PC240-LC10 regeneration problem: Solving malfunctions on your Komatsu excavator

The Komatsu PC240-LC10, equipped with a 132 kW SAA6D engine and CM2250 ECU, frequently encounters regeneration problems affecting its overall performance. These failures, linked to anti-pollution systems such as DPF, SCR and NOx sensors, cause engine restrictions and recurrent alerts. If you're facing a PC240-LC10 regeneration problem, it's essential to intervene to eliminate these faults and restore your machine's full potential.

Frequent emission-related malfunctions on the PC240-LC10

The emission control systems built into the Komatsu PC240-LC10 often generate faults that disrupt its normal operation. Among the main problems are :

- Code 3317: A temperature anomaly upstream of the DPF prevents regeneration cycles from being triggered, resulting in engine restrictions.

- Code 3134: This fault indicates a clogged particulate filter, requiring immediate action to avoid power loss.

- Code 2375: An error in the NOx sensor compromises SCR operation, unnecessarily increasing AdBlue consumption.

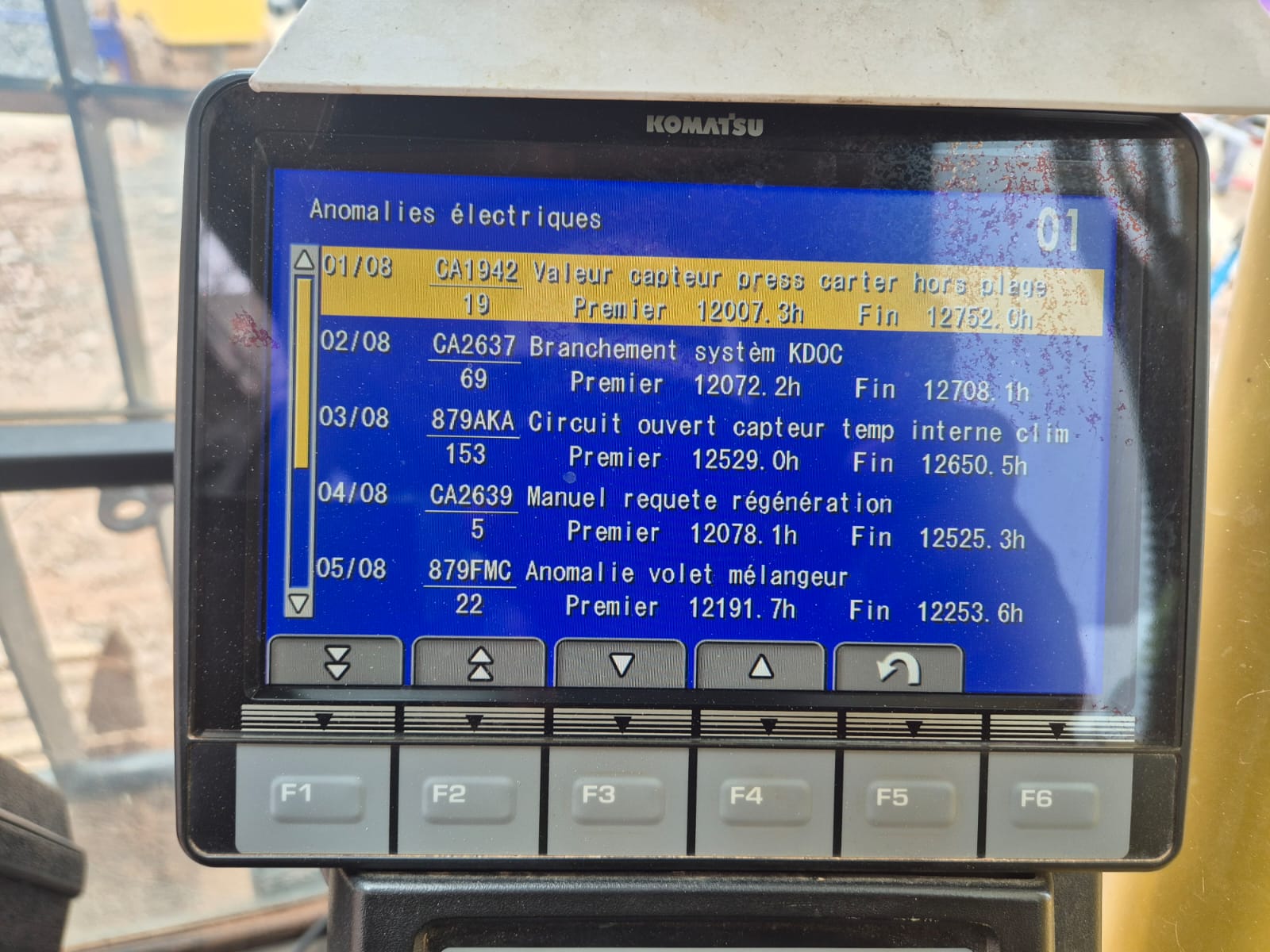

- Code 1942: Abnormal crankcase pressure, often caused by incomplete cycles, can damage the system.

These regeneration problems on PC240-LC10 reduce productivity, increase maintenance costs and disrupt the operation of your excavator.

A technical solution thanks to Calterm

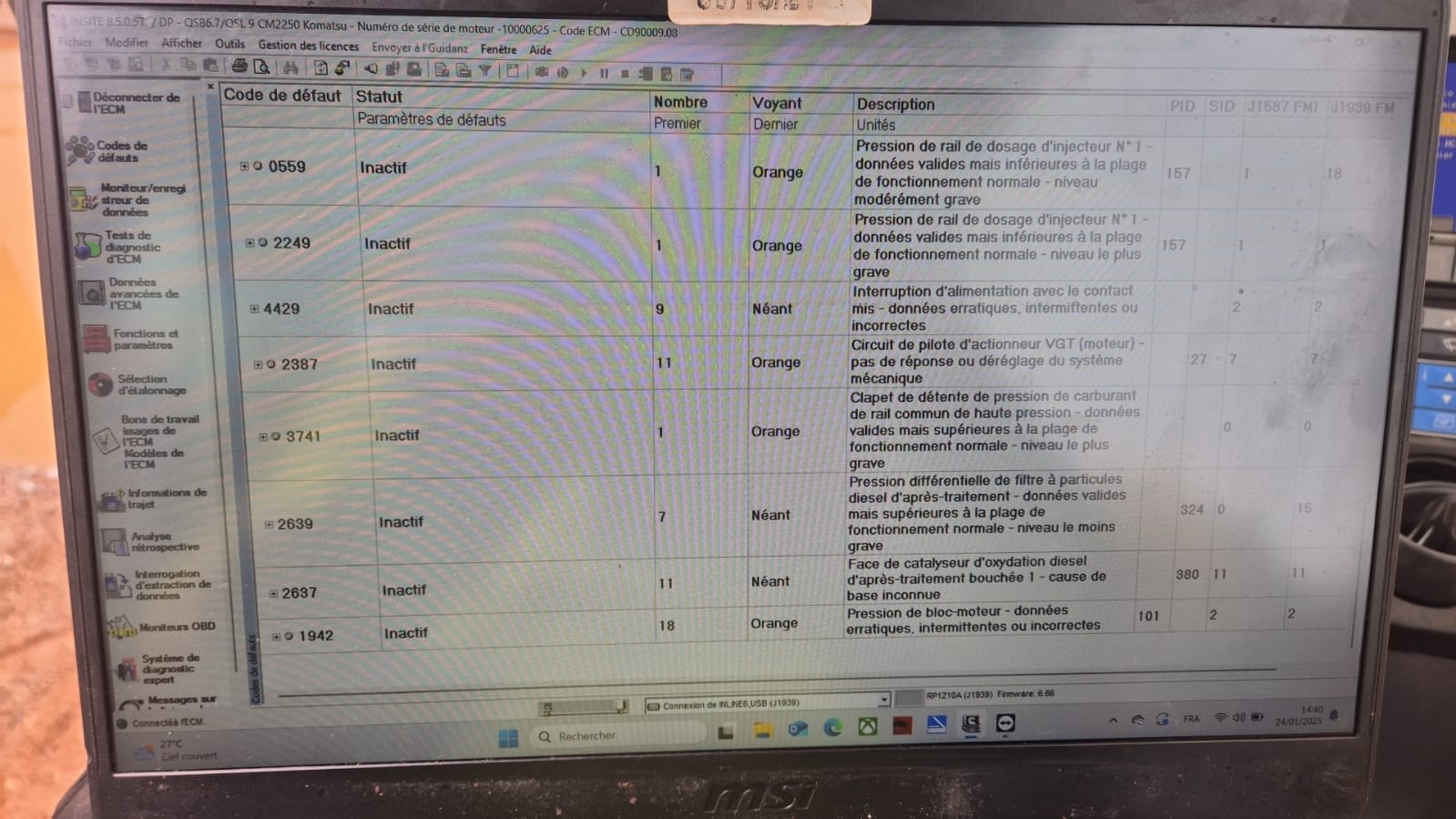

To correct PC240-LC10 regeneration problems, we use Calterm, an advanced tool for complete management of machine parameters. This software gives access to all the functions of the CM2250 ECU, allowing unrestricted intervention.

Process steps

- Precise fault diagnosis

- With Calterm, we analyze active fault codes and identify restrictions imposed by the emission control system.

- Complete reprogramming

- Elimination of DPF, SCR and NOx sensor cycles.

- Modification of ECU parameters to optimize the engine without limitations.

- Neutralization of physical components

- Drain the DPF to remove obstructions and avoid future regeneration cycles.

- Disconnect unnecessary sensors to ensure smooth operation without alarms.

- Final validation

- Rigorous testing ensures that your excavator operates at full capacity, without malfunctions or alerts.

Why treat the PC240-LC10 regeneration problem?

Interventions on anti-pollution devices offer immediate benefits for your Komatsu :

- Total elimination of alerts: Faults stored in the ECU disappear, ensuring uninterrupted operation.

- Maximum performance restored: the SAA6D engine delivers its full power, without the restrictions imposed by the CM2250 ECU.

- Lower maintenance costs: By eliminating regeneration cycles and neutralizing costly components, your costs are significantly reduced.

- Simplified maintenance: The engine is free of complex systems, making it easier to maintain.

- Increased reliability: DPF and SCR failures become non-existent, ensuring that the machine is always ready for use.

Call on Adblue-services.com to solve your regeneration problems

At Adblue-services.com, we specialize in optimizing the performance of machines like the Komatsu PC240-LC10. Thanks to our in-depth expertise and the use of advanced tools such as Calterm, we offer tailor-made interventions to eliminate regeneration-related problems once and for all. Our technicians, trained in the specifics of Cummins engines and CM2250 ECUs, guarantee reliable, long-lasting results.

You can find out more about our work in the following resources:

- Take a look at our work on Cummins engines to discover our specific services.

- Explore our achievements on Komatsu machines to see solutions for other models.

- Learn more about Cummins engines and our areas of expertise.

Contact us today to restore the performance of your Komatsu PC240-LC10 and eliminate regeneration constraints for good. With Adblue-services.com, transform your machine into a reliable, high-performance work tool.