Les chargeurs Volvo L70H sont connus pour leur fiabilité, mais le système AdBlue peut poser problème. Lorsque ce système tombe en panne, la machine perd en puissance. Pire encore, elle peut s’immobiliser, bloquant vos activités. Nous vous expliquons comment résoudre ces pannes.

Symptômes fréquents des pannes AdBlue sur Volvo L70H

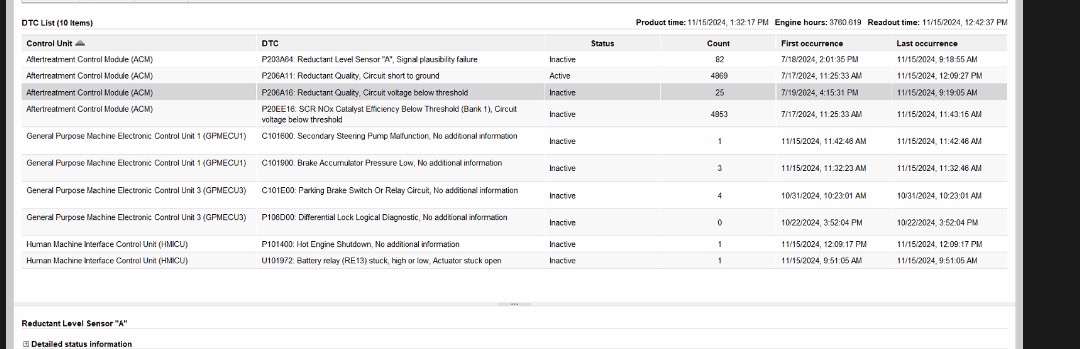

Lors de notre dernière intervention, cette Volvo L70H de 2018 affichait plusieurs signes de dysfonctionnement. Tout d’abord, un message d’alerte « Vérifier syst. SCR » apparaissait sur l’écran de contrôle, accompagné d’une réduction de puissance active qui limitait l’utilisation de la machine. De plus, plusieurs codes défauts (DTC) avaient été relevés dans le calculateur moteur, tels que :

-

P20A64 : Reductant Level Sensor « A », Signal plausibility failure

Ce code indique un problème au niveau du capteur de niveau d’AdBlue. Ce dernier envoie des informations incohérentes ou illogiques au calculateur moteur (ACM – Aftertreatment Control Module). Ce dysfonctionnement peut être causé par plusieurs facteurs, notamment un capteur défectueux, une connectique oxydée ou un câblage endommagé. Parfois, un mauvais calibrage du capteur ou une usure générale peut également être en cause. Ce défaut perturbe l’évaluation précise du niveau d’AdBlue dans le réservoir, ce qui peut déclencher des alertes ou même arrêter le système SCR.

-

P206A11 : Reductant Quality, Circuit short to ground

Ce code met en évidence un court-circuit dans le circuit du capteur de qualité d’AdBlue. Cela peut être dû à une isolation endommagée sur les câbles, des connecteurs en mauvais état ou des défauts internes au capteur lui-même. Une autre cause fréquente est l’utilisation d’un AdBlue de mauvaise qualité ou contaminé par des impuretés comme de l’eau ou des particules solides. Lorsque le calculateur détecte une mauvaise qualité d’AdBlue, il bloque le fonctionnement du système SCR pour protéger le moteur. Cela entraîne une réduction de puissance et empêche la machine de fonctionner normalement.

-

P20E016 : Reductant Quality Sensor Circuit, Voltage below threshold

Ce défaut signale une tension trop basse provenant du capteur de qualité d’AdBlue. Cela peut indiquer une alimentation insuffisante, souvent due à un problème de câblage ou à un connecteur défectueux. Dans certains cas, le capteur lui-même est en panne et ne peut plus fournir les données nécessaires au calculateur. Ce défaut empêche le système SCR de vérifier correctement la qualité de l’AdBlue, ce qui bloque les cycles de régénération et peut entraîner une réduction immédiate des performances de la machine.

Ces pannes empêchent souvent le fonctionnement optimal des Volvo L70H. Elles nécessitent une intervention rapide et précise pour éviter des coûts importants ou des arrêts prolongés.

Diagnostic panne SCR Volvo L70H – Une méthode rigoureuse

Nous avons appliqué un processus méthodique pour diagnostiquer les causes du problème. Dans un premier temps, nous avons utilisé un outil de diagnostic avancé pour lire et enregistrer tous les codes défauts présents dans le calculateur moteur. Ensuite, nous avons analysé les données collectées pour identifier les composants défaillants, notamment les capteurs SCR, les injecteurs et le circuit AdBlue.

Une fois les analyses terminées, nous avons validé le diagnostic en vérifiant les valeurs des capteurs et les paramètres du calculateur moteur. Il est apparu clairement que la machine souffrait d’un dysfonctionnement AdBlue Volvo lié à plusieurs défaillances combinées. Cette étape est essentielle, car elle permet de planifier l’intervention de manière précise et efficace.

Suppression AdBlue Volvo L70H – Étapes de l’intervention

Pour corriger les défauts constatés, nous avons procédé à une suppression AdBlue Volvo L70H en plusieurs étapes. Chaque phase de cette intervention est réalisée avec soin pour garantir un résultat optimal :

- Lecture et extraction des données constructeur : Nous avons récupéré les fichiers d’origine, également appelés « dumps », directement depuis le calculateur électronique de la machine. Cette opération est indispensable pour accéder aux paramètres du moteur et aux réglages du système SCR.

- Modification logicielle ciblée : Une fois les données collectées, nous avons désactivé les fonctions responsables des restrictions et des limitations causées par les défauts AdBlue. Ce travail de recalibrage est réalisé avec précision pour s’assurer que la machine fonctionne correctement.

- Flashage du calculateur : Nous avons ensuite injecté le programme modifié dans la mémoire du calculateur moteur. Cette étape permet de supprimer les défauts de manière définitive.

- Tests finaux sur site : Enfin, nous avons testé la machine en conditions réelles avec le client. Tous les codes défauts ont été effacés ou rendus inactifs, et la machine a retrouvé sa pleine puissance.

Ce processus garantit une réparation système SCR Volvo L70H fiable et durable, tout en éliminant les risques de nouvelles pannes liées à l’AdBlue.

Pannes courantes du système AdBlue sur Volvo L70H

Les chargeurs Volvo L70H sont souvent confrontés à des pannes similaires. Voici les problèmes les plus fréquents que nous rencontrons sur ces machines :

- Défaillance du capteur NOx : Lecture incohérente des données d’émissions ou capteur complètement hors service.

- Injecteur AdBlue obstrué : L’injection est insuffisante ou inexistante, ce qui bloque le fonctionnement du système SCR.

- Réchauffeur du réservoir AdBlue défectueux : En cas de températures basses, l’AdBlue cristallise et le système cesse de fonctionner.

- Blocage de la régénération SCR : La machine n’arrive pas à effectuer son cycle de régénération, ce qui entraîne une accumulation de particules.

- Problèmes liés à la qualité ou au niveau d’AdBlue : Souvent dus à des capteurs en panne ou mal calibrés.

Ces défauts AdBlue chargeur Volvo peuvent être évités ou corrigés grâce à un diagnostic et une réparation rapide.

Conclusion

Ces défauts sont courants sur les machines équipées de systèmes SCR et AdBlue. Ils résultent souvent de problèmes au niveau des capteurs, des câblages, des composants vieillissants ou encore de la cristallisation de l’AdBlue dans des conditions froides. Ces dysfonctionnements peuvent entraîner des immobilisations prolongées et des réparations coûteuses si aucune action rapide n’est prise.

Grâce à notre expertise et notre méthode de suppression AdBlue Volvo L70H, nous avons pu résoudre l’ensemble des problèmes rencontrés sur cette machine. La suppression des défauts SCR et AdBlue a permis de restaurer un fonctionnement optimal, tout en réduisant les coûts d’entretien et les risques de pannes futures. Cette intervention assure à la machine une fiabilité accrue et des performances durables.

Autre interventions réalisées sur Volvo CE

Vous pouvez consulter nos autres interventions réalisées sur machines Volvo CE.