Erreur Adblue sur chargeuse Hitachi – Résoudre définitivement

Introduction

Le défaut AdBlue sur Hitachi ZW220 est un problème connu qui affecte directement la productivité sur chantier. Cette chargeuse, équipée d’un moteur Cummins QSB 6.7 piloté par un calculateur CM2350, est sensible aux dysfonctionnements du système SCR (Selective Catalytic Reduction). Lorsqu’un défaut SCR apparaît, la machine entre généralement en mode dégradé, avec une perte progressive de puissance. Dans certains cas, elle peut même finir par s’arrêter complètement, rendant toute intervention impossible sans diagnostic avancé.

Pour éviter ces interruptions coûteuses, nous proposons une suppression complète des dispositifs d’émissions : AdBlue, FAP (filtre à particules) et EGR (recirculation des gaz d’échappement). Cette opération élimine les sources de panne fréquentes liées à l’encrassement, aux capteurs défaillants ou aux cycles de régénération mal exécutés. Le moteur retrouve alors une stabilité de fonctionnement, sans limitation logicielle.

Diagnostic du défaut AdBlue sur Hitachi ZW220 – Message « Le système SCR urée est cassé »

Lors de notre intervention sur une Hitachi ZW220 équipée du moteur Cummins QSB 6.7 et du calculateur CM2350, le tableau de bord affichait le message explicite :

« Le système SCR urée est cassé », accompagné d’icônes d’alerte liées au système de post-traitement des gaz.

Ce message indique un dysfonctionnement du système SCR (Selective Catalytic Reduction), responsable de l’injection d’AdBlue dans la ligne d’échappement. Lorsqu’un défaut critique est détecté, le calculateur déclenche une stratégie de réduction de puissance, puis un blocage progressif de l’engin s’il n’y a pas de correction.

-

Ces codes sont tirés du guide Cummins Tier 4 pour moteurs QSB 6.7 (valide pour CM2350)

-

3238/SPN 4340 FMI 4 – Diesel Exhaust Fluid Line Heater 1 Circuit – Voltage Below Normal

Tension basse dans le circuit de réchauffeur AdBlue.

👇 Peut causer défaut « SCR urée cassé ». -

3258/SPN 4340 FMI 5 – Diesel Exhaust Fluid Line Heater 1 State – Current Below Normal or Open Circuit

Signal ouvert ou faible courant, souvent dû à un réchauffeur cassé ou câblage défectueux. -

3559/SPN ??? FMI ? – Diesel Exhaust Fluid Dosing Unit – Voltage Below Normal

Unité de dosage d’urée sous tension, injecteur AdBlue inactive. -

3568/SPN 5394 FMI 7 – Diesel Exhaust Fluid Dosing Valve – Mechanical system not responding or out of adjustment

Défaut mécanique ou commande défaillante de vanne AdBlue. -

3714/SPN 1569 FMI 11/31 – Engine Protection Torque Derate

Le moteur passe en mode réduction puissance dès qu’un code SCR critique est détecté. -

5631/SPN 6928 FMI 31 – SCR System Cleaning Inhibited Due to System Timeout

Stratégie SCR suspendue à cause d’un timeout, signe d’une défaillance persistante.

-

Processus de reprogrammation pour défaut AdBlue sur Hitachi ZW220

Lecture de l’ECU CM2350

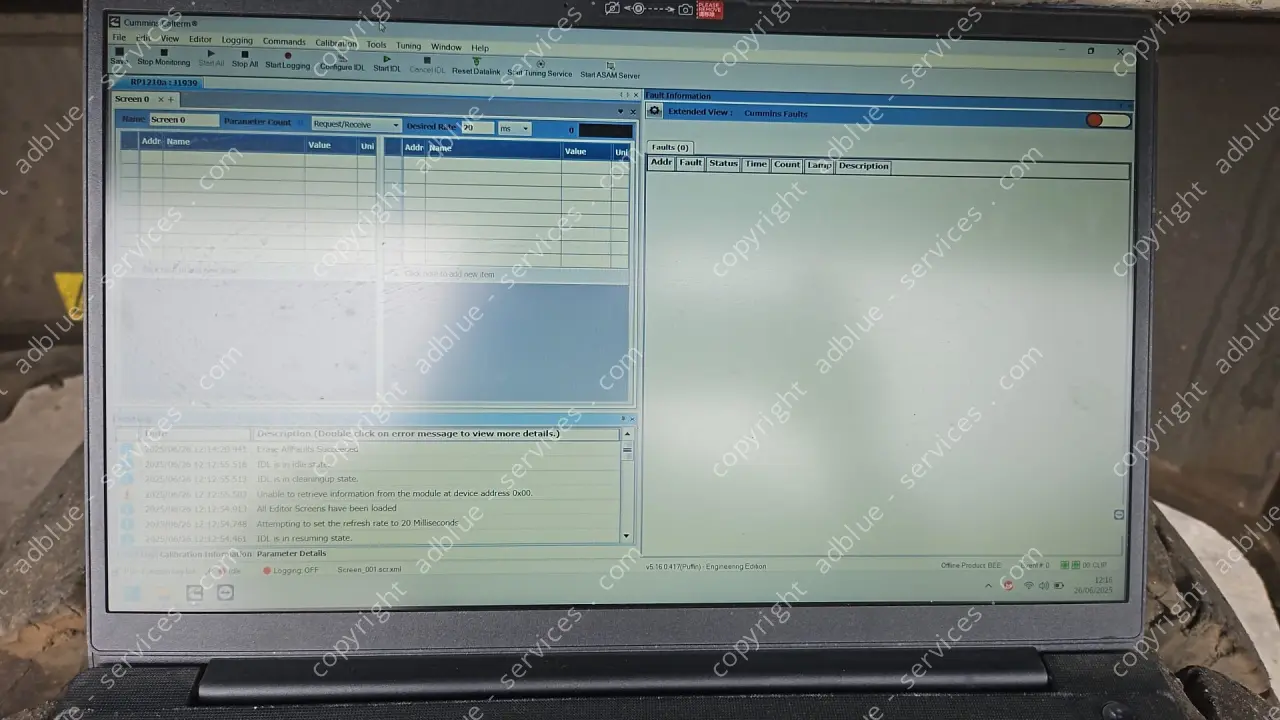

La lecture du fichier moteur s’effectue via Calterm (version 4 ou 5), avec un driver Cummins comme Inline 7 ou Nexiq USB Link.

L’opération peut se faire sur banc ou directement via la prise diagnostique, en fonction de la sécurité active dans l’ECU CM2350.

Le fichier extrait est au format .bin ou .cal, selon la méthode utilisée (lecture directe ou via Workstation).

Ce fichier contient l’ensemble des paramètres moteur, y compris les tables de gestion SCR, DPF, EGR et les logiques de défaut.

Analyse des blocs antipollution

Une fois le fichier chargé dans Calterm, plusieurs blocs critiques sont analysés pour identifier les fonctions à neutraliser.

L’objectif est de cibler précisément les éléments responsables des déclenchements de défauts et des stratégies de limitation moteur.

Blocs analysés :

-

Aftertreatment Diagnostic Parameters : déclencheurs d’inducement et délais

-

DEF Control Parameters : contrôle de la pompe et de l’injecteur AdBlue

-

DPF Sooth Load Estimation : estimation et seuils de régénération du filtre

-

EGR Control Strategy : activation ou désactivation de la vanne EGR

-

Fault Management : traitement, seuils et masquage des DTCs

Les trames CAN broadcastées sont également vérifiées, car certaines ECU exigent que certaines valeurs restent présentes.

Même sans capteurs physiques, les données doivent rester logiquement cohérentes pour éviter la détection de suppression.

Suppression et reprogrammation

Après analyse, les fonctions polluantes sont supprimées via une modification calibrée de la cartographie moteur.

On n’agit pas en surface : la logique complète est neutralisée pour empêcher toute activation future.

Modifications effectuées :

-

Désactivation de l’injection AdBlue et des cycles SCR

-

Blocage des régénérations DPF et des calculs de suie

-

Suppression ou inhibition des défauts bloquants (ex. 3714, 3238, 3559)

-

Émulation de capteurs critiques avec valeurs constantes réalistes (NOx, température, pression)

Cette reprogrammation permet d’éviter les réactions classiques : réduction de couple, minuteur de blocage moteur ou codes persistants.

Chaque action est contrôlée pour garantir la stabilité du moteur, même dans des conditions de charge élevée.

Calcul des checksums et validation

Une fois les modifications effectuées, un recalcul des checksums est indispensable pour garantir la validité logicielle.

Selon la structure du fichier, ce recalcul peut être effectué dans Calterm ou via un outil tiers externe.

Chaque segment modifié est vérifié ligne par ligne afin d’éviter tout risque de corruption.

Une inspection manuelle est également réalisée pour prévenir les erreurs critiques (adresse invalide, incohérence structurelle…).

Réécriture dans l’ECU et tests terrain

Le fichier corrigé est injecté dans le CM2350 via Calterm, généralement en mode calibration (pas de full flash nécessaire).

Après redémarrage, aucun défaut ne doit apparaître et la puissance moteur est immédiatement disponible.

Des tests à chaud et sous charge sont réalisés pour valider la stabilité, l’absence de stratégie d’inducement et la cohérence des valeurs CAN.

La chargeuse peut alors fonctionner sans injection d’AdBlue, sans régénération DPF, et sans limitations électroniques.

En savoir plus sur Hitachi et les désactivations d’émissions

Consultez notre section dédiée à la gamme Hitachi pour découvrir toutes nos solutions de suppression AdBlue, DPF et EGR, compatibles avec de nombreux modèles de chargeuses, pelles et autres engins de chantier.

👉 Voir tous les articles Hitachi

Vous travaillez aussi sur des moteurs Cummins (QSB, QSL, ISB, etc.) équipant d’autres machines ?

Découvrez notre page dédiée aux interventions spécifiques sur moteurs Cummins, quel que soit le constructeur d’origine.

👉 Voir les interventions sur moteurs Cummins