Défaut Cat M313D : Jauge, Niveau Adblue et Communication

Défauts persistants sur le système AdBlue CAT M313D

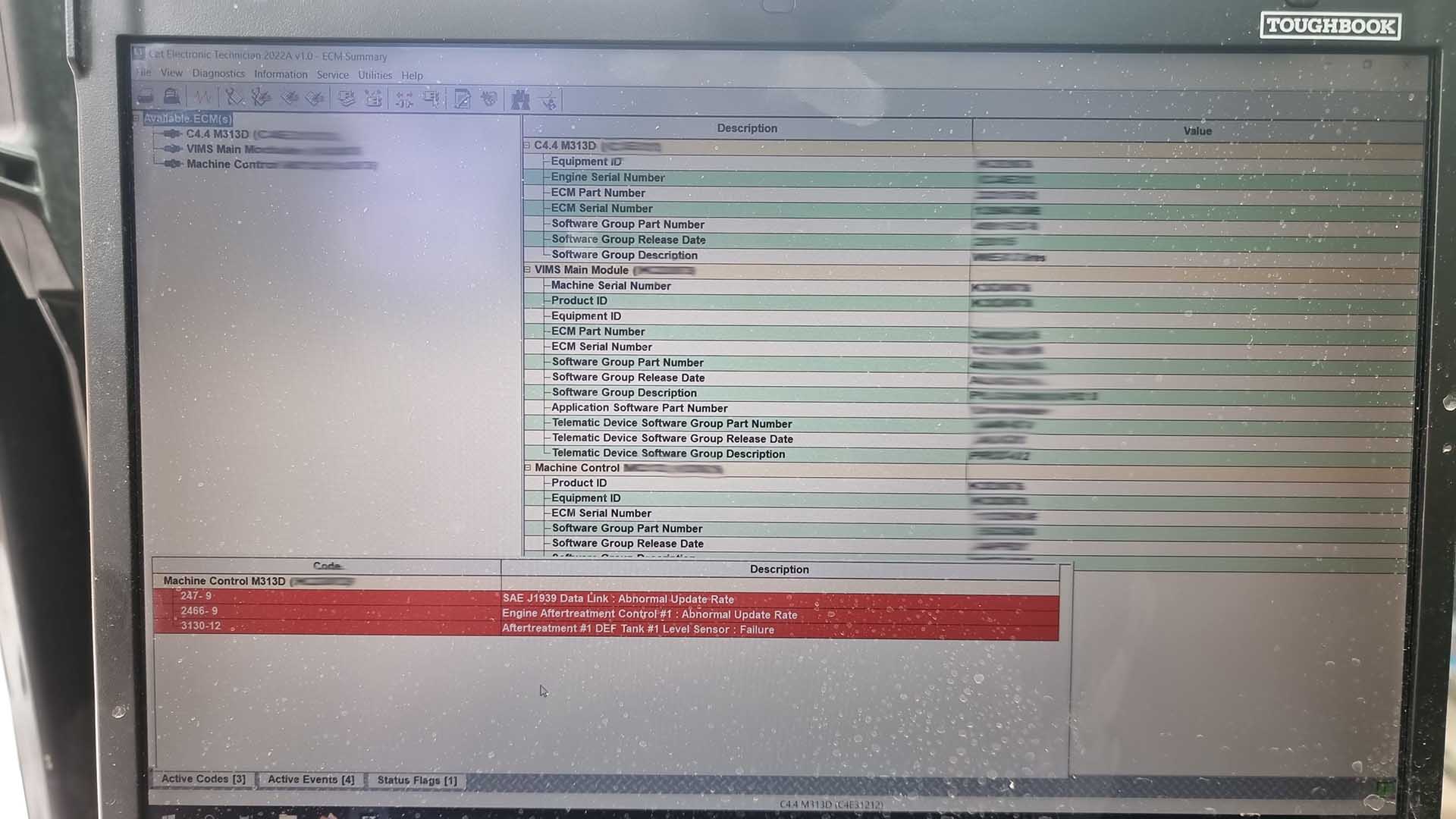

Suite à un problème récurrent sur une pelle sur roues M313D, nous avons été amené à supprimer définitivement le système SCR. En effet, les données de contrôles post traitement sont perturbées. Le signal ne parvient pas correctement jusqu’au module de contrôle moteur ADEM V. Deux défauts principaux sont présents sur cette pelle : le défaut 2466-9 et le 3130-12.

Le défaut 2466-9 indique qu’il y a un problème avec le système de gestion de l’après-traitement du moteur de la pelle sur roues M313D Caterpillar. « Abnormal update rate » signifie que le taux de mise à jour des données du système est anormal ou erroné. Cela peut être causé par un certain nombre de facteurs, tels qu’un problème avec les capteurs du système, un logiciel défectueux ou des problèmes de communication.

Le défaut 3130-12 informe qu’il y a un problème avec le capteur de niveau de réservoir de réducteur de NOx (DEF) de post traitement des gaz du moteur de la pelle sur roues M313D Caterpillar. DEF est l’acronyme de « Diesel Exhaust Fluid », c’est l’adblue. Son but est de réduire les émissions de NOx. Le capteur de niveau de réservoir de DEF mesure le niveau de fluide dans le réservoir de DEF et envoie des informations au système de gestion de l’après-traitement. Si ce capteur ne fonctionne pas correctement, il peut entraîner des problèmes de performance ou de fiabilité du système de gestion des émissions.

Le réservoir complet ainsi que la jauge ont été changés par le propriétaire mais le défaut persiste. La solution ultime est donc de supprimer définitivement le système de post traitement (et de revendre la machine).

Suppression SCR sur pelle M313D

La pelle étant en mode dégradé, il était totalement impossible de travailler avec. En effet le limp mode bloque les performances moteur à 100% sur cette pelle, celle-ci ne pouvait même plus être déplacée.

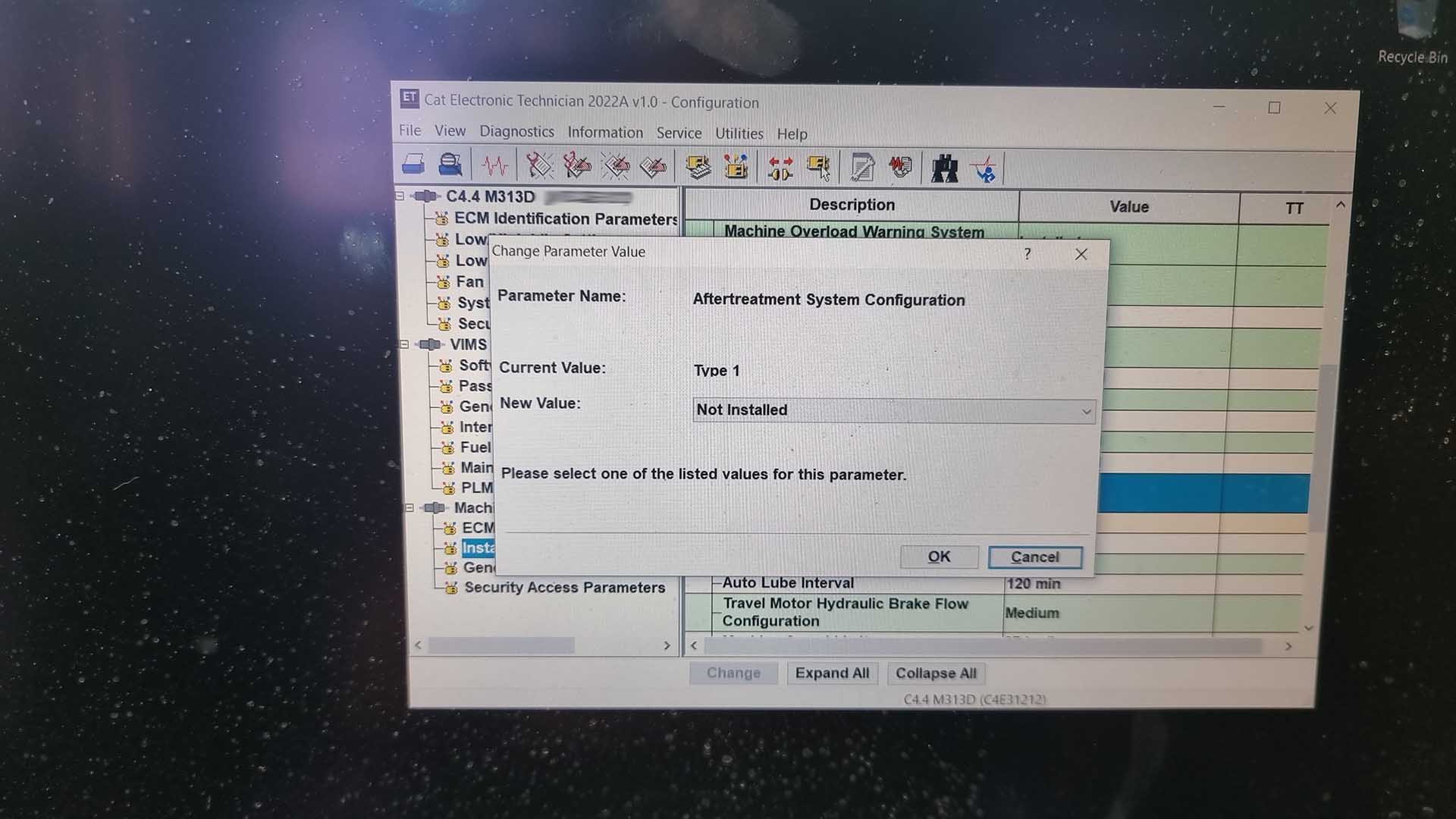

La suppression totale et définitive du système de post traitement se fait par le biais de logiciels spécifiques permettant de flasher un nouveau programme moteur développé par notre équipe d’ingénieurs. Ce programme définit que l’injection de DEF sera nulle, efface définitivement les codes défauts du tableau de bord, évite la consommation d’adblue. De plus il saute les limites de restriction de performances moteur liées aux émissions. Théoriquement il ne devrait être possible de réaliser cette opération que si la pelle était revendue à l’étranger car elle ne correspondrait plus aux normes antipollution. Il en va de la responsabilité du client final d’en faire ce qu’il souhaite.

Nous avions également le défaut 247-9 (SAE J1939 Abnormal rate update). Ce défaut 247-9 est lié aux autres défauts mentionnés, car le système de communication SAE J1939 peut être utilisé pour transmettre des données entre différents systèmes de la machine, tels que le système de gestion du moteur et le calculateur de post-traitement des gaz. Une fois notre nouveau programme flashé nous pouvons débrancher le calculateur de post traitement sans pour autant avoir de défauts. Le problème est donc résolu. Nous configurons le module non présent via nos outils.

Opérations possibles sur toute la gamme Caterpillar

Notre savoir faire permet d’intervenir sur la totalité des machines Cat, tous moteurs et calculateurs confondus. Vous pouvez retrouver le récapitulatif et la faisabilité des machines CAT sur notre page explicative ainsi que toutes nos opérations déjà réalisées ici.