Atlas Copco regeneration problem

Faults present : Regeneration system not possible

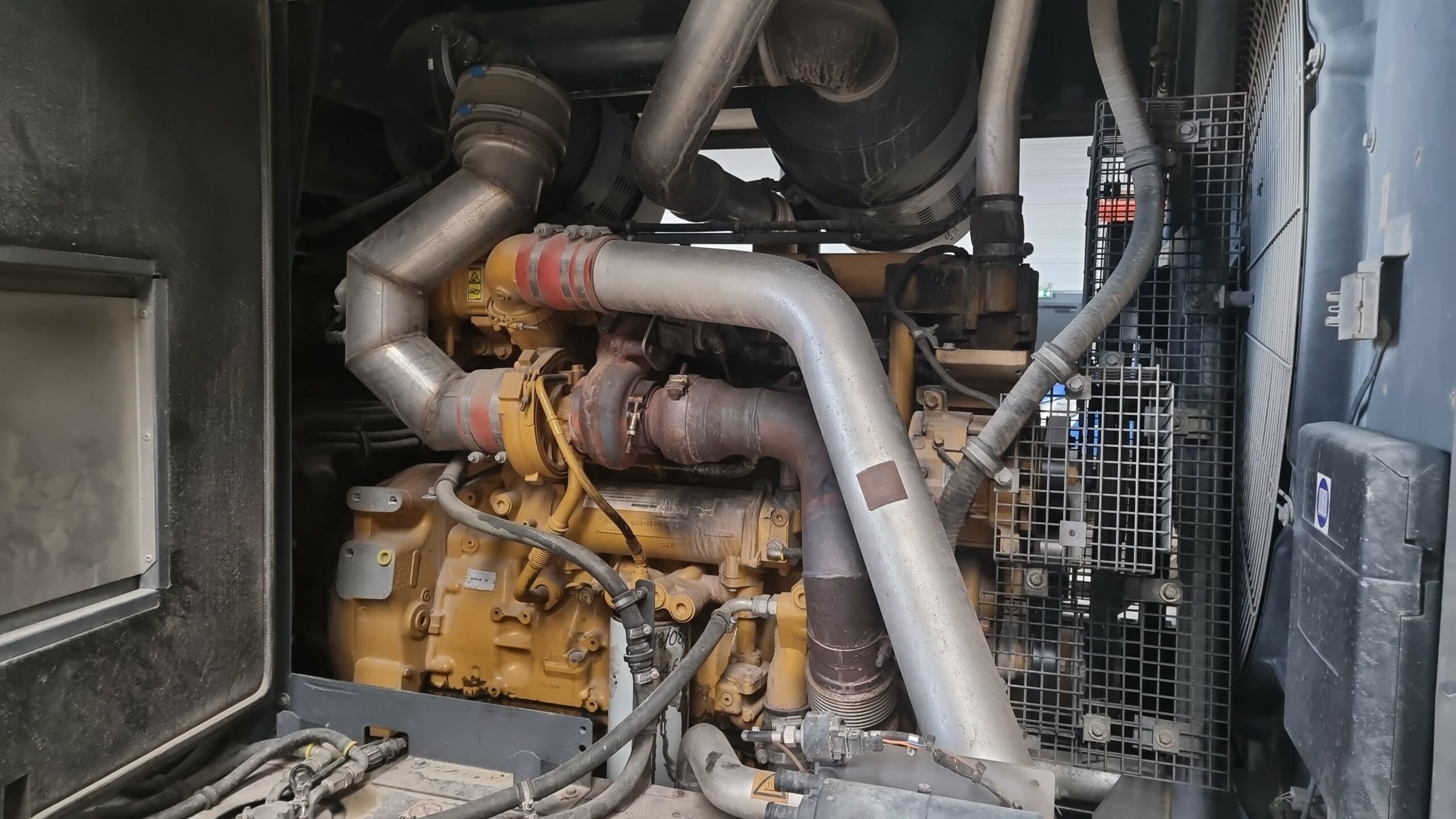

Following a problem with the regeneration of the particulate filter on an Atlas Copco compressor fitted with a Caterpillar engine, we had to find a solution to get the machine up and running again. In fact, the consequent drop in rpm due to the loss of power during regeneration attempts was endangering the worksite. When used with a drilling machine, there is a risk of internal landslides if the pressure required to lift the sand is not sufficient.

Explanation of FAP faults on Atlas Copco CAT C13

The ARD (Auto-Regeneration Device) head is used to regenerate diesel particulate filters (DPF) on Caterpillar engines. It burns off the soot particles accumulated in the DPF, maintaining its efficiency and avoiding expensive replacement costs. This regeneration is usually carried out automatically when the engine is operated at high loads.

The ARD head uses the heat generated by the engine to regenerate the diesel particulate filter (DPF). When soot particles accumulate in the DPF, the ARD head raises the engine temperature by increasing the combustion rate, thereby burning off the particles. This is usually achieved by increasing the proportion of air in the fuel-air mixture, thereby raising the combustion temperature. Regeneration can also be initiated manually by the operator if required. It is important to note that regeneration cannot take place if the engine is below a certain temperature, or if the soot level is too high.

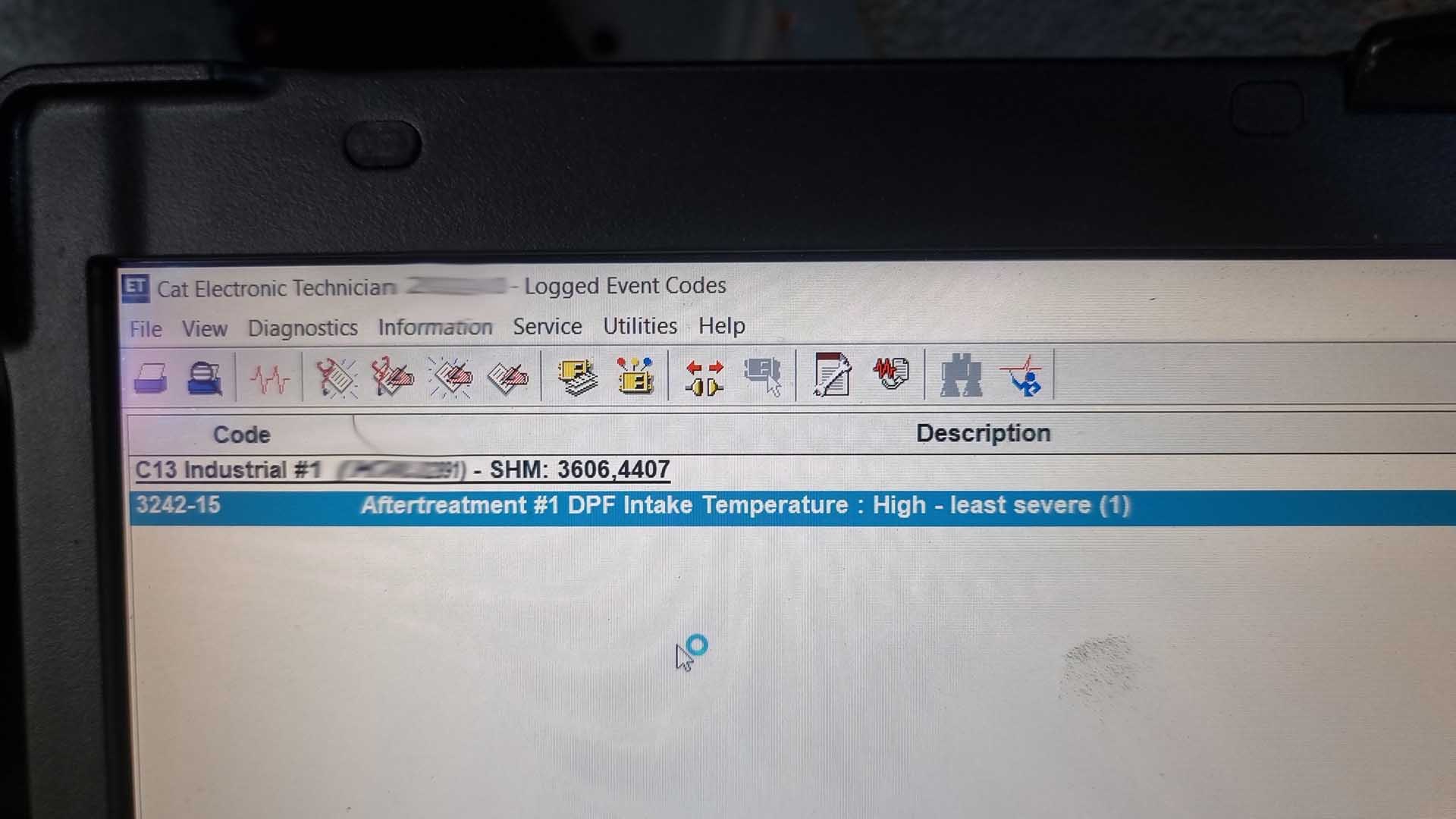

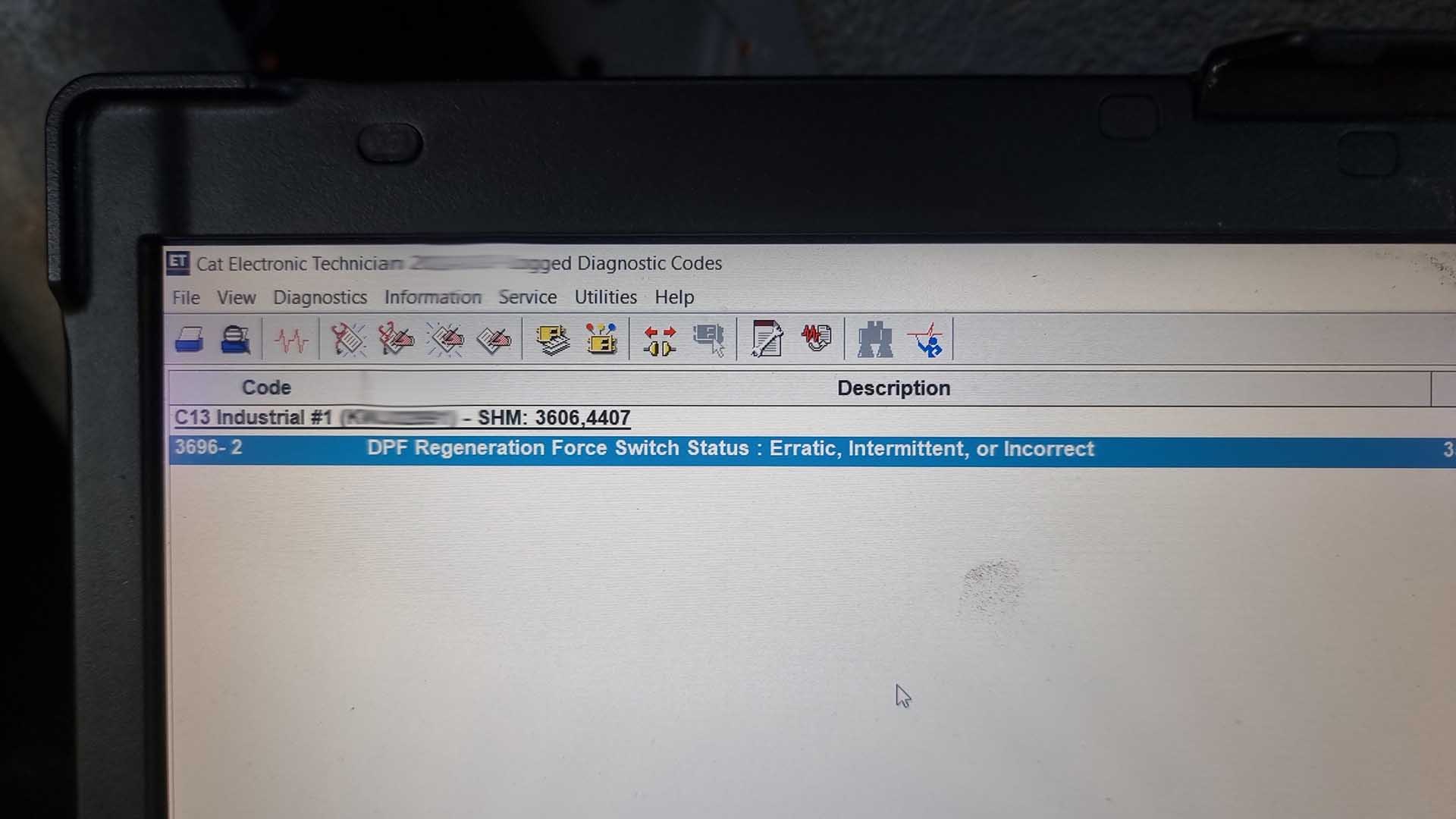

Faults 3696-2 and 3242-15 indicate problems with diesel particulate filter (DPF) regeneration and DPF inlet temperature.

- Fault 3696-2 indicates that the DPF regeneration force switch is experiencing problems, such as erratic, intermittent or incorrect response. This may be due to an electrical problem with the switch itself, or a communication problem with the engine control module (ECM). It is important to check the wiring and connectors associated with the switch to ensure that they are not damaged or incorrectly connected.

- Fault 3242-15 indicates that the DPF inlet temperature is too high. This can be caused by a number of factors, such as a fault in the DPF cooling system, a blockage in the air intake system, or a problem with the DPF inlet temperature control. It's important to check the components linked to the cooling and air intake systems to make sure they're working properly and that they're not clogged. It is also important to check the DPF inlet temperature control parameters to ensure that they are correct.

Solutions to regeneration problems

ECM firmware correction involves updating the ECM software to solve existing problems or improve motor performance. This can be done by using a specialized programming tool to download the new software to the ECM.

With regard to the inhibition of the ARD head's automatic regeneration function, this can be resolved by correcting the ECM programming parameters which control automatic regeneration. Factory settings can be reset, or adjusted to suit specific vehicle requirements, to remove the need for the filtration system.

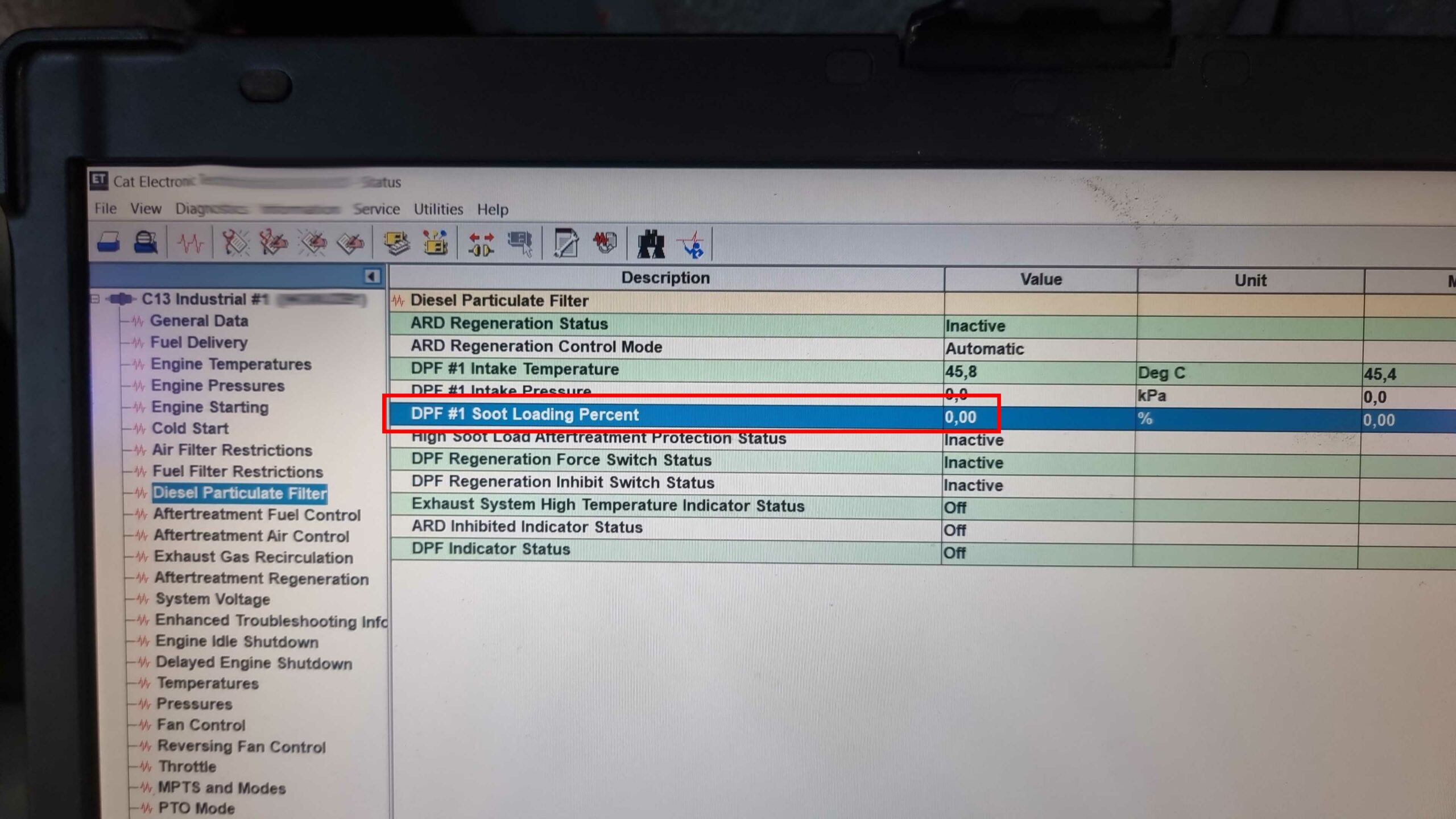

Following this operation, the particulate filter itself can be dismantled and emptied. The ARD head (with its electronic control) can be disconnected permanently. Restart the engine with the ARD connector disconnected, and you'll see that the soot level has dropped to 0%, and that regeneration will never be necessary again.

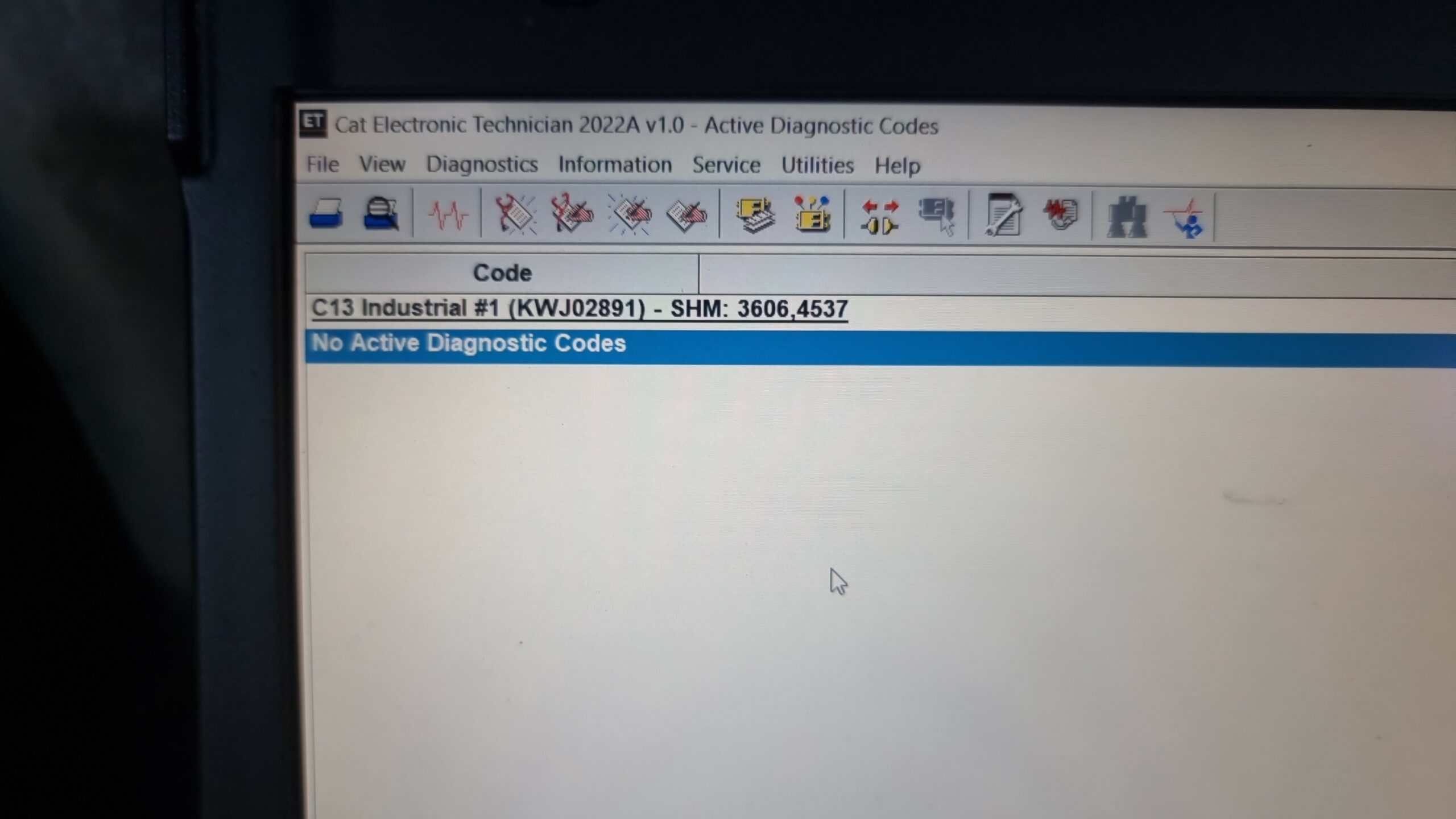

Passage to the suitcase and post-programming fault checking

As you can see, after rebooting the machine and installing a new software version, the faults have completely disappeared.