Problème AdBlue sur Balayeuse Bucher Municipal Optifant

Introduction : Les balayeuses Bucher Municipal Optifant, équipées du moteur JCB 444, sont essentielles pour le nettoyage urbain. Cependant, comme tout équipement sophistiqué, elles peuvent rencontrer des problèmes, notamment liés au système AdBlue. Lorsque des défauts surviennent, ils peuvent gravement affecter les performances de la machine, allant de la réduction de puissance à la mise en mode dégradé. Cet article vous guidera à travers les étapes de diagnostic, de reprogrammation et de résolution des problèmes AdBlue sur ces balayeuses, en mettant en lumière les pannes courantes et les méthodes d’intervention efficaces.

Caractéristiques du Calculateur Delphi DCM3.3 et du DCU Bosch DCU17CV51 : Les balayeuses Bucher Municipal Optifant de 2019 utilisent deux calculateurs principaux : le Delphi DCM3.3 pour le moteur et le Bosch DCU17CV51 pour la gestion du système AdBlue. Le calculateur Delphi DCM3.3 est responsable de la gestion des performances du moteur, de l’injection de carburant et de la conformité aux normes d’émission. Il utilise des capteurs pour surveiller diverses fonctions du moteur et ajuste les paramètres en temps réel pour optimiser la performance et l’efficacité. De l’autre côté, le Bosch DCU17CV51 gère spécifiquement le système AdBlue, contrôlant l’injection de l’additif dans le flux d’échappement pour réduire les émissions d’oxyde d’azote. Ces calculateurs travaillent ensemble pour assurer une performance optimale.

Procédure de Reprogrammation du Calculateur et du DCU :

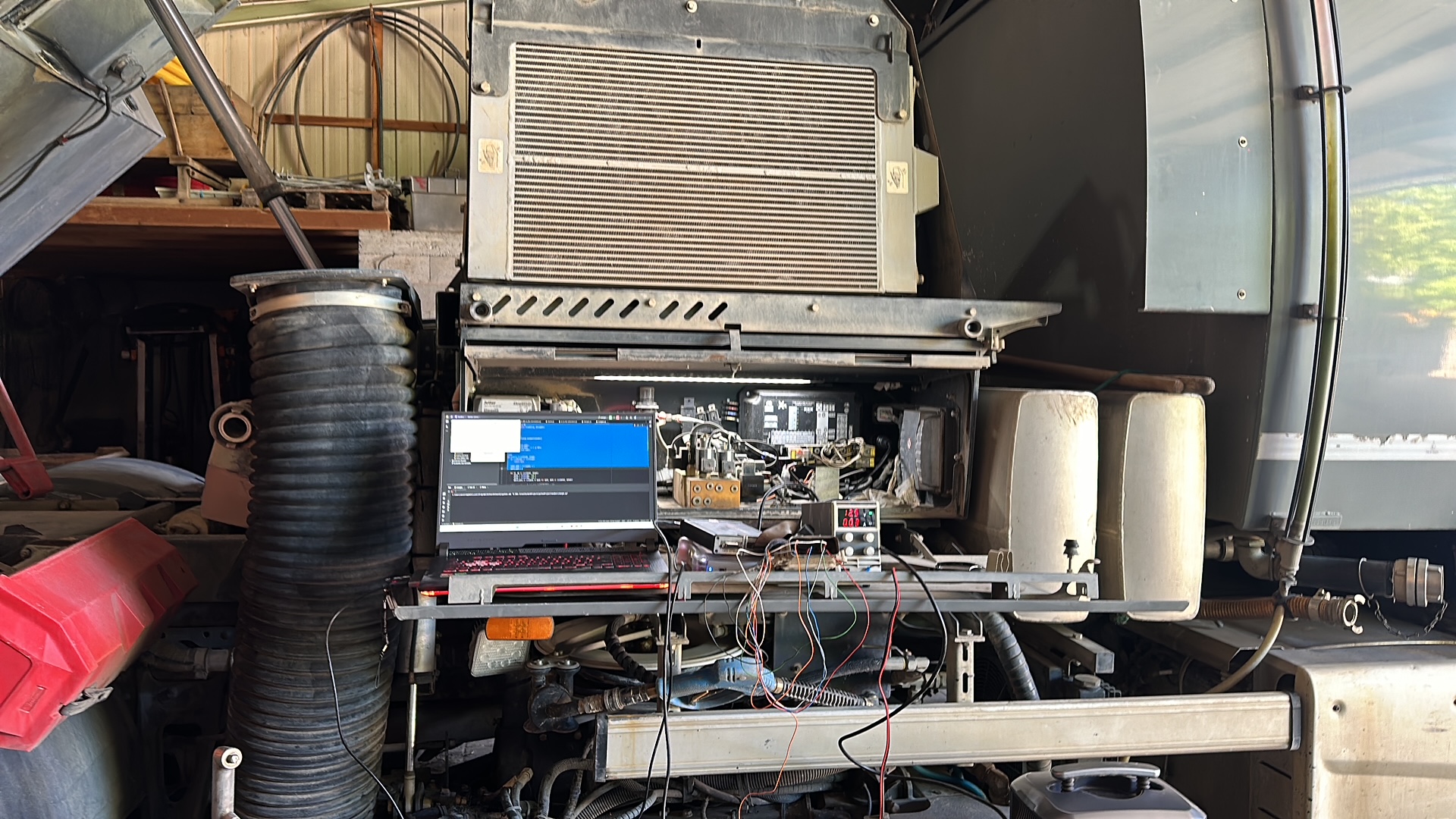

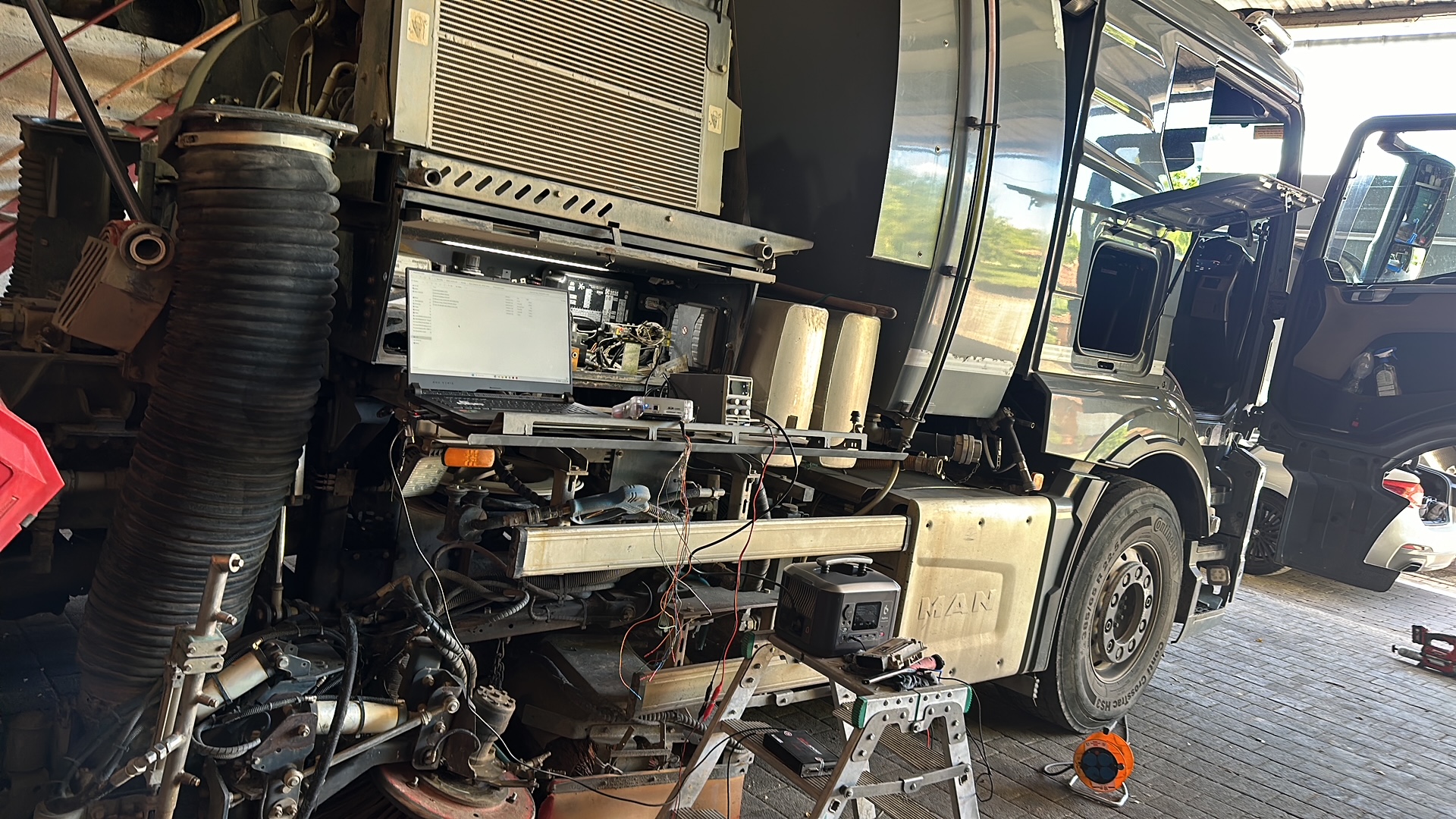

Étape 1 : Connexion et Lecture des Données : La première étape de la reprogrammation consiste à connecter les outils de diagnostic spécifiques aux calculateurs. Pour l’ECU Delphi DCM3.3, la connexion se fait via l’OBD (On-Board Diagnostics), un port standardisé permettant l’accès aux données du véhicule. Une fois connecté, l’outil de diagnostic lit les codes défauts présents et les données de cartographie du moteur. Pour le DCU Bosch DCU17CV51, la lecture se fait par méthode bench, en se connectant directement aux pins du calculateur et en alimentant en externe par une alimentation stabilisée. Cette méthode permet un accès direct et complet à la mémoire flash du calculateur, essentiel pour une reprogrammation précise. La lecture initiale des données et des codes défauts permet d’identifier les problèmes exacts affectant le système AdBlue et de préparer le terrain pour l’élaboration d’un nouveau programme de fonctionnement.

Étape 2 : Élaboration du Nouveau Programme : Après avoir identifié les défauts et extrait les données nécessaires, l’étape suivante consiste à élaborer un nouveau programme pour le véhicule. Ce processus implique l’analyse des données de cartographie du moteur et de la mémoire du microcontrôleur pour comprendre les ajustements nécessaires. Les techniciens utilisent des logiciels spécialisés pour modifier les paramètres de fonctionnement du moteur et du système AdBlue, visant à corriger les défauts identifiés et à optimiser les performances. Le nouveau programme est conçu pour améliorer la gestion des émissions, augmenter l’efficacité du moteur sur le long terme et ainsi stopper tous les problèmes AdBlue sur balayeuse à moteur JCB.

Étape 3 : Flashage du Calculateur et du DCU : Le flashage, ou reprogrammation, est l’étape où le nouveau programme est écrit dans la mémoire des calculateurs. Pour l’ECU Delphi DCM3.3, cela se fait via l’OBD. Le logiciel de diagnostic charge le nouveau programme dans la mémoire flash de l’ECU, remplaçant l’ancienne cartographie. Pour le DCU Bosch DCU17CV51, la reprogrammation se fait par méthode bench, avec une connexion directe aux pins du calculateur et une alimentation stabilisée. Cette méthode garantit une écriture précise et sans interruption. Il est crucial de vérifier les bonnes connexions des alimentations, de la masse, des CAN et du voltage pour éviter tout dommage aux calculateurs. Une fois le flashage terminé, les systèmes sont redémarrés pour vérifier que le nouveau programme fonctionne correctement et que tous les codes défauts sont résolus.

Une fois cette vérification faite, nous passons à une inspection visuelle du tableau de bord pour garantir qu’il n’y a ni voyants d’alerte ni messages d’erreur. Enfin, effectuez un essai de fonctionnement avec le client pour vérifier le bon fonctionnement global de la machine. Cet essai permet de confirmer que les problèmes ont été résolus et que la balayeuse fonctionne de manière optimale, sans perte de puissance ni mode dégradé.

Pannes Courantes du Système AdBlue :

Liste des Pannes : Les pannes courantes du système AdBlue sur les balayeuses Bucher Municipal Optifant comprennent divers problèmes de capteurs, de pompes et de communication entre calculateurs. Par exemple, un capteur de niveau de fluide défectueux peut entraîner un voyant d’alerte et des messages d’erreur, rendant le système AdBlue inopérant et réduisant la puissance du moteur. Une pompe AdBlue en panne, quant à elle, empêche l’injection correcte de l’additif, ce qui peut augmenter les émissions et entraîner la mise en mode dégradé du véhicule. Un injecteur AdBlue bouché ou défectueux provoque une mauvaise atomisation de l’additif, réduisant l’efficacité du système SCR (Selective Catalytic Reduction). Des problèmes de chauffage du réservoir AdBlue, comme la cristallisation de l’additif, peuvent bloquer le système, nécessitant une intervention manuelle. Enfin, des défauts de communication entre l’ECU et le DCU peuvent désactiver le système AdBlue, entraînant une dégradation des performances du moteur.

Codes Défauts Communs et Leurs Impacts : Exemples :

SPN521011 FMI1 : Ce code défaut indique un problème de communication entre les modules du système AdBlue. Lorsqu’il apparaît, le moteur peut voir son couple réduit, entraînant une perte significative de puissance. Cette réduction de couple peut rendre la machine inutilisable pour certaines tâches, nécessitant une intervention immédiate pour éviter des arrêts prolongés. Le diagnostic de ce code nécessite des outils de diagnostic spécifiques pour vérifier les connexions et la communication entre les différents calculateurs.

SPN521010 FMI31 : Ce code défaut signale une erreur critique dans le système AdBlue, souvent liée à une panne de la pompe ou à un injecteur bouché. Le véhicule passe en mode dégradé pour protéger le moteur, ce qui limite ses performances et son utilisation. Une fois ce code détecté, il est crucial de vérifier et de remplacer les composants défectueux pour restaurer le fonctionnement normal du système AdBlue et du moteur.

SPN521003 FMI2 : Ce code indique une anomalie dans le système de dosage AdBlue. Les symptômes incluent des messages d’alerte sur le tableau de bord et une possible non-conformité aux normes d’émissions. Pour résoudre ce problème, il est nécessaire de vérifier l’injecteur AdBlue et la pompe pour s’assurer qu’ils fonctionnent correctement et qu’il n’y a pas de blocages ou de défaillances.

SPN521002 FMI2 : Ce code défaut est lié au système de chauffage du réservoir AdBlue. Lorsque le chauffage ne fonctionne pas correctement, l’AdBlue peut cristalliser, bloquant le système et réduisant l’efficacité du traitement des émissions. La résolution de ce problème implique souvent la vérification du système de chauffage et la dégivrage manuel du réservoir si nécessaire.

Notre savoir faire permet d’intervenir sur la totalité des machines à moteur JCB, tous moteurs et calculateurs confondus. Vous pouvez retrouver toutes nos opérations déjà réalisées ici.