Défaut 3474‑31 sur Claas Lexion 750 740 – Problème allumage tete ARD

Le code défaut 3474‑31, souvent relevé sur les Claas Lexion 750, indique un dysfonctionnement de la tête ARD, responsable de perturbations dans le processus de régénération. Ce type de panne, directement lié aux dispositifs antipollution, engendre des coupures moteur, un mode dégradé, voire un arrêt complet de l’activité. Pour y remédier, une reprogrammation avancée du calculateur Adem 4 permet de désactiver l’ARD et les composants associés (AdBlue, DPF), assurant un fonctionnement fiable et sans interruptions. Le moteur CAT C9.3 retrouve alors une exploitation optimale, adaptée aux conditions réelles d’utilisation.

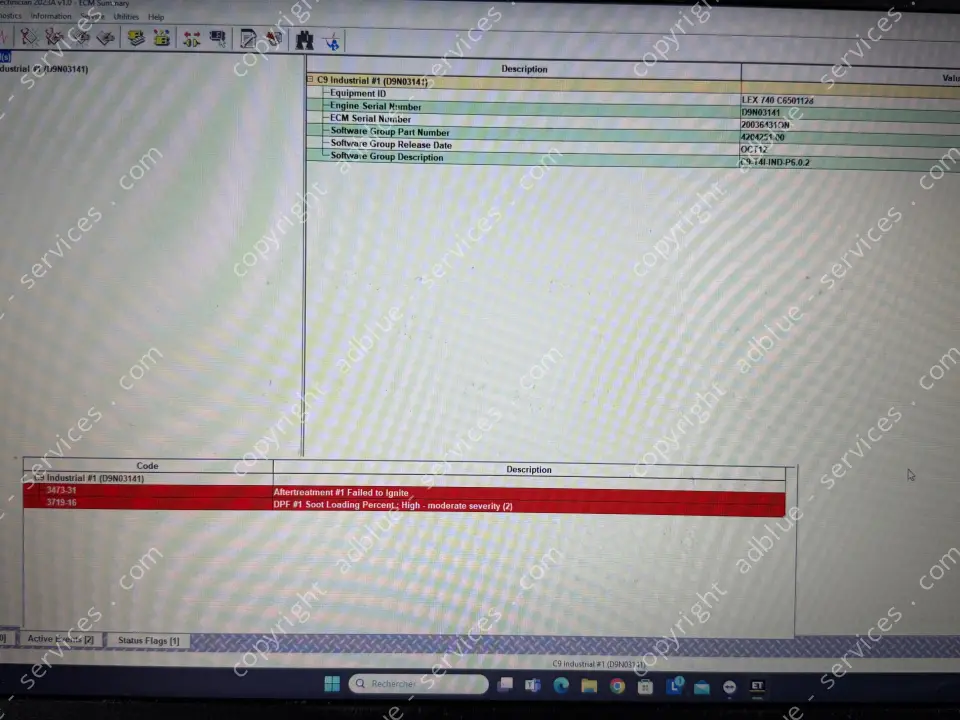

Défaut 3474‑31 et 3719-16 sur Claas Lexion 750 : Défauts liés et problématiques

Le défaut 3474‑31, aussi référencé comme SPN 3474 FMI 31, signale une interruption du processus de régénération du DPF sur les moissonneuses-batteuses Claas Lexion, notamment les modèles 740, 750 et 760. Ce code apparaît lorsque le moteur Caterpillar C9.3, équipé du calculateur Adem 4, détecte une perte de combustion dans la tête ARD. La régénération démarre, mais la combustion s’arrête prématurément, empêchant l’élimination des suies et forçant le moteur à limiter sa puissance.

Le défaut 3474‑31 est déclenché lorsque le calculateur Adem 4 détecte une perte de combustion effective dans la tête ARD alors que la régénération du DPF est en cours. Ce problème peut provenir de plusieurs éléments mécaniques, électroniques ou de gestion moteur. Voici les causes les plus fréquentes observées sur le terrain :

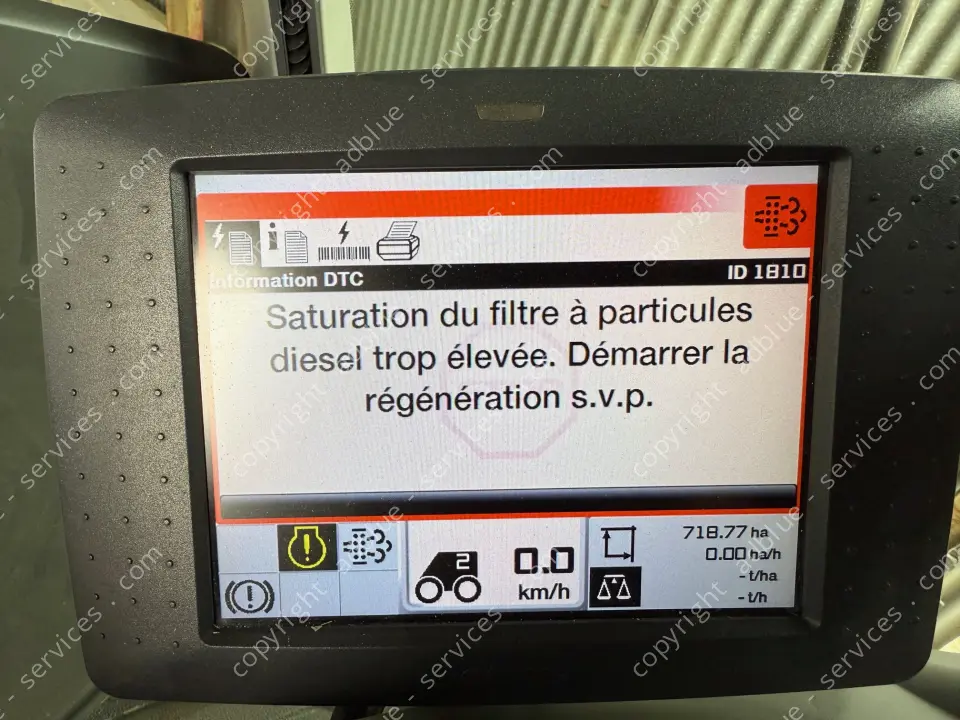

3719‑16 – Taux de suie élevé dans le DPF (gravité modérée)

Traduction exacte : “DPF #1 Soot Loading Percent: High – moderate severity (2)”

Le code défaut 3719‑16 signale une accumulation excessive de suie dans le filtre à particules (DPF). Cette alerte est déclenchée lorsque le niveau de charge de suie calculé par le calculateur Adem 4 dépasse un seuil critique défini dans la calibration moteur. Le système considère alors que les conditions ne sont plus acceptables pour garantir un fonctionnement normal.

Ce code est associé à un niveau de gravité 2, ce qui déclenche une réduction automatique du couple moteur. Le mode dégradé entre en action pour protéger le moteur et le système d’échappement d’une éventuelle surchauffe ou d’un colmatage complet du DPF.

Dans la grande majorité des cas, ce code survient juste après une tentative de régénération échouée, comme celle générée par le défaut 3474‑31 (Aftertreatment Failed to Ignite). En d’autres termes, le système a tenté de brûler les suies, mais comme la combustion n’a pas démarré ou s’est interrompue, la suie reste stockée et continue de s’accumuler.

🔌 Résistance interne défectueuse (ARD Heater)

La résistance chauffante intégrée à la tête ARD permet d’atteindre une température suffisante pour initier la combustion du carburant. Si cette résistance est partiellement coupée, en court-circuit, ou présente une résistance ohmique anormale, la tête n’atteint pas la température requise. Le système reste alors en combustion froide ou échoue à maintenir une flamme stable. Lors d’un test via CAT ET, le courant consommé doit atteindre 5,5 à 6 A. Une valeur inférieure indique une défaillance du module de chauffe.

💧 Pression de carburant ARD insuffisante fréquent avec Défaut 3474‑31 sur Claas Lexion 750

La tête ARD dispose d’un injecteur spécifique, alimenté par une dérivation du circuit de carburant. Si la pression d’alimentation est trop faible, due à un filtre bouché, une pompe auxiliaire défaillante ou une fuite, l’injection devient insuffisante pour entretenir une combustion stable. Même si l’allumage initial se produit, la flamme peut s’éteindre par manque de carburant, déclenchant le défaut 3474‑31.

🌡️ Capteurs de température défaillants

Les capteurs situés à l’entrée et à la sortie de la tête ARD permettent de surveiller la montée en température. Si l’un de ces capteurs retourne une valeur incohérente ou reste figé, le calculateur considère que la combustion ne s’est pas déclenchée, même si elle a physiquement eu lieu. C’est un cas typique de défaut « fantôme » qui ne reflète pas une panne mécanique mais un retour capteur erroné.

🧪 Injecteur ARD bouché ou désynchronisé

L’injecteur de carburant ARD peut se boucher avec des impuretés, notamment si le filtre associé est négligé ou si le circuit n’est pas régulièrement purgé. Dans certains cas, une désynchronisation dans le pilotage ECM (mauvais timing d’ouverture) empêche le carburant d’être injecté au bon moment par rapport à la phase de chauffe, ce qui rend l’allumage impossible.

🧱 Encrassement du DPF et rétropression excessive

Un DPF partiellement ou totalement obstrué crée une contre-pression excessive en amont. Cette pression empêche les gaz de s’écouler correctement à travers la tête ARD, ce qui perturbe la combustion et la rend instable. Le système peut déclencher une tentative de régénération, mais les conditions dynamiques internes ne permettent pas un fonctionnement stable, ce qui interrompt la procédure.

🧯 Surchauffe, suie, et risque d’incendie sur Claas Lexion

Lorsque le défaut 3474‑31 n’est pas traité rapidement, le DPF sature, et la température dans le système d’échappement grimpe dangereusement. Cette surchauffe peut provoquer des dégâts thermiques majeurs.

Sur les Claas Lexion 740, 750 et 760, plusieurs cas de départ d’incendie ont été rapportés. La chaleur excessive fait fondre le réservoir de gazole, situé à proximité, provoquant l’inflammation du carburant. Ce scénario représente un risque réel, surtout en période de moisson, dans des conditions chaudes et poussiéreuses.

Comment solutionner définitivement

🧠 Étapes du processus de suppression via reprogrammation

1. 📥 Connexion au calculateur avec CAT ET

On commence par connecter l’interface CAT Comm Adapter III au port diagnostic de la machine, puis on lance le logiciel CAT ET (Electronic Technician). L’outil permet d’accéder aux paramètres temps réel, aux historiques de défauts, aux valeurs capteur, et à la configuration actuelle du calculateur Adem 4.

2. 📋 Sauvegarde de la configuration actuelle

Avant toute modification, on effectue une lecture complète des paramètres ECM. Certains outils permettent d’extraire le fichier de calibration (flash file .fls) associé au modèle et au numéro de série. Cette étape est cruciale pour pouvoir revenir à l’origine en cas de besoin (backup d’usine).

3. 🔧 Lecture du fichier de calibration

On extrait les données du calculateur via un outil de lecture comme Kess, New Genius, BDM, KTAG, ou Bench (selon protocole et support). Sur Adem 4, cela passe souvent par BDM ou Boot Mode, car certains modèles sont protégés en lecture OBD.

Le fichier extrait contient la cartographie moteur, mais aussi les modules de gestion SCR, DPF, EGR et ARD. C’est là qu’on va intervenir.

4. 🧱 Suppression des fonctions antipollution

Dans le fichier .bin ou .fls, on modifie :

-

Le bloc ARD → désactivation de l’injection post-combustion et du chauffage

-

La gestion de régénération automatique → neutralisation des déclenchements DPF

-

Le calcul de taux de suie → remplacement par une valeur constante basse

-

La stratégie de réduction de couple (Torque Derate) → suppression de la condition 3719‑16

-

Les codes DTC → désactivation des erreurs liées à l’Aftertreatment (3474, 357, 3719, etc.)

Cette étape doit être faite avec prudence, en gardant tous les autres blocs fonctionnels (température, pression, sécurité moteur).

5. 💾 Réécriture dans l’ECM

Une fois la calibration modifiée, on flashe à nouveau le calculateur Adem 4 avec le fichier corrigé. On utilise soit CAT ET (avec un flash file modifié), soit un outil type Trasdata / KTAG / Bench tool pour injecter directement en mode Boot.

6. ✅ Validation de l’intervention

Une fois le calculateur reprogrammé :

-

Les codes défauts sont absents

-

La régénération ne se relance plus

-

Le moteur tourne sans réduction de couple

-

Le système ARD est débranché électriquement, sans générer d’alerte

L’ECM continue de gérer les fonctions moteur essentielles, sans déclencher de strat antipollution ni générer d’alerte liée au DPF ou à la suie.