Troubleshooting Adblue on Cat 963K Chain Loader Fault E1389

Machine, computer and motor

Troubleshooting the adblue system on a Cat 963K equipped with a C7.1 engine and an adem 5 engine ECU restored full use of the machine, which had been stuck in inducement severity high mode.

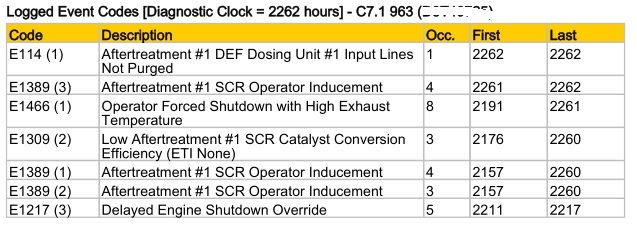

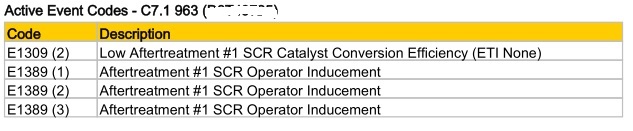

Description of present defects

E114: Aftertreatment #1 DEF Dosing Unit #1 Input Lines Not Purged

- This code means that there is a problem with the inlet lines to the DEF (Diesel Exhaust Fluid) dosing unit for the aftertreatment system. It seems that the inlet lines have not been properly purged.

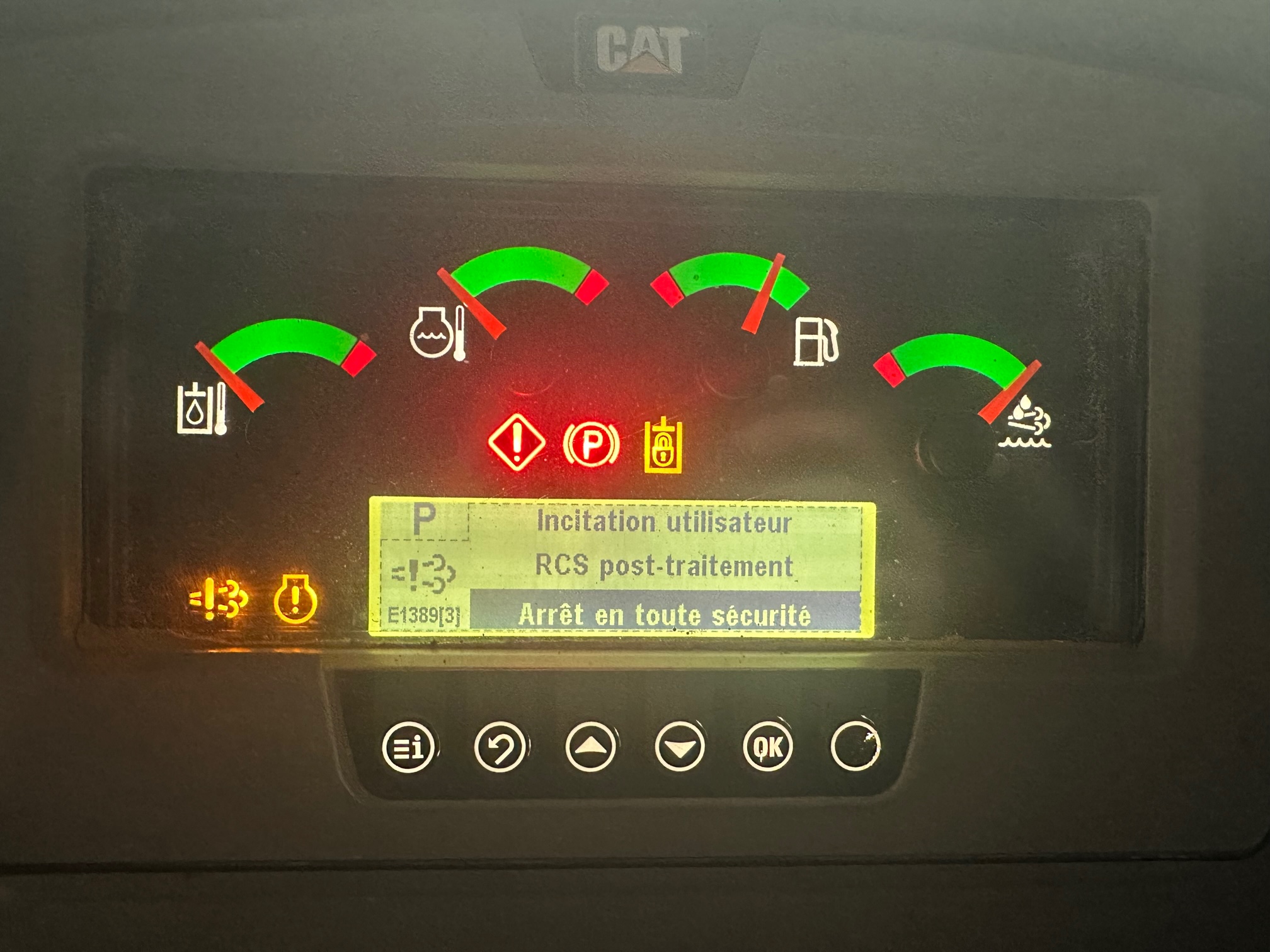

E1389: Aftertreatment #1 SCR Operator Inducement

- These codes indicate that the machine is restricted for the operator. The downgraded mode is therefore effective.

- E1466 : Operator Forced Shutdown with High Exhaust Temperature

- This code means that a forced stop has been initiated by the operator due to high exhaust temperature. This could be due to overheating of the exhaust system.

- E1309: Low Aftertreatment #1 SCR Catalyst Conversion Efficiency (ETI None)

- This code indicates low conversion efficiency of the SCR catalyst in the aftertreatment system.

- E1217: Delayed Engine Shutdown Override

- This code means that there has been a delay or overshoot in stopping the motor.

The problems that arise from these defects?

When post-processing faults are present with code E1389, we first have a downgraded mode with restricted engine power and torque, preventing any maneuvering with the machine. The faulty Adblue (SCR) system can no longer control pollutant emissions. Values are below the minimum threshold, even though many sensors have been changed.

The ultimate solution: Permanently deactivating defects

Complete programming of the motor management system helps avoid future problems. Updating the software not only resolves faults and eliminates degraded mode, but also guarantees efficient Adblue troubleshooting on Cat 963K. The operation takes an average of 2 to 3 hours, with a 99% success rate. It is not mandatory for parts connected to the anti-pollution system to be functional, as they will be deactivated. Please note, however, that machines must comply with a specific emission standard (Tier 4F here), and it is not permitted to remove a device if the machine is not intended for export. We are not responsible for any use that may be made of them.

Operations possible on the entire Caterpillar range

Our expertise enables us to work on all Cat machines, including all engines and ECUs. You can find an overview and feasibility of CAT machines on our explanatory page, as well as all our previous operations here.