Pour résoudre ces soucis, nous proposons de supprimer définitivement l’Adblue, le FAP et l’EGR. Cette intervention élimine tous les défauts et voyants au tableau de bord. Vous n’aurez plus besoin d’ajouter de l’adblue, garantissant un fonctionnement sans voyant ni alerte.

En modifiant les données du calculateur CM2350, nous intégrons de nouveaux paramètres pour le moteur Komatsu SAA6D (Moteur Cummins QSB 6.7). Cela permet une adaptation précise aux nouvelles conditions opérationnelles, améliorant ainsi la fiabilité globale du véhicule.

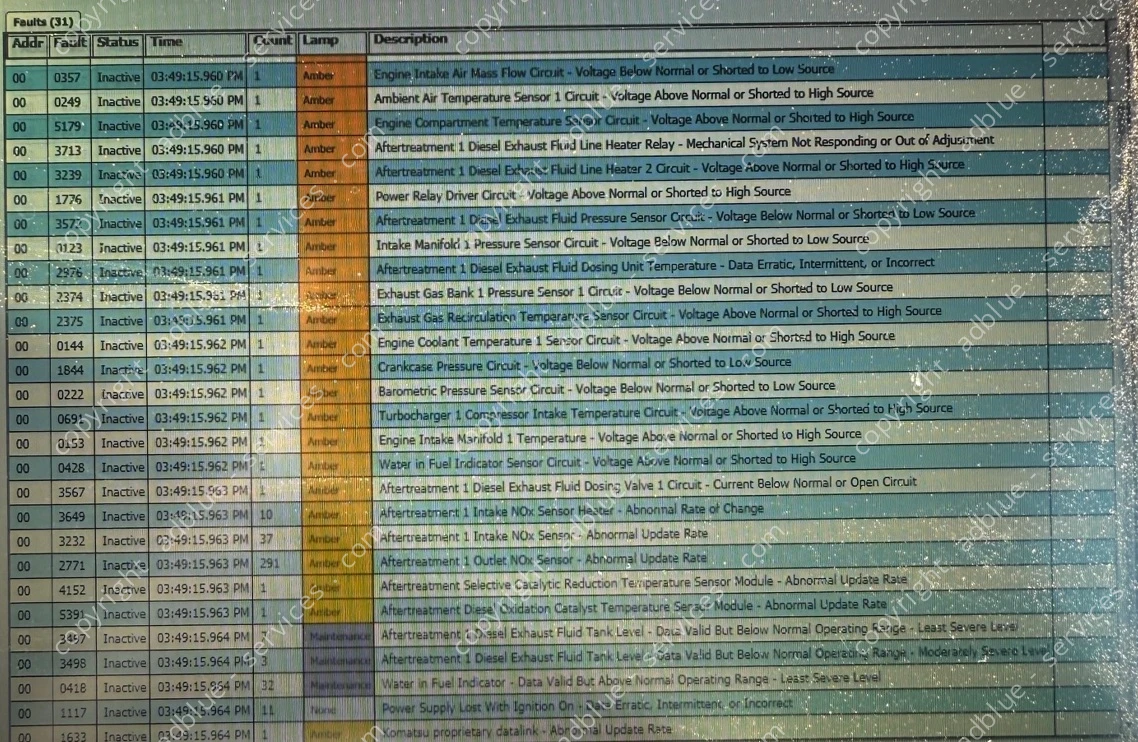

Défauts Courants de l’ECU CM2350 rencontrés sur les machines

| Code | Description FR | Évaluation technique |

|---|---|---|

| 0373 | Chauffage de ligne DEF – Relais inopérant ou hors tolérance | Forte probabilité de défaillance du relais de commande ou d’un élément de la ligne de chauffage DEF. Possibilité de résistance ouverte ou relais mécaniquement bloqué. |

| 3713 | Chauffage ligne DEF n°2 – Tension excessive | Le défaut suggère un court-circuit vers la source de tension ou une alimentation anormale du circuit. Vérification du câblage et de l’intégrité du capteur indispensable. |

| 0375 | Capteur de pression DEF – Tension trop basse | Probabilité élevée de rupture de ligne, court-circuit à la masse ou capteur interne défectueux. Vérification au multimètre recommandée. |

| 0376 | Capteur de pression DEF – Tension trop élevée | Défaut souvent causé par un court-circuit vers la source positive. Vérification de la continuité du circuit et de la polarité nécessaire. |

| 0378 | Température unité de dosage DEF – Valeur incohérente | Possibilité de capteur thermique interne défectueux, signal hors plage attendue. Analyse croisée avec température ambiante et mesures physiques recommandée. |

| 0380 | Unité de dosage DEF – Données erratiques | Défaut lié à des données de capteur instables ou bruitées, pouvant indiquer une défaillance matérielle de l’unité ou un problème de communication CAN. |

| 0381 | Capteur de niveau DEF n°1 – Tension trop basse | Indique généralement une perte de signal due à un câblage endommagé ou un capteur défaillant. Vérification de la résistance du circuit à effectuer. |

| 0382 | Capteur de niveau DEF n°1 – Tension trop élevée | Défaut typique d’un court-circuit vers le +Vbat ou d’un capteur hors spécifications. Surveillance de la ligne de signal recommandée. |

| 0384 | Niveau DEF – Donnée valide mais inférieure à la plage normale | Défaut souvent représentatif d’un niveau réel bas. Si le réservoir est plein, suspecter une erreur de lecture du capteur. |

| 0385 | Niveau DEF bas – Alerte de niveau 1 | Niveau de fluide proche de la limite basse. Surveillance du comportement du capteur si l’alerte persiste après remplissage. |

| 0387 | Niveau DEF bas – Alerte critique (niveau 2) | Fortement probable que le réservoir soit vide ou que le capteur soit défaillant. Blocage moteur possible selon les stratégies SCR. |

| 0388 | Capteur de température DEF – Fréquence de mise à jour irrégulière | Défaut de communication possible entre le capteur et l’ECU. Le problème peut être matériel ou lié au bus CAN. |

| 0389 | Capteur de qualité DEF – Fréquence de mise à jour irrégulière | Défaut typique d’un capteur vieillissant ou déconnecté. Vérification de la ligne CAN, alimentation, et intégrité du module recommandé. |

| 0390 | Capteur de température SCR – Fréquence de mise à jour irrégulière | Peut indiquer une défaillance de capteur ou un délai de communication excessif. Vérifier l’intégrité du faisceau et du capteur. |

| 0391 | Capteur température SCR n°1 – Fréquence de mise à jour irrégulière | Même analyse que 0390. Surveillance du trafic CAN et test du capteur à l’oscilloscope peuvent être utiles. |

| 0392 | Capteur de qualité DEF n°1 – Fréquence de mise à jour irrégulière | Défaut similaire au 0389. Peut résulter d’une perte d’alimentation intermittente, d’une masse flottante ou d’une dérive logicielle. |

Ces défauts peuvent entraîner des dysfonctionnements majeurs si non traités rapidement. En supprimant les dispositifs antipollution, on peut améliorer la fiabilité globale du système en éliminant ces sources potentielles d’erreurs. En conclusion, un diagnostic précis associé à une reprogrammation moteur adéquate peut offrir une solution durable aux problèmes récurrents liés aux systèmes antipollution.

Panne AdBlue sur Bull Komatsu : Processus de Reprogrammation et Suppression AdBlue sur Komatsu PXi

En cas de panne AdBlue sur un Bull Komatsu, la reprogrammation moteur représente une solution technique fiable et durable. Notre intervention suit un protocole rigoureux, spécifiquement adapté aux machines équipées des systèmes CM2350

📍 Étapes du processus :

-

Diagnostic électronique complet

Nous commençons par une analyse approfondie des défauts liés aux systèmes antipollution. Cela inclut l’identification des erreurs actives sur les calculateurs CM2350 et ACM, ainsi que les anomalies dans les communications CANBUS. -

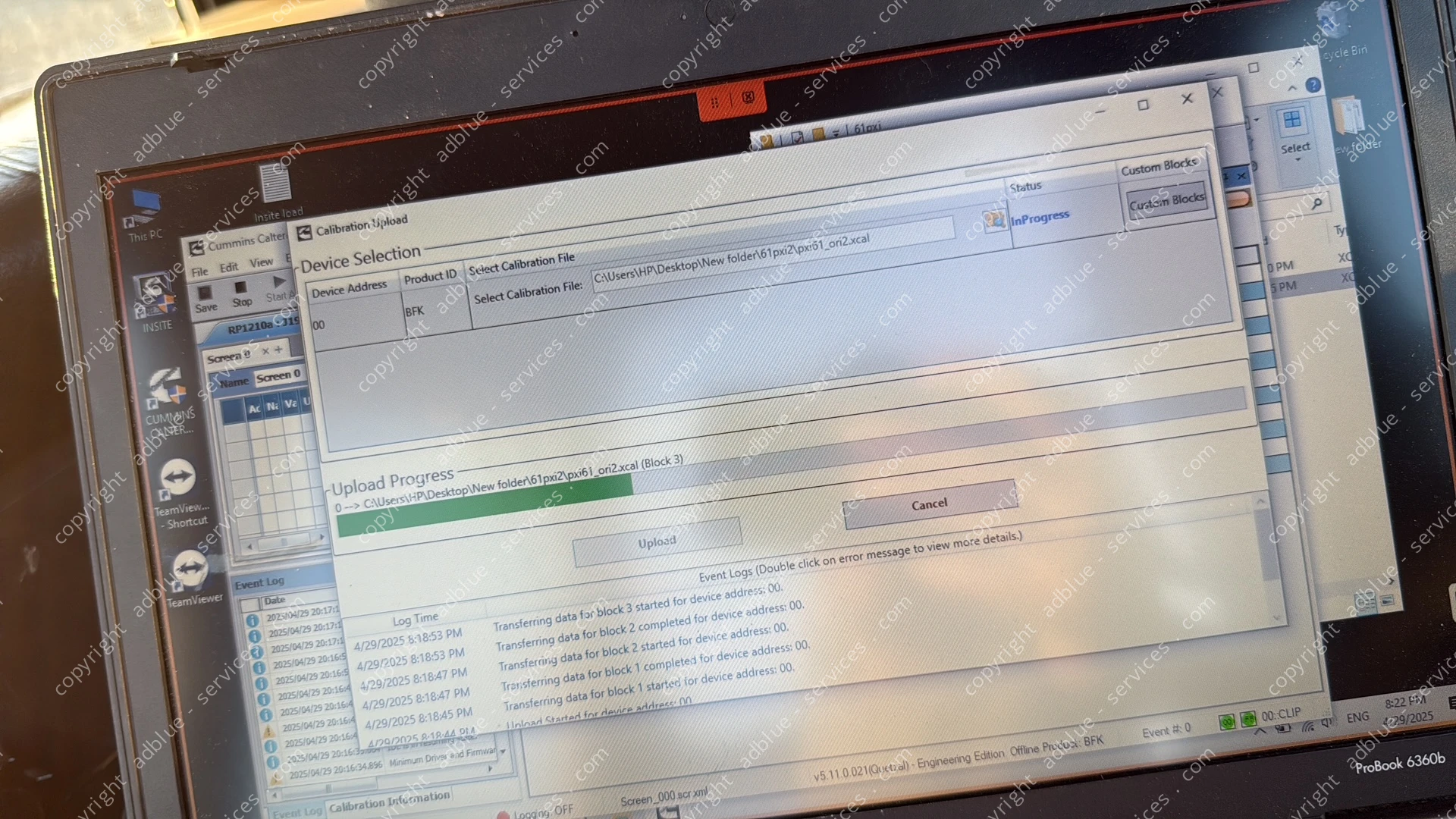

Lecture et sauvegarde de l’ECU CM2350

La configuration du calculateur est lue via une extraction flash, garantissant une copie précise de la mémoire interne sous format.xcal.

-

Modification des données binaires

Les valeurs de fonctionnement sont ajustées afin de :-

Supprimer les codes d’erreur liés à l’AdBlue et au DPF (codes en dur)

-

Neutraliser les remontées d’alertes récurrentes

-

Émuler le fonctionnement du filtre à particules et du taux de suie

-

Désactiver l’injection d’AdBlue en toute sécurité

-

-

Écriture du fichier modifié

Une fois les nouvelles données validées, l’écriture dans l’ECU est réalisée avec recalcul des checksums pour assurer l’intégrité logicielle. -

Ajustements supplémentaires

Si nécessaire, certains modules (notamment le module DEF ou les extensions SCR) sont désactivés pour garantir une compatibilité parfaite avec la nouvelle configuration.

Découvrez nos autres interventions sur Komatsu

Vous rencontrez une panne AdBlue ou un dysfonctionnement du système antipollution sur une machine Komatsu ? Consultez notre page dédiée à toutes nos interventions sur les machines Komatsu pour en savoir plus sur les solutions que nous proposons : suppression AdBlue, DPF, EGR, neutralisation des capteurs NOx et rétablissement des performances.

Par ailleurs, si votre engin est motorisé en Cummins (QSB, QSL, ISB…), que ce soit sur un Komatsu ou une autre marque (Liebherr, Case, Terex, etc.), vous pouvez également consulter notre page dédiée aux moteurs Cummins.

Vous êtes un professionnel de la reprogrammation moteur ?

Nous proposons aussi nos solutions en File Services prêtes à l’emploi ! Rendez-vous sur notre plateforme File Services pour les professionnels pour commander directement vos suppressions AdBlue, DPF, EGR et bien plus encore, avec un traitement rapide et précis.