages d’erreur au tableau de bord. Pour retrouver un fonctionnement normal sans remplacement coûteux de composants, une reprogrammation ciblée du calculateur moteur permet de corriger durablement le problème. Voici, étape par étape, comment cela se passe concrètement.

Étape 1 : Diagnostic et lecture du calculateur

Dans un premier temps, on procède à un diagnostic complet du système moteur. À l’aide d’un outil spécialisé, les erreurs présentes sont identifiées, puis les données du calculateur sont récupérées. Cela permet d’extraire un fichier contenant toute la configuration actuelle du moteur. Cette étape est indispensable, car elle permet d’intervenir de manière précise et ciblée.

Étape 2 : Analyse du fichier et préparation de la modification

Une fois le fichier récupéré, on l’analyse en détail afin de repérer les zones liées aux systèmes SCR, DPF ou EGR. L’objectif est simple : désactiver uniquement ce qui pose problème, sans toucher aux fonctions essentielles du moteur. Ainsi, la modification reste propre, efficace, et totalement réversible si besoin.

Étape 3 : Suppression des restrictions et stratégies de bridage

À ce stade, on neutralise les éléments responsables des limitations de puissance. De plus, on supprime les stratégies automatiques qui réduisent le couple moteur dès qu’un défaut antipollution est détecté. Grâce à ces ajustements, le moteur retrouve un fonctionnement fluide et constant, sans perte de performance sur la Sany SY500.

Étape 4 : Vérification du fichier modifié

Avant toute réécriture, il est impératif de vérifier la cohérence complète du fichier. En effet, cette vérification garantit que toutes les données sont stables, sans erreur, et que le calculateur acceptera la nouvelle configuration sans risque. Par conséquent, cette étape assure la fiabilité de l’intervention.

Étape 5 : Réécriture et validation terrain et élimination définitive du défaut antipollution sur Sany SY500

Une fois le fichier validé, il est réinjecté dans le calculateur via l’outil de programmation. Ensuite, la machine est testée en conditions réelles. On s’assure du bon démarrage, de l’absence totale de défauts, et du retour complet des performances moteur. C’est pourquoi cette reprogrammation permet de supprimer définitivement le défaut antipollution sur Sany SY500, sans avoir à remplacer de pièce.

En savoir plus sur Sany et les désactivations d’émission

Vous travaillez sur d’autres modèles de la marque Sany ? Découvrez toutes nos solutions de suppression AdBlue, DPF et EGR dans la section dédiée à la gamme Sany.

Vous êtes également amené à intervenir sur différents moteurs Cummins ? Consultez notre page dédiée aux moteurs Cummins pour en savoir plus sur nos interventions compatibles.