Problème de régénération sur Volvo L180H : Solution complète

Introduction

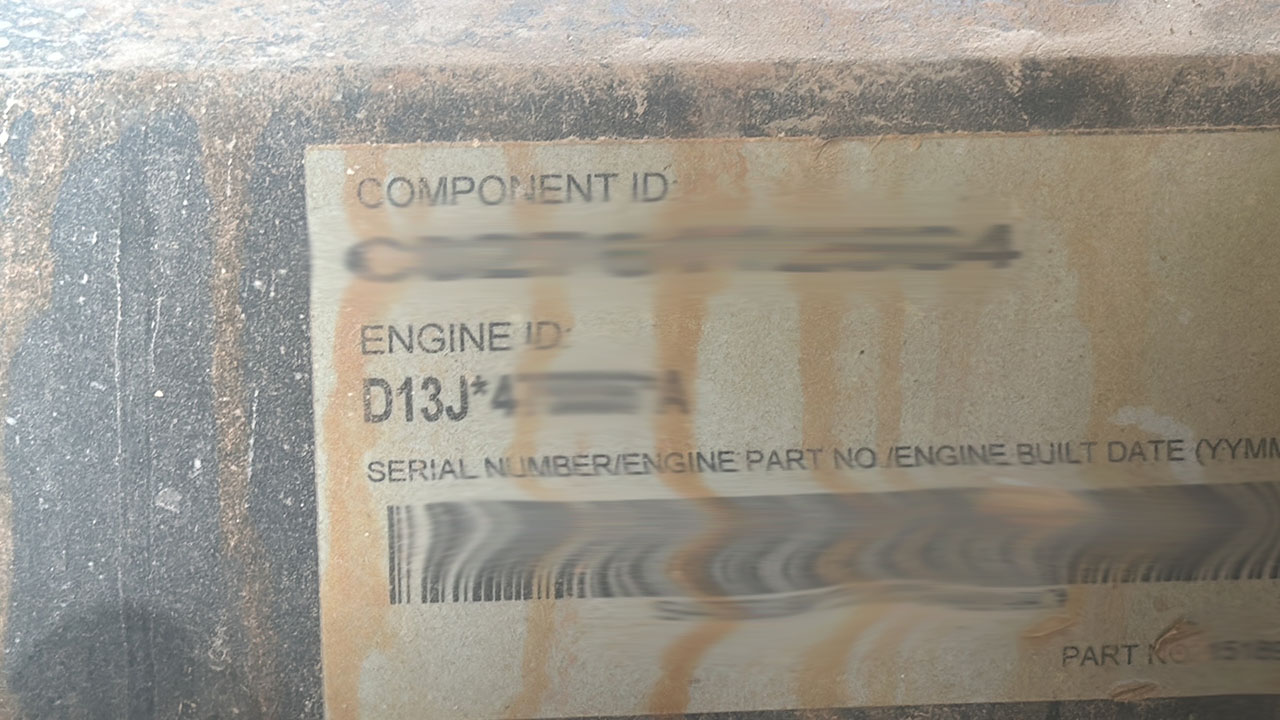

Le problème de régénération sur Volvo L180H est un défi courant pour de nombreux opérateurs. Ce type de machine, équipé du moteur D13J, souffre fréquemment de régénération impossible, panne système, perte de puissance, et FAP colmaté. Ces défauts entraînent souvent un passage en mode dégradé, réduisant considérablement l’efficacité et la performance de la machine.

Diagnostic initial

Lors de notre intervention sur la chargeuse L180H Volvo, nous avons constaté que la solution de régénération envisagée par le client était inefficace. Le taux de suie était trop élevé, rendant la régénération impossible. En outre, le système AdBlue était défaillant, les capteurs NOx fonctionnant par intermittence, ajoutant une couche supplémentaire de complexité au problème.

Solution apportée

Pour résoudre ces problèmes, nous avons opté pour une programmation complète de la machine, incluant la suppression des défauts AdBlue et la désactivation des dispositifs antipollution. Cette approche radicale a permis de mettre en OFF l’ACM gérant les données de post-traitement, assurant ainsi une solution durable et efficace.

Processus de réalisation

- Utilisation de l’outil Vocom de la concession en mode ingénierie développeur

- Flashage des données et programmation du boîtier de commande moteur EMS2.3.

- Intégration des nouvelles valeurs de fonctionnement.

- Suppression définitive du système AdBlue et du FAP.

- Désactivation du recyclage des gaz EGR.

Résultats obtenus

Cette solution a permis de retrouver toute la puissance et le couple de la machine. En éliminant les contraintes liées aux systèmes de post-traitement des gaz, la chargeuse L180H Volvo fonctionne désormais de manière optimale, sans les interruptions causées par des régénérations inefficaces ou des capteurs NOx défaillants.

Conclusion

Le problème de régénération sur Volvo L180H peut être résolu efficacement par une approche de suppression du système AdBlue et de désactivation des dispositifs antipollution. Cette intervention permet non seulement de résoudre les défauts immédiats mais également d’assurer une performance optimale à long terme pour la machine.

Prise de contact

N’hésitez pas à nous contacter pour obtenir plus d’informations sur nos solutions de dépannage pour les problèmes d’Adblue sur votre chargeuse ou pelle Volvo. Nos experts sont à votre disposition pour répondre à toutes vos questions et vous aider à choisir la solution la plus adaptée à vos besoins