Mode dégradé Doosan DX180 : solution au défaut AdBlue SCR

Le Mode dégradé Doosan DX180 est un problème courant dans les travaux publics. Il est souvent causé par une défaillance du système AdBlue (SCR). Dès qu’un défaut apparaît, la machine peut perdre en puissance. Cela peut bloquer complètement l’activité sur le chantier. Pour éviter ce type de désagrément, une solution existe : la suppression du système AdBlue et des dispositifs d’émissions. Cette modification permet de retrouver une machine fiable, sans perte de puissance.

En effet, la reprogrammation de l’ECU Adem IV, qui pilote le moteur Perkins 1204F, permet d’optimiser les paramètres moteur. Cette intervention améliore à la fois les performances et la fiabilité sur le terrain.

Diagnostic des défauts liés au mode dégradé Doosan DX180

Avant toute intervention, il est essentiel de réaliser un diagnostic complet du système de dépollution. Cela permet d’identifier précisément la cause des dysfonctionnements. Il est fréquent que des erreurs réapparaissent, même après avoir remplacé plusieurs pièces. Dans ce contexte, désactiver les systèmes à l’origine du mode dégradé devient souvent la solution la plus logique.

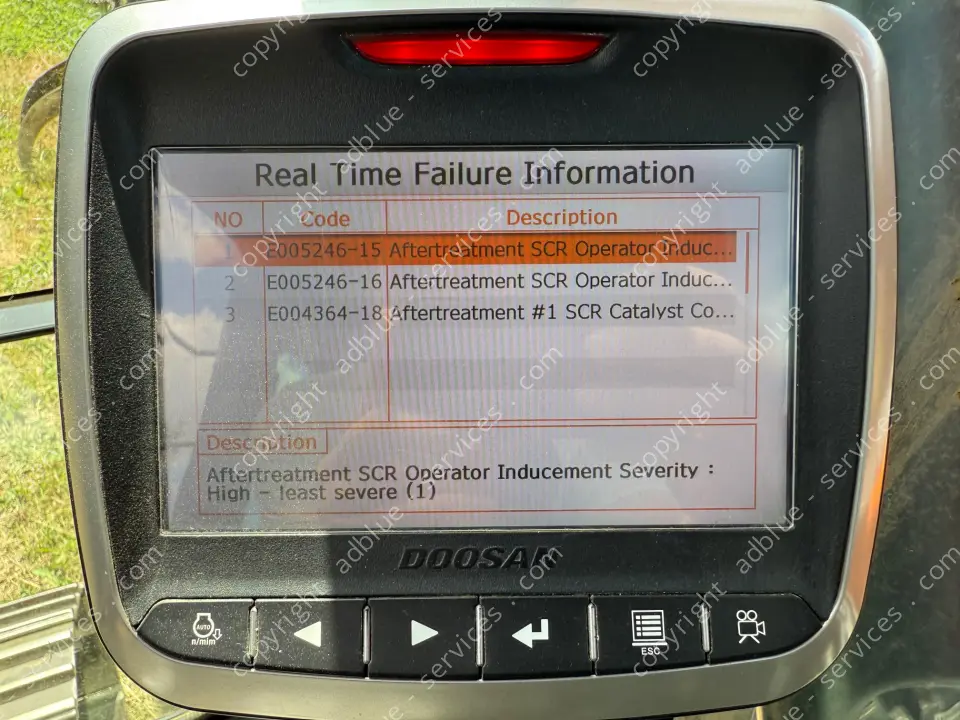

Lors de l’analyse d’un Doosan DX180 équipé de l’ECU Adem IV, plusieurs défauts ont été détectés. Voici les principaux :

-

E005246-15 – Aftertreatment SCR Operator Inducement Severity: High – least severe (1)

Ce code signale un défaut de sévérité élevée, bien que minimale. Il peut provenir d’un capteur NOx défaillant ou d’un AdBlue de mauvaise qualité. Cela entraîne une perte de puissance et l’entrée en mode dégradé. -

E005246-16 – Aftertreatment SCR Operator Inducement Severity: High

Ce code indique un problème persistant dans le système SCR. Une ligne bouchée ou un catalyseur endommagé peut en être la cause. Ce défaut peut engendrer une surconsommation de carburant et des arrêts inattendus. -

E004364-18 – SCR Catalyst Conversion Efficiency

Ici, l’alerte concerne une faible efficacité de conversion des gaz polluants. Un catalyseur vieillissant ou une contamination de l’AdBlue peuvent expliquer ce défaut. Ce problème augmente les émissions et accentue le risque de mise en mode dégradé.

Processus de reprogrammation pour enlever le Mode dégradé Doosan DX180

Le processus commence par un diagnostic électronique à l’aide d’outils comme CAT ET ou Perkins EST. Ces outils identifient les défauts liés au Mode dégradé Doosan DX180, directement sur le moteur Perkins 1204F.

Ensuite, le fichier moteur est lu depuis l’ECU (Adem IV). Ce fichier contient tous les paramètres de fonctionnement. Il est ensuite analysé pour localiser les fonctions liées à l’AdBlue, au DPF et à l’EGR. À ce stade, les ingénieurs identifient les causes du passage en mode dégradé.

Une fois les causes ciblées, les modifications logicielles sont appliquées. Elles permettent de désactiver le système AdBlue, d’émuler le FAP (DPF) et de supprimer les erreurs déclenchant la perte de puissance. Les checksums sont recalculés pour garantir l’intégrité du fichier.

Enfin, le fichier modifié est injecté dans le calculateur. Une série de tests est réalisée sur chantier pour valider les performances. Cette méthode assure la suppression définitive du Mode dégradé Doosan DX180, avec un moteur pleinement opérationnel.

En savoir plus sur Doosan et les désactivations d’émissions

Consultez notre section dédiée à la gamme Doosan pour découvrir toutes nos solutions de suppression AdBlue, DPF et EGR, compatibles avec de nombreux modèles de pelles, chargeuses et autres machines du BTP.

👉 Voir tous les articles Doosan

Vous travaillez aussi sur des moteurs Perkins (404F, 854F, 1204F, etc.) ou des calculateurs Adem IV ?

Accédez à notre page dédiée aux interventions sur moteurs Perkins pour en savoir plus sur les possibilités de reprogrammation, diagnostic et suppression d’émissions.

👉 Voir les interventions sur moteurs CAT/Perkins