Adblue fault on MH3024 Excavator - Post-treatment problem

Description of the machine in question and type of engine involved

Intervention to resolve an exhaust gas after-treatment problem (Adblue fault on MH3024 excavator), equipped with Caterpillar C7.1 engine, FAP and Adblue system. It meets Tier 4F standards. The machine is from 2018

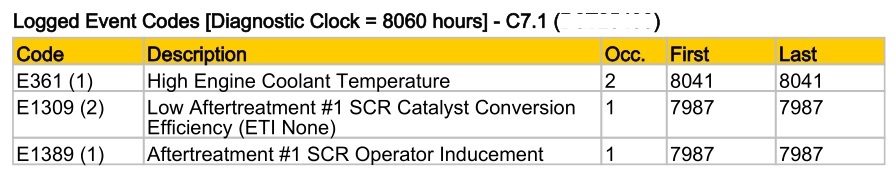

Adblue defects present on the MH3024 Caterpillar excavator :

E1309 - Low Aftertreatment #1 SCR Catalyst Conversion Efficiency

This code indicates that the conversion efficiency of the SCR (Selective Catalytic Reduction) catalyst in the aftertreatment system is too low. This may be due to a fault in the emission control system, urea injector, temperature sensor, etc. Low conversion efficiency. Parts to be replaced may include: adblue injector, temperature sensor, NOx sensors.

Code E1389 - Aftertreatment #1 SCR Operator Inducement:

Degraded mode, also known as degraded mode or safety mode, is a state in which a vehicle or piece of equipment reduces its normal performance of your MH3024 scoop to prevent more serious damage or critical system failures. When a vehicle detects a potentially dangerous problem or failure in one of its systems, it can activate the degraded mode to limit the risks and enable the driver or operator to return the vehicle safely to a repair shop.

In the context of your error code E1389 - Aftertreatment #1 SCR Operator Inducement, it indicates that the operator has had to intervene to resolve a problem with the SCR (Selective Catalytic Reduction) emissions reduction system. In this case, the vehicle may have detected a drop in efficiency in the emissions reduction process, which could potentially increase pollutant levels.

Consequences of machine faults

Prior to our intervention, the customer changed various parts of the anti-pollution system. Injector and pump changed. The problem caused by the rather large invoice is still present. Caterpillar erased the faults in the engine ECU's memory, but after a few hours' work on the excavator, they reappeared.

The vehicle's power is blocked and it can only move at reduced speed. Moreover, lifting loads becomes totally impossible due to the lack of engine power caused by the limp mode.

The final option: Deactivation of faults and AdBlue injection system

AdBlue parameters can be deactivated using a specially designed program. This program deactivates AdBlue-related functions, such as injection of emission-reducing fluid and regeneration of the diesel particulate filter (DPF).

To do this, you need to access the vehicle's ECU parameters and modify the configurations. This is done using a specific diagnostic tool to access ECU parameters. This method maintains machine performance while avoiding the additional cost of AdBlue. It also saves on maintenance and repair costs by avoiding problems with the AdBlue system.

It is crucial to ensure that the process is carried out by qualified professionals to avoid damaging the equipment or encountering performance problems. Correct execution of the process can guarantee the machine's smooth operation on site, and avoid penalties due to delays.

Operations possible on the entire Caterpillar range

Our expertise enables us to work on all Cat machines, including all engines and ECUs. You can find an overview and feasibility of CAT machines on our explanatory page, as well as all our previous operations here.