Stop Komptech Nemus 2700 degraded mode

Description of the problem and defects encountered

Prior to our intervention on this vehicle, various faults relating to the adblue system were active. Indeed, the degraded mode on Komptech Nemus 2700 prevents correct operation. This screening machine is designed to work at load engine speed. When the limp mode is activated due to a fault in the post-processing system, it becomes impossible to use the machine.

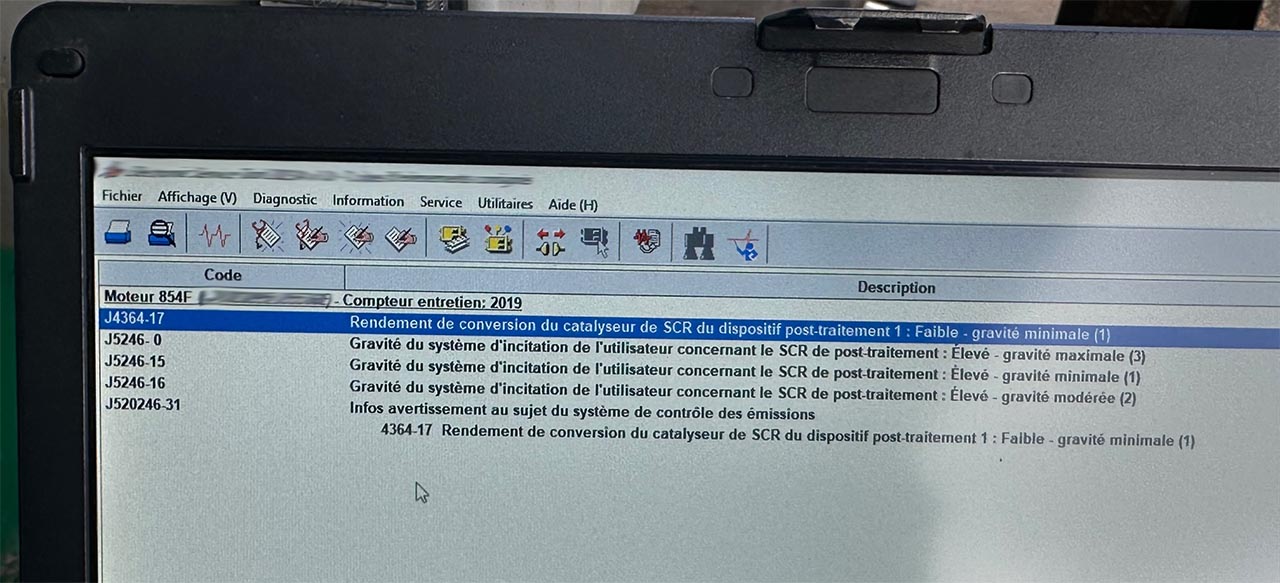

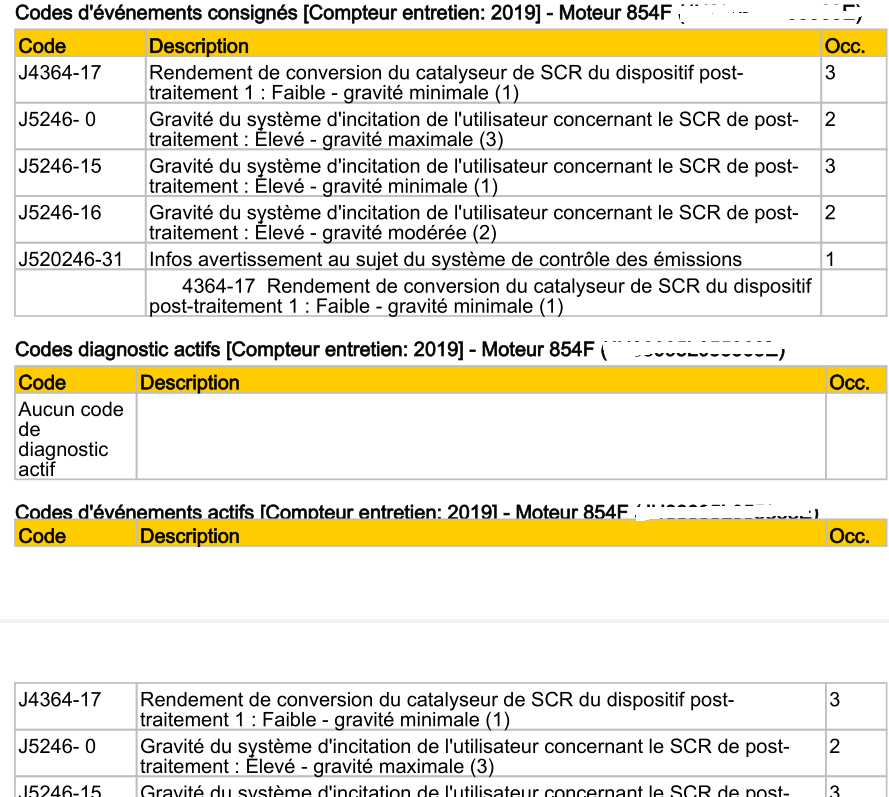

After interrogating the engine control unit, which allows the Perkins 854F engine to operate, we observed the following problematic faults:

Intervention on the Komptech Nemus 2700 machine was necessary because of several faults detected by the emission control system. These faults were identified by specific codes, each indicating the severity of the problem. Among the problems detected was the conversion efficiency of the SCR catalyst. Post-treatment device 1 was rated as weak, with minimal severity. In addition, other codes indicated high and moderate severity in the user incentive system for the aftertreatment SCR.

To put it simply, this is what we call 'derate' in our technician's language, or degraded mode. The only solution would have been to replace the entire exhaust system, at a cost of around €10,000.

Our final troubleshooting solution for Komptech Nemus

The ultimate troubleshooting solution is as follows: Inhibit the post-processing system by programming the Bosch module. The post-processing elements must be calibrated and reset using a special diagnostic tool. The Bosch EDC17C49 module is flashed directly using the bench method, to recover and save the vehicle's original configuration.

To remedy these problems, the intervention involved updating the machine's program. This update was carried out by means of a flash program, which replaced the old version of the program with a new one. This new version of the program was specially designed to correct the faults detected and improve the machine's performance.

The aim when flashing the new version is to do away with the Diesel Oxidation Catalyst/SCR Aftertreatment Configuration.

No more defects after the operation

As agreed, our software update operation has restored full machine performance. It should be noted that this program update was carried out in response to warnings from the emission control system, with the aim of guaranteeing the correct operation of the post-treatment device and ensuring long-lasting, trouble-free operation of the screen.

Operations possible on the entire Komptech range

Our expertise enables us to work on all Cat machines, including all engines and ECUs. You can find a summary and the feasibility of CAT machines on our our explanatory page as well as all our previous operations here on Komptech