Removing adblue faults on CAT 966M

Remove adblue from Caterpillar 966M permanently

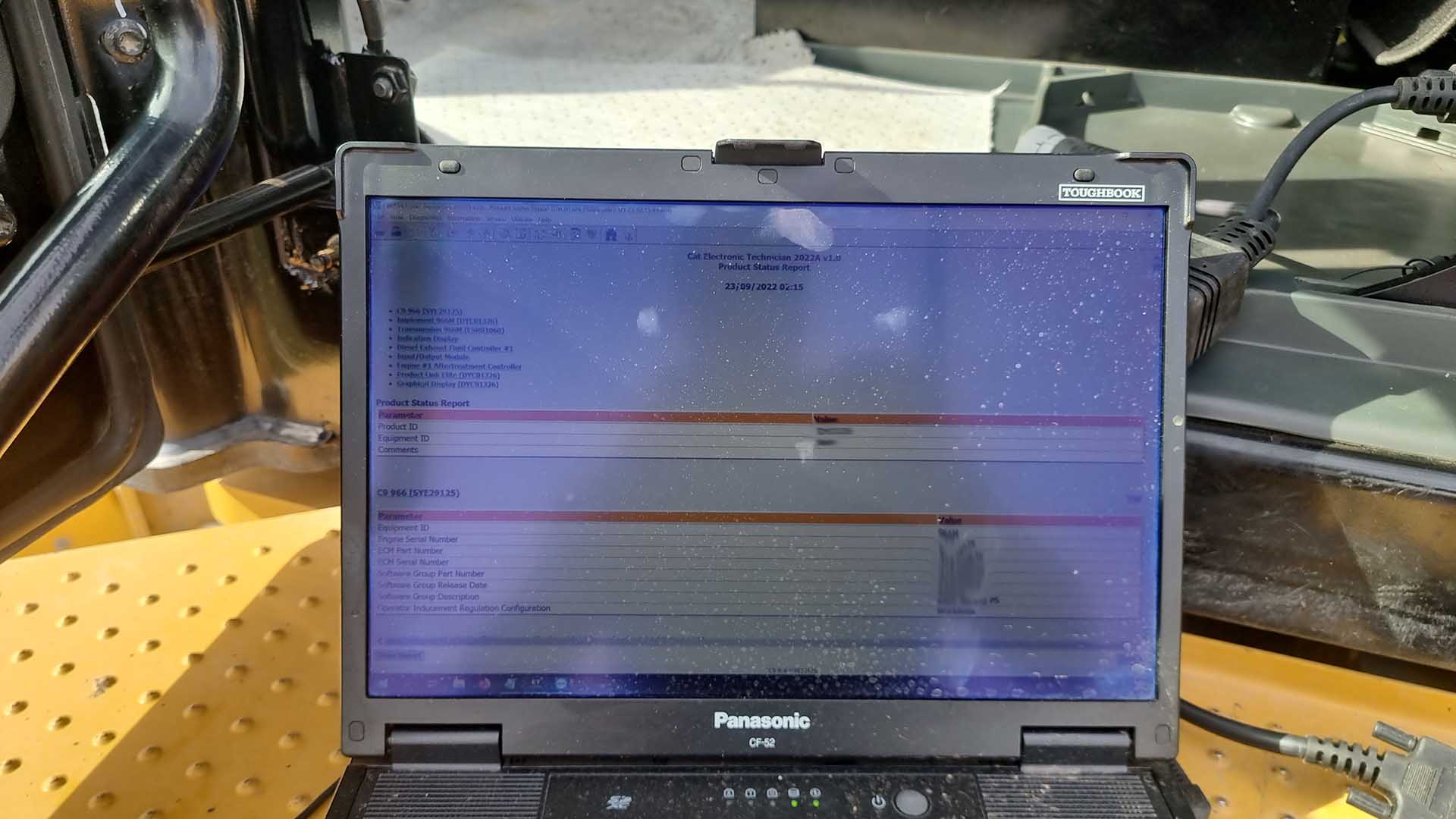

CAT 966M loaders are equipped with CAT C9.3 engines operating to Tier 4F emission standards. Until 2020, they are generally designed with ADEM V engine ECUs. We can intervene to deactivate the adblue system present on these machines, so that the warning lights on the dashboard disappear forever.

Here are some of the possible causes of a failing adblue system on a loader equipped with the 2019 CAT C9.3 engine that complies with Tier 4F standards:

- Adblue pump failure: the adblue pump is responsible for injecting adblue fluid into the exhaust system. If it fails, the adblue system will not function properly. DTC present on the dashboard, usually with level II severity (reduced engine performance).

- Adblue injector failure: the adblue injector is responsible for injecting adblue liquid into the exhaust stream. If the injector fails, the adblue system will not function properly.

- Adblue fluid level too low: It is important to ensure that the adblue fluid level is correctly filled. If the level is too low, the adblue system will not work properly. It may also be a dipstick problem.

- Electrical problem: there could be an electrical problem preventing the adblue system from working properly. This could be caused by a battery failure, a blown fuse, or the rarer but familiar problem of an electrical connection.

Limp mode on CAT 966M

The emissions-related limp mode can be activated when the engine detects an anomaly in the emissions management system. This may be caused by a sensor failure, a catalytic converter problem or any other problem that prevents the engine from operating optimally.

Limp mode can also be activated when the engine detects a problem with the diesel particulate filter (DPF). The DPF is an essential part of the emissions management system, trapping soot particles and other contaminants in the exhaust gases. If the DPF is clogged or damaged, the engine can go into limp mode to protect the engine and the emissions management system.

When the particle filter is clogged, and depending on the percentage of soot present inside, different levels of severity are again activated. Level I, low severity, requires user regeneration. Level II puts the engine into performance-restriction mode (reduced torque and engine power), inducing it to use only a certain percentage of power. (The suitcase indicates the rate of restriction). Level III generally requires the physical intervention of a technician, as well as mandatory parts changes. In 95% of cases, a clogged particulate filter cannot be regenerated, and even if the ash and soot levels are reset, only replacing the DPF will enable the vehicle to run normally again.

With our program it is the final Remove adblue on Caterpillar 966M

Following our reprogramming, the faults will be permanently eliminated, but in the case of a totally clogged particulate filter, it will be compulsory to remove it mechanically. The Adblue ECU can be disconnected without displaying any DTC code on the dashboard. This will optimize your machine's performance and prevent breakdowns.

Operations possible on the entire Caterpillar range

Our expertise enables us to work on all Cat machines, including all engines and ECUs. You can find an overview and feasibility of CAT machines on our explanatory page, as well as all our previous operations here.