Défaut AdBlue sur pelle Doosan DX300 : une source fréquente de panne

Le défaut AdBlue sur pelle Doosan DX300 est une panne fréquente qui affecte directement les performances et la productivité sur chantier. Équipées du moteur DL08P, ces machines rencontrent régulièrement des dysfonctionnements liés au système SCR, provoquant des baisses de puissance, une surconsommation d’AdBlue, et des arrêts d’activité intempestifs.

Pour résoudre durablement ces problèmes, il faut supprimer définitivement les codes défauts AdBlue enregistrés dans le calculateur moteur. Cette intervention élimine les limitations de puissance et met fin à la consommation inutile d’urée, garantissant un fonctionnement stable et sans contrainte.

La solution repose sur une reprogrammation ciblée du calculateur Bosch EDC17CV41, utilisé sur le moteur DL08P. En modifiant les paramètres internes liés à la gestion SCR, on restaure un comportement moteur optimal, sans défaut actif, ni perte de couple sur le terrain.

Diagnostic des défauts pour défaut AdBlue sur pelle Doosan (Bosch EDC17CV41)

Réaliser un diagnostic précis est essentiel avant toute intervention sur une pelle Doosan DX300 équipée du moteur DL08P et du calculateur Bosch EDC17CV41. Certains défauts persistent même après remplacement de pièces, poussant souvent à envisager la suppression complète du système AdBlue pour éviter les pannes répétées.

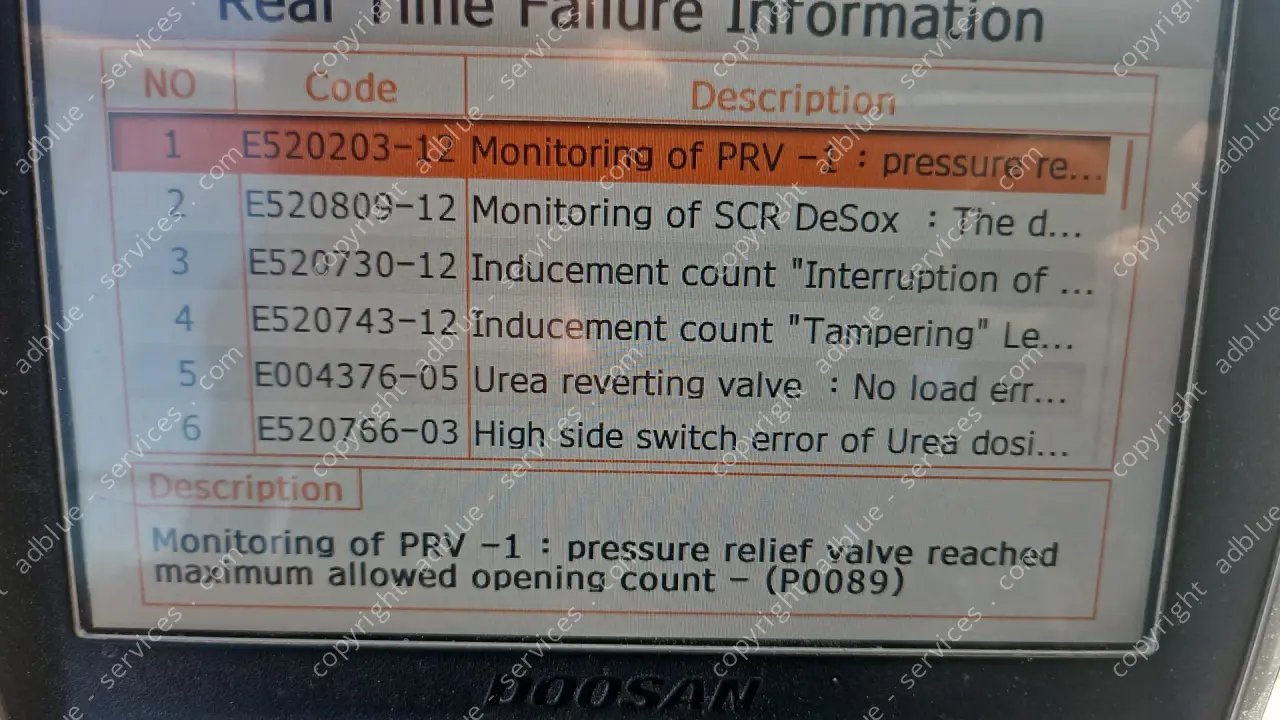

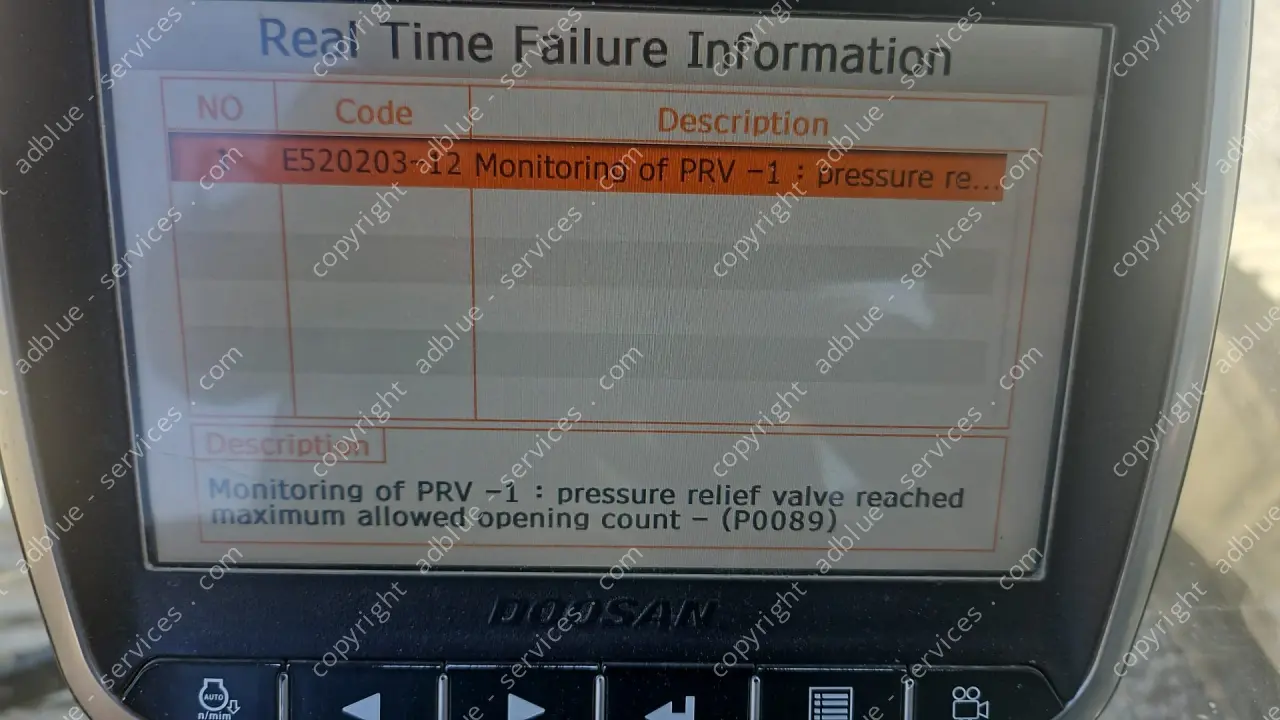

Voici les codes relevés en lien avec le système SCR :

E520809-12 – Monitoring of SCR DeSox : The deSOx temperature was not reached

Le SCR ne chauffe pas assez. Le capteur de température peut être défaillant. Le catalyseur peut perdre en efficacité.

E520730-12 – Inducement count « Interruption of DEF dosing » level exceeded

L’injection d’urée s’interrompt trop souvent. La pompe ou les conduites peuvent être obstruées. Le système passe en mode dégradé.

E520743-12 – Inducement count « Tampering » level exceeded

Le calculateur détecte une manipulation. Un capteur peut avoir été shunté ou débranché. Le système réduit la puissance.

E004376-05 – Urea reverting valve : No load error

La vanne de retour d’urée ne répond pas. Problème électrique ou mécanique probable.

E520766-03 – High side switch error of Urea dosing

Le circuit de commande haute tension du module d’injection présente un défaut. Court-circuit ou panne interne possible.

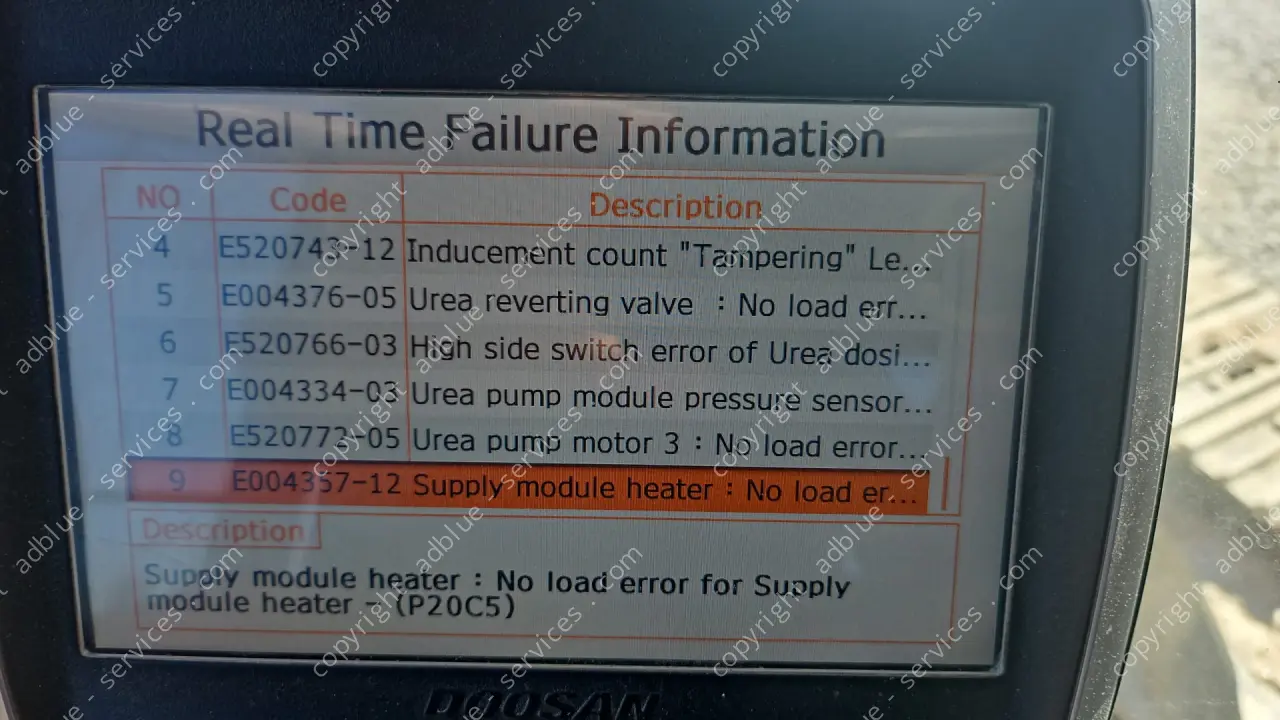

E004334-03 – Urea pump module pressure sensor error

Le capteur de pression donne une lecture incohérente. Il peut être endommagé ou mal calibré.

E520772-05 – Urea pump motor 3 : No load error

La pompe tourne à vide. Le moteur peut être bloqué ou grillé. L’injection ne se fait plus.

E004357-12 – Supply module heater : No load error (P20C5)

Le chauffage du module ne fonctionne pas. Résistance coupée ou circuit ouvert. L’AdBlue risque de cristalliser par temps froid.

Processus de reprogrammation pour défaut AdBlue sur pelle Doosan DX300 (EDC17CV41)

Pour supprimer durablement les défauts liés à l’AdBlue sur une pelle Doosan DX300 équipée du moteur DL08P, une intervention directe sur le calculateur Bosch EDC17CV41 s’impose. Cette opération vise à désactiver proprement les fonctions SCR responsables des codes erreurs récurrents et des pertes de puissance.

1. Diagnostic initial

L’intervention débute par une lecture complète des défauts enregistrés dans l’ECU via un outil compatible Bosch (bench ou diagnostic OBD, selon accès). Les codes liés à l’injection d’urée, au chauffage du module, à la pompe ou à la température SCR sont analysés. Le but est de confirmer une défaillance du système AdBlue et d’éviter un remplacement inutile de composants.

2. Lecture du fichier moteur

Le fichier moteur est extrait directement depuis le calculateur Bosch EDC17CV41 en mode bench, sans ouverture de l’ECU. Cette opération permet de récupérer une image complète au format .bin, incluant les cartographies moteur, la gestion des capteurs, les fonctions antipollution (SCR, EGR), ainsi que les routines de diagnostic et de sécurité. Ce fichier constitue la base sur laquelle seront appliquées les modifications nécessaires à la désactivation du système AdBlue.

3. Analyse des fonctions antipollution

Les blocs liés à la gestion du SCR sont identifiés manuellement ou via script : injection AdBlue, surveillance capteurs NOx, pressions, températures, alimentation électrique, logique d’inducement. On localise également les adresses correspondant aux DTCs actifs liés au système.

4. Modification des données internes

Une fois le fichier moteur extrait, les fonctions AdBlue sont désactivées directement dans le calculateur Bosch EDC17CV41. Grâce à l’analyse des blocs internes (cartographies et logiques SCR), les valeurs liées à l’injection d’urée, aux capteurs NOx, aux stratégies de réduction de puissance et aux codes défauts sont neutralisées de manière ciblée.

Les maps concernées sont identifiées à l’aide de définitions précises issues de fichiers DAMOS/A2L. Toutes les fonctions du système SCR sont ainsi désactivées proprement pour éviter tout retour d’erreur via le réseau CAN ou les outils de diagnostic constructeur. Cette modification garantit une suppression stable et durable du système AdBlue sur la pelle Doosan DX300.

6. Réécriture du calculateur et validation sur machine

Après avoir modifié le fichier moteur, on le réinjecte directement dans le calculateur Bosch EDC17CV41, en mode bench, en utilisant le même protocole que pour la lecture initiale. Une fois le moteur redémarré, on enchaîne avec une série de tests pour valider la désactivation complète du système AdBlue.

On vérifie d’abord le démarrage à froid, puis à chaud, pour s’assurer que l’ECU reste stable dans toutes les conditions. Ensuite, on analyse les paramètres PID liés à l’AdBlue : ils restent inactifs, ce qui confirme que le système SCR ne fonctionne plus. On contrôle également l’absence de mode dégradé et on s’assure que le calculateur ne réduit plus la puissance.

Pour finir, on pousse la machine en pleine charge. On vérifie que le moteur délivre toute sa puissance, sans défaut, et que la pelle fonctionne normalement sans injection d’urée. Cette reprogrammation garantit un fonctionnement fluide, fiable, et sans retour de problème lié au système antipollution.

En savoir plus sur Doosan et les désactivations d’émissions

Consultez notre section dédiée à la gamme Doosan pour découvrir toutes nos solutions de suppression AdBlue, DPF et EGR, compatibles avec de nombreux modèles de pelles, chargeuses et autres machines du BTP.

👉 Voir tous les articles Doosan