Les avantages de la suppression des dispositifs NOx sur le Scania R730 EEV

Fonctionnement du moteur et du système antipollution SCR du Scania R730 (DC16 21)

Le moteur DC16 21 de Scania développe 730cv et 3500Nm de couple. Il est équipé d’un calculateur EMS S8 qui gère son fonctionnement et contrôle également le turbo à géométrie variable monté sur ce R730. La boite GRSO925R permet d’encaisser le couple élevé. Le système de post-traitement des gaz utilisé sur les versions EEV de Scania est basé sur le modèle SCR uniquement. Enfin, Il n’y a pas de filtre à particules ni de vanne EGR. En cas de défaut SCR, une alerte moteur surgit avec l’option NOx Control Reduction qui réduit les performances moteur en cas de problème au niveau du contrôle des oxydes d’azote.

Optimisation de puissance pour le dépannage. (Ensemble à parfois 90T)

Le chiptuning est une technique utilisée pour optimiser les performances d’un moteur en modifiant les paramètres de gestion moteur (EMS) via un logiciel de reprogrammation. Il permet de modifier les paramètres tels que la quantité d’air et de carburant injectée, la pression de suralimentation, les temps d’ouverture des soupapes, etc.

Dans notre cas, pour l’optimisation de puissance de Scania R730, nous avons modifié les paramètres d’injection pour augmenter la puissance de 730cv à 800cv et le couple de 3500Nm à près de 4000Nm. De plus, Cette optimisation a permis d’améliorer les performances du camion pour les besoins de dépannage lors de lourdes charges.

Suppression problème NOx R730

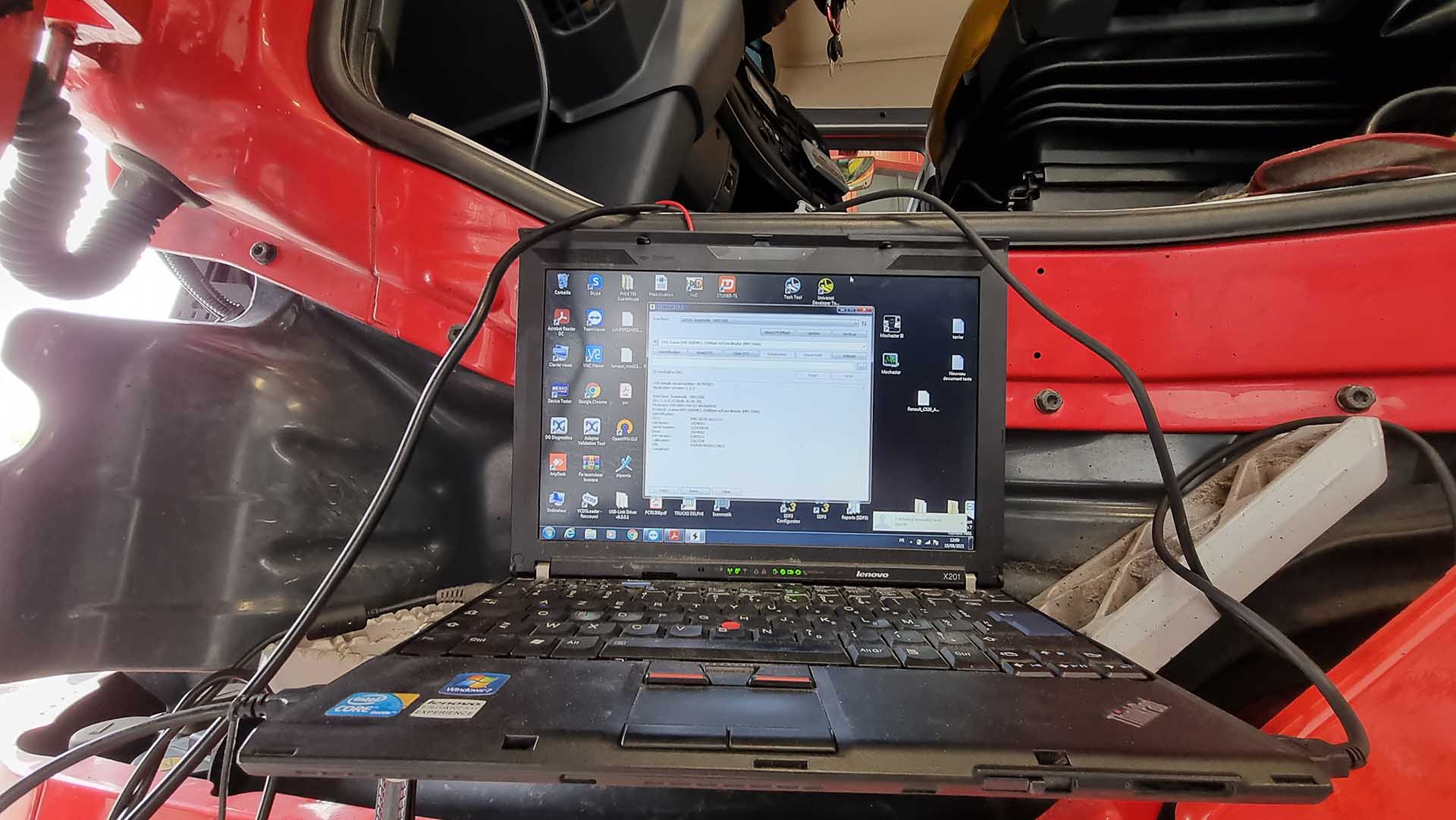

Pour supprimer les défauts liés aux NOx via l’EMS (Engine Management System) et l’EEC3 (Engine Emission Control), il est nécessaire de procéder à une reprogrammation du logiciel de gestion moteur. Cette reprogrammation peut être effectuée en utilisant un logiciel de reprogrammation Scania ainsi que des outils de gestion des différentes cartographies. En accédant directement aux paramètres de l’EMS via un outil de diagnostic nous avons donc accès à tous les réglages tels que pourraient le faire les ingénieurs en Suède.

Notons que lorsque l’on procède à la suppression du contrôle des NOx via l’EMS et l’EEC3, la remontée des défauts sur le système CANBus (Controller Area Network Bus) n’est plus possible. Cela signifie que tous les problèmes du au système d’adblue disparaissent, ils ne seront plus signalés via le système de diagnostic de bord.

Pourquoi avoir supprimé le contrôle des NOx ?

Ce camion, bientôt équipé d’un échappement libre pour effectuer des rassemblements entre passionnés sur terrain clos et privés ne pourrait pas être utilisé sans rouler en échappement libre avec l’adblue activé. Par conséquent, ne pas désactiver l’adblue afficherait des voyants et une réduction des performances moteur. La désactivation pour utiliser le véhicule en libre peut se faire par simple interrupteur.

Vous pouvez accéder à notre base de données sur tous les Scania ainsi que les possibilités de reprogrammation.