Metso problem: Cat C13

Metso crusher and known Adblue problems: Caterpillar C13 engine

Just like road vehicles, construction and mining machinery, crushers can also be subject to adblue system failures. We've come across an adblue problem on a Metso, involving the EGR valve on the one hand, and the SCR (Adblue) system on the other.

What solutions for your Metso crusher following a recurring adblue problem?

The first and most obvious option is to replace any parts that appear to be faulty after running a diagnostics test. Of course, the cost of parts and labour is often high, and there's sometimes no guarantee that another part linked to the aftertreatment system will fail and immobilize your machine again. But this is the most logical way to proceed: by calling your dealer.

The second solution is to call on our services: our expertise in the field of electronic management of gas aftertreatment systems is well proven. We can troubleshoot your machine within 4 hours when we visit your site.

What are the recurring faults on Metso Lokotrack LT116 with CAT C13 engine?

Of course, faults related to the anti-pollution system

Particulate filter: When the machine is not used at full power, or when certain sensors fail (e.g. FAP pressure differential sensor), the vehicle or machine is unable to regenerate. As a result, the FAP becomes clogged over time and the machine's capacity is reduced.

The EGR valve: Recycling exhaust gases to burn them a second time has never been the best solution, and is rather anti-mechanical. Scale builds up in the intake and in the EGR valve, which no longer opens and closes properly. This often results in engine malfunction, with limited torque and pusisance.

The AdBlue system: The DEF (Diesel Exhaust Fluid) or adblue liquid gas aftertreatment system is not always optimal, and many components are involved in its operation. Pump, injector, Nox sensor, level gauge, adblue quality management, reduction catalyst (SCR)... all these electronically-managed elements are linked, and when one fails, the machine goes into power reduction mode, and for some vehicles into LIMP Mode (creep mode), making it impossible to exceed a certain speed (generally 20kmh).

What are the benefits of our programming solution for all these elements?

- Torque and power limits deactivated

- No DTC indicator on dash

- No need to refill the adblue tank (zero consumption)

- No need to regenerate the FAP (it can be emptied)

- EGR valve condensation possible

- All SCR-related sensors can be disconnected

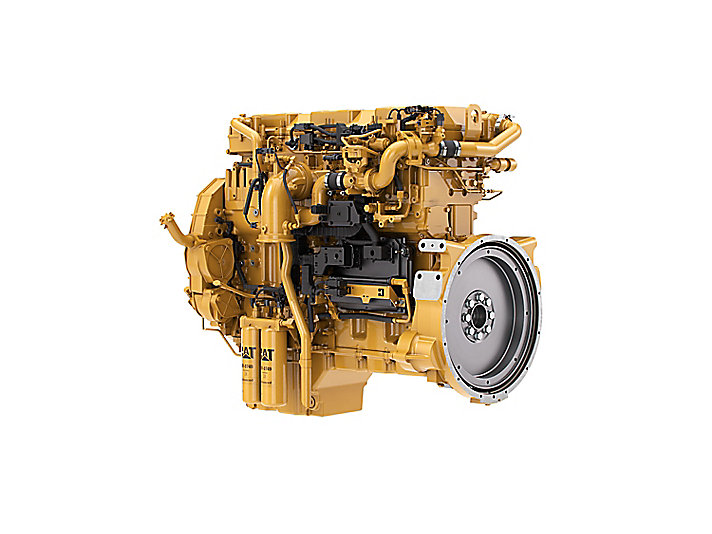

CAT C13 engine powering the Metso Lokotrack LT116

Equipped with an EGR valve, DPFS and SCR system, it develops 310 kW or 415 hp. Generally equipped with an ADEM 5 or ADEM 6 engine management ECU, we can intervene within the ECU and modify the entire parameterization and operation of ancillary components. It's also possible to improve efficiency.

We hope our article has helped you in your search. If you have any questions, please do not hesitate to contact us. You can also consult more information on Caterpillar CAT vehicles , All models included