NOx fault CAT 966M: Purge problem Adblue

The Machine: Caterpillar 966M loader: CAT C9.3 Tier 4F engine

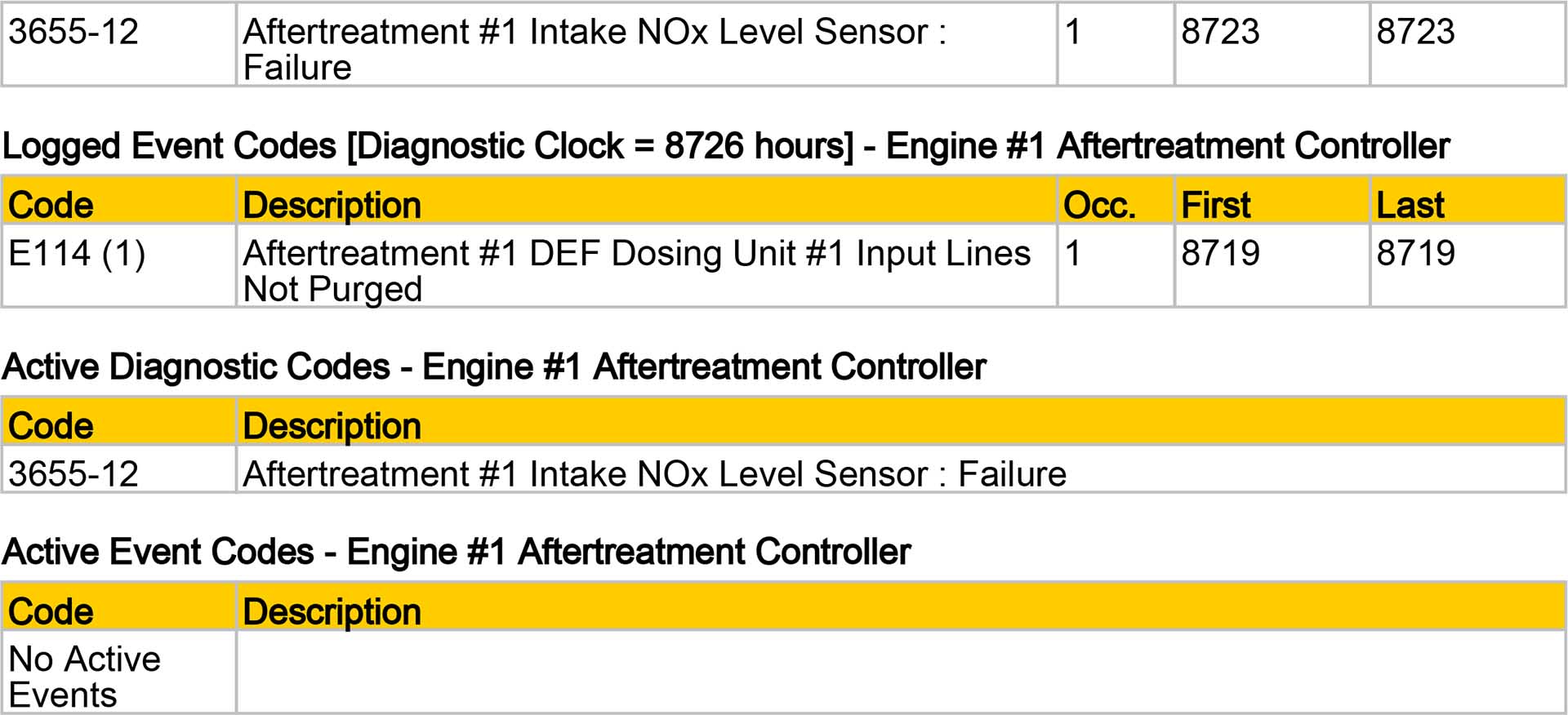

On this CAT 966M loader, we encountered a problem with the exhaust aftertreatment system. In particular, the SCR system was affected. The following faults have been identified:

Error 3655-12 (NOx fault Cat 966M) indicates a failure of the aftertreatment intake NOx level sensor #1. The code is in ACTIVE status, resulting in a permanent fault on the instrument panel and a restriction of loader power.

Code E114 indicates a fault in the AdBlue dosing unit. Code E114 indicates that the input lines of the DEF #1 aftertreatment #1 dosing unit need to be purged. To determine the cause of the problem, we recommend checking the lines for blockages, checking the pressure in the lines, and then continuing diagnosis. The lines may be clogged with impurities or under-pressurized, or the DEF dose unit may be faulty.

Adblue Services solutions

Our software solution solves the NOx fault on the CAT 966M by inhibiting operation of the after-treatment system. By rewriting a new program, we were able to completely eliminate the use of the DPF (particulate filter) and the SCR (Selective Catalytic Reduction) unit. This means that the ARD connector can be disconnected without any errors occurring.

Prior to the implementation of this solution, the vehicle encountered errors such as the aftertreatment system's intake NOx level sensor and the DEF dosing unit's input lines not being purged. These errors have now been resolved, and physical devices such as the DEF unit are completely inactive.

To implement this solution, we proceeded to flash the data on the vehicle. This involves replacing the existing software with a new program that inhibits the operation of the aftertreatment system. This new program is installed in the flash memory of the engine ECU, optimizing vehicle performance while guaranteeing stable, safe operation.

In conclusion, our software solution enables the NOx fault on the CAT 966M to be resolved efficiently and reliably. This solution delivers a significant improvement in vehicle performance, while guaranteeing stable, safe operation. Below is the dashboard, with no change of parts, and no fault.

Operations possible on the entire Caterpillar range

Our expertise enables us to work on all Cat machines, including all engines and ECUs. You can find an overview and feasibility of CAT machines on our explanatory page, as well as all our previous operations here.