Problem Adblue Braud 9070N : Motor FPT CNH Industrial

Summary of the situation

On this New Holland Braud straddle tractor, equipped with the FPT engine with ECOBlue™ SCR (selective catalytic reduction) Technology, we have encountered a problem concerning various faults on the SCR system. To begin with, we'll list various fault codes, followed by their probable cause, possible methods of resolution, and the possibility of resolving the problem once and for all.

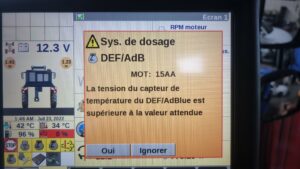

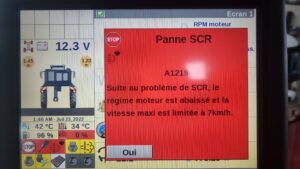

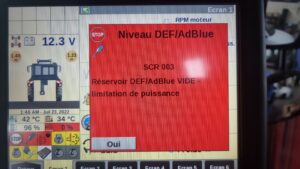

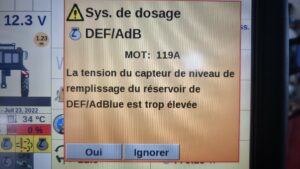

Defect codes in question

They are numerous and prevent total vehicle operation.

This machine has various fault codes SCR code 007 indicating an AdBlue injection fault and torque reduction, code A1219 indicating an SCR fault which, following this code, lowers the engine speed and limits the speed to 7km/h, code 9AEA indicating a CAN timing error on the DEF quality sensor, code 15AA indicating an incorrect voltage on the DEF temperature sensor (higher than expected), code 119A indicating a voltage fault on the tank level sensor (voltage too high). In addition, a SCR003 fault indicates a fault relating to the level of adblue in the tank (EMPTY).

Possible causes of an Adblue Braud problem

First, let's look at the 9AEA fault:

Fault 9AEA indicates a CAN timing error from the DEF quality sensor. The CAN (Controller Area Network) system is a communication network used to exchange data between the various components of a vehicle. If the CAN system is not functioning correctly, this can lead to communication problems between the various vehicle components, affecting vehicle operation.

There are a number of reasons why the CAN system may not operate correctly and cause a 9AEA fault. Here are some examples of problems that can cause a CAN timer error:

- A damaged or faulty cable or connector

- A faulty or incorrectly installed sensor

- A problem with the engine ECU or another CAN system component

- A software or CAN system configuration problem

Relationship between faults 9AEA, 15AA and 119A

Faults 9AEA, 15AA and 119A may all be linked to incorrect operation of the selective catalytic reduction (SCR) system on your Braud 9070N straddle tractor. Fault 9AEA indicates a CAN timing error from the DEF quality sensor, fault 15AA indicates an incorrect voltage from the DEF temperature sensor, and fault 119A indicates a voltage fault from the tank level sensor. If these sensors are not working properly, this may affect the operation of the SCR system and lead to problems with the machine.

Sensor overvoltage can actually cause problems with the Controller Area Network (CAN), leading to timing errors. The CAN network is a communication network used to exchange data between the various components of a vehicle. If a sensor sends data with an incorrect voltage to the CAN network, this can disrupt communication between the various components and cause timing errors, such as timeouts.

Power surges can be caused by a number of factors, such as a problem with the sensor itself, a damaged cable or connector, or an external power surge. If you suspect that sensor overvoltages may be the cause of timing errors on the CAN network.

Limiting torque, engine speed and speed due to NOx control

Torque limiting and rev-limiting is managed by the engine control unit (ECU), which can reduce power and engine speed to protect the vehicle in the event of a breakdown or malfunction. The maximum speed limit of 7 km/h can be imposed by the speed control system, which can limit vehicle speed in the event of a problem with the SCR system or other vehicle components.

Here are some logical steps that may help you solve the problems described with your Braud 9070N straddle loader:

- Check the AdBlue level in the tank and make sure it's sufficient. If the level is low, refill the tank with AdBlue.

- Check the condition of the AdBlue injection hose and make sure it's not clogged or damaged. If the hose is damaged, replace it.

- Check that the AdBlue tank level sensor is working properly. If the sensor is faulty, replace it.

- Check the configuration of the ECU and other SCR system components, and make sure they are correctly configured. If necessary, reset the ECU or update the software.

- If problems persist, it may be necessary to replace faulty or damaged components of the SCR system, such as the DEF temperature sensor or DEF quality sensor.

- Check the electrical connections of the sensors concerned and make sure they are sound and correctly connected. Also check the condition of the cables and make sure they are not damaged or corroded.

- Use a multimeter to measure the voltage at the terminals of the sensors concerned, and compare the results with the voltage values specified by the manufacturer. If the voltage is higher or lower than the specified values, this could indicate a problem with the sensor or associated cables.

- Test the sensors with another measuring device, such as an oscilloscope, to check their operation. If the sensors are not working properly, they may be defective and should be replaced.

- Check the voltage of the vehicle's power supply and ensure that it is stable and complies with the manufacturer's specifications. If the power supply voltage is unstable or abnormally high, this could affect sensor operation and lead to incorrect voltages.

- Check wiring harness completely.

What if, after changing all these elements, it still doesn't work?

In our case, the owner has changed numerous parts and sensors, checked the entire wiring harness, checked the weights, but the problem persists and the vehicle has been in the garage for 6 months, unable to be used. An Adblue Braud problem is responsible for the loss of sales over 6 months, and more 'drastic' solutions are needed.

Total deactivation of the SCR system is therefore possible, and avoids all these types of problems, especially when there is no other possible solution. Reprogramming the EDC17CV41 ECU allows you to deactivate the entire adblue system system, preventing faults from being displayed on the dashboard. Sensors can also be disconnected, so AdBlue consumption will be zero, with no apparent error. In addition, emission-related restrictions such as speed, torque and engine speed will no longer apply. However, in the event of an AdBlue Braud problem, we take care not to always focus on engine-related safety issues, but solely on emissions.

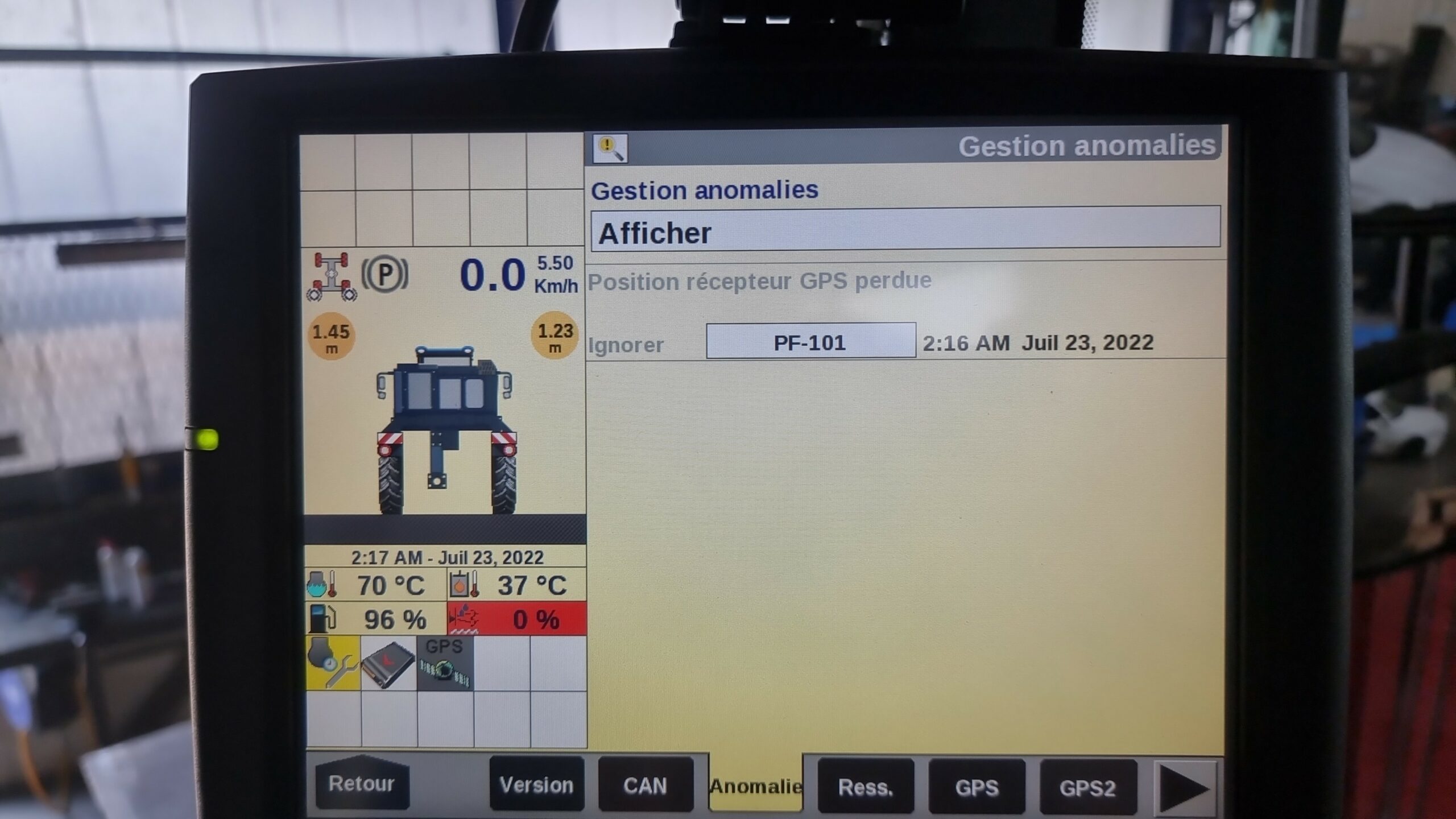

After our intervention, there were no more faults in the ECU memory, as you can see below.

You can also find other articles on agricultural machinery as well as technical details on New Holland machines. New Holland machines machines we can work on.