Défaut SCR sur Sennebogen 830 : Plus de puissance

Le système de réduction catalytique sélective (SCR) est un composant essentiel des engins modernes tels que le Sennebogen 830, équipé d’un moteur Cummins. Cependant, des défauts SCR peuvent survenir, entraînant des dysfonctionnements qui perturbent l’efficacité opérationnelle de la machine. Ces problèmes se manifestent souvent par une entrée en mode dégradé, réduisant considérablement les performances et augmentant le risque d’interruptions coûteuses.

Pour remédier à ces désagréments et éviter les pannes répétitives, la suppression définitive des systèmes AdBlue, FAP et EGR s’avère être une solution efficace. Cette intervention permet non seulement de sortir du mode dégradé mais aussi d’assurer une continuité dans l’utilisation de l’engin sans interruptions intempestives.

Sur le plan technique, la reprogrammation du calculateur CM2350 joue un rôle crucial. En modifiant les données internes du calculateur, il est possible d’implémenter de nouveaux paramètres qui optimisent le comportement du moteur Cummins QSB4.5. Cette approche garantit une performance accrue tout en éliminant les contraintes liées aux systèmes antipollution défaillants.

Dépollution défaillante : diagnostic avancé sur Sennebogen 830

Réaliser un diagnostic complet et précis est crucial avant toute intervention sur un système antipollution comme le SCR (Selective Catalytic Reduction) du Sennebogen 830. En effet, de nombreux utilisateurs constatent que certaines erreurs récurrentes persistent malgré le remplacement de plusieurs composants. Ce phénomène conduit souvent à envisager la suppression définitive du système en cause pour éviter les interruptions fréquentes et coûteuses.

Lors de notre intervention sur ce modèle équipé du système CM2350, plusieurs défauts ont été relevés. Voici une analyse technique des codes d’erreur identifiés, accompagnée d’une interprétation des causes probables et des conséquences potentielles :

Code défauts présents en relation avec le système d’émissions

- Code 4863: Aftertreatment SCR Operator Inducement Active – Condition Exists

Traduction : SCR – Inducement actif (mesure incitative) : condition présente.

Interprétation : Ce code indique que le système a activé une mesure incitative pour encourager l’opérateur à résoudre un problème lié au traitement des gaz d’échappement. Les causes possibles incluent une défaillance dans l’injection d’AdBlue ou un dysfonctionnement du catalyseur SCR. Les conséquences peuvent être une réduction de la performance moteur ou une augmentation des émissions polluantes. - Code 3714: Engine Protection Torque Derate – Condition Exists

Traduction : Protection moteur – Réduction de couple active : condition présente.

Interprétation : Ce défaut signale que le moteur a réduit son couple pour se protéger contre des conditions potentiellement dommageables. Cela peut résulter d’un problème dans le circuit AdBlue ou d’une température excessive dans le système d’échappement. La conséquence directe est une perte de puissance qui peut affecter l’efficacité opérationnelle. - Code 5867: Aftertreatment Diesel Exhaust Fluid Dosing Unit Relay Feedback – Voltage Below Normal

Traduction : Post-traitement – Retour relais unité de dosage AdBlue : tension trop basse.

Interprétation : Une tension inférieure à la normale au niveau du relais de l’unité de dosage AdBlue suggère un problème électrique, tel qu’un câblage défectueux ou un relais endommagé. Cela peut entraîner une incapacité à doser correctement l’AdBlue, compromettant ainsi l’efficacité du traitement SCR. - Code 3558: Aftertreatment 1 Diesel Exhaust Fluid Dosing Unit – Voltage Above Normal

Traduction : Post-traitement – Unité de dosage AdBlue n°1 : tension trop élevée.

Interprétation : Une tension supérieure à la normale indique possiblement un court-circuit ou une surcharge électrique dans l’unité de dosage AdBlue n°1. Les conséquences incluent potentiellement une surconsommation d’AdBlue et un fonctionnement erratique du système antipollution.

L’analyse précise de ces codes permet non seulement d’identifier les composants problématiques mais aussi de décider si la suppression complète du système AdBlue est justifiée pour garantir la fiabilité opérationnelle continue de votre équipement Sennebogen 818E.

🔧 Diagnostic et suppression du défaut SCR sur Sennebogen 830

Intervention suite à un défaut SCR sur Sennebogen 830

Nous avons été sollicités pour intervenir sur une Sennebogen 830 équipée du moteur Cummins QSB4.5. La machine présentait un défaut SCR entraînant une réduction automatique du couple moteur. Ce défaut SCR sur Sennebogen 830 perturbait le bon fonctionnement de l’engin et limitait ses performances.

Sans intervention, l’engin restait en mode dégradé, rendant son exploitation impossible. Il était donc essentiel de supprimer le système AdBlue devenu défaillant. L’objectif : éliminer les défauts actifs et restaurer la pleine puissance moteur.

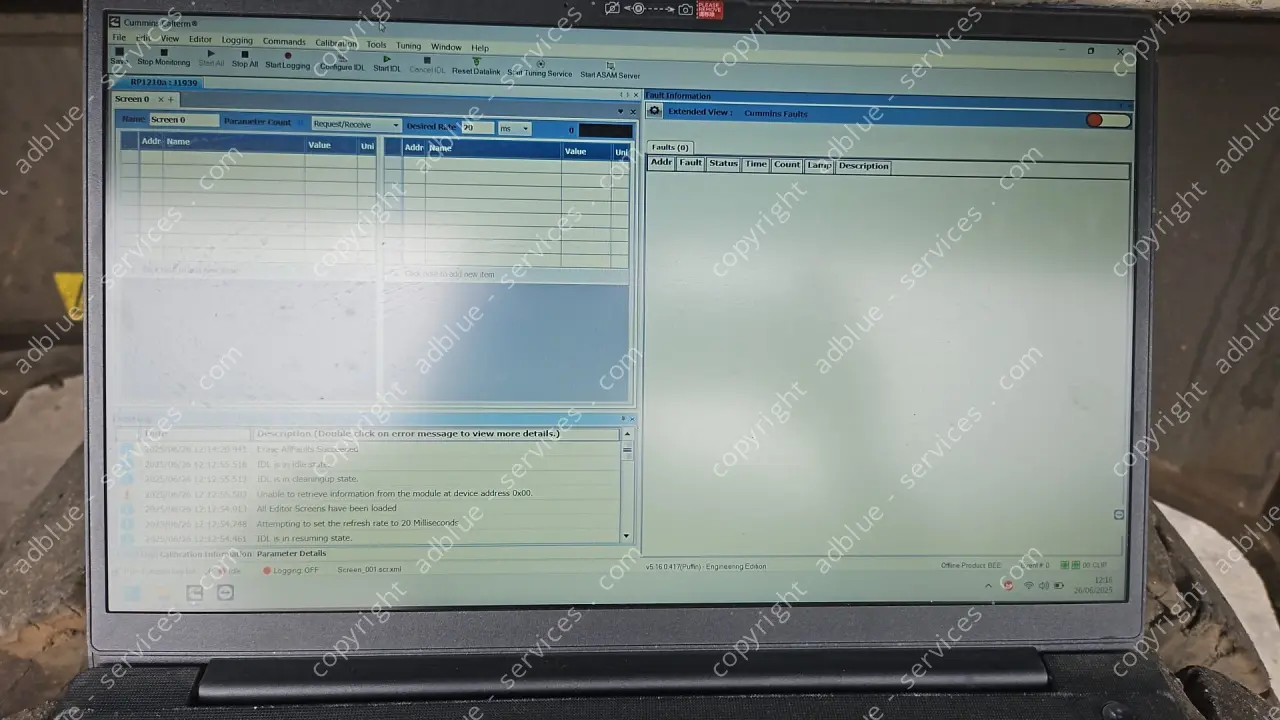

À l’aide d’un outil de diagnostic électronique, nous avons accédé aux données internes du calculateur CM2350. Plusieurs erreurs étaient actives. Parmi elles, une tension incorrecte sur l’unité de dosage AdBlue et l’inducement SCR déclenché. Ces éléments confirmaient un défaut SCR sur la Sennebogen 830 nécessitant une intervention logicielle ciblée.

Suppression du défaut SCR et restauration des performances

Après extraction des données de l’ECU au format binaire, nous avons analysé en détail les paramètres liés à la dépollution. L’objectif n’était pas seulement d’effacer les erreurs visibles. Il fallait corriger les déclencheurs internes du système pour éviter toute récidive.

Les ajustements ont concerné la désactivation de l’injection AdBlue, la suppression des limitations de couple et, si nécessaire, l’émulation du filtre à particules. Un recalcul complet des checksums a ensuite été effectué pour assurer une parfaite cohérence avec le calculateur CM2350.

Une fois le fichier corrigé injecté dans l’ECU, des essais terrain ont été réalisés. Le moteur a redémarré sans aucune alerte. Aucun message d’erreur n’est réapparu. Le défaut SCR sur la Sennebogen 830 a été totalement supprimé. La machine a retrouvé toute sa puissance, sans risque d’interruption lié au système de post-traitement.

Nos autres interventions sur Cummins et Sennebogen

Vous intervenez sur plusieurs modèles Sennebogen ? Découvrez nos autres solutions sur la page Sennebogen. Vous travaillez également avec d’autres moteurs Cummins ? Consultez notre section dédiée : moteurs Cummins.