Désactivation FAP sur Matrot 4300 : Reprogrammation du boîtier EDC17 CV52 sur moteur Deutz TCD 6.1

La désactivation des systèmes FAP (Filtre à Particules Diesel) et EGR (Exhaust Gas Recirculation) est une solution efficace pour éliminer les contraintes de régénération et les problèmes récurrents liés à l’encrassement des filtres et vannes. Dans cet article, nous détaillons une intervention technique réalisée sur un pulvérisateur Matrot 4300, équipé d’un moteur Deutz TCD 6.1 et géré par un boîtier EDC17 CV52.

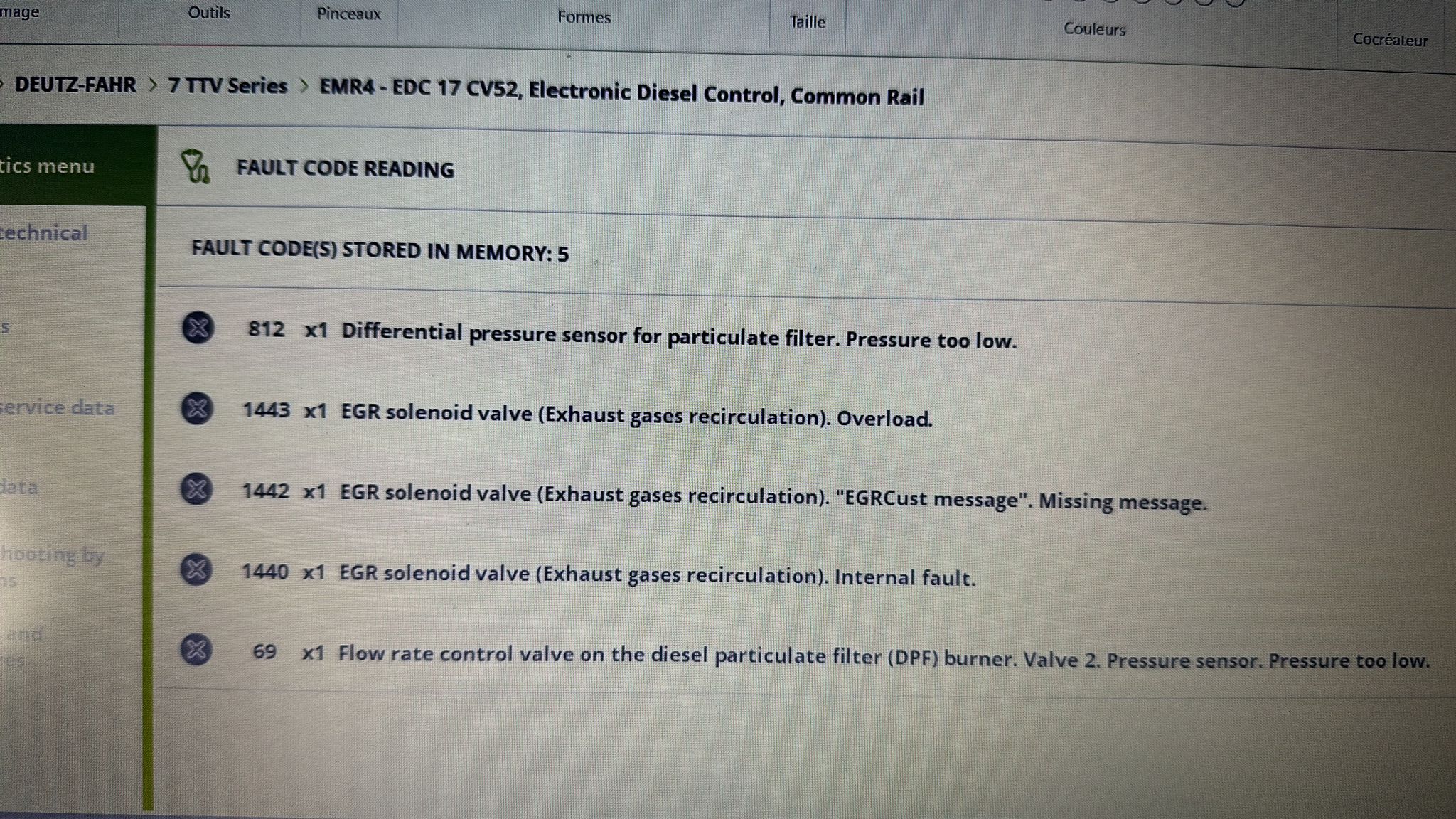

Analyse des défauts relevés sur le pulvérisateur Matrot 4300

Avant notre intervention, plusieurs défauts impactaient la performance de la machine en raison du dysfonctionnement des systèmes SCR, FAP et EGR. Notamment, le tableau de bord affichait le code SPN 524030, souvent associé à une surcharge de suie dans le FAP, ce qui entrave le bon déroulement des régénérations. En plus de ce code, nous avons également relevé d’autres anomalies techniques telles que le code 812, indiquant une pression trop basse détectée par le capteur de pression différentielle du filtre à particules. Cela signifiait une difficulté à détecter correctement l’encrassement du filtre, empêchant ainsi une régénération adéquate.

D’autres défauts concernaient la vanne EGR, notamment le code 1443, qui signalait une surcharge, ainsi que le code 1442, lié à une erreur de communication avec la vanne. Par ailleurs, le code 1440 faisait référence à un défaut interne de la vanne EGR, la bloquant en position ouverte ou fermée, perturbant ainsi le flux des gaz d’échappement. Enfin, le code 69 indiquait une défaillance au niveau de la valve de contrôle du DPF, à cause d’un capteur de pression défectueux. Ces différents codes révélaient une accumulation excessive de suie dans le FAP et une panne de la vanne EGR, entraînant une limitation de puissance et l’activation du mode dégradé.

Reprogrammation du boîtier EDC17 CV52 : Désactivation des systèmes FAP et EGR

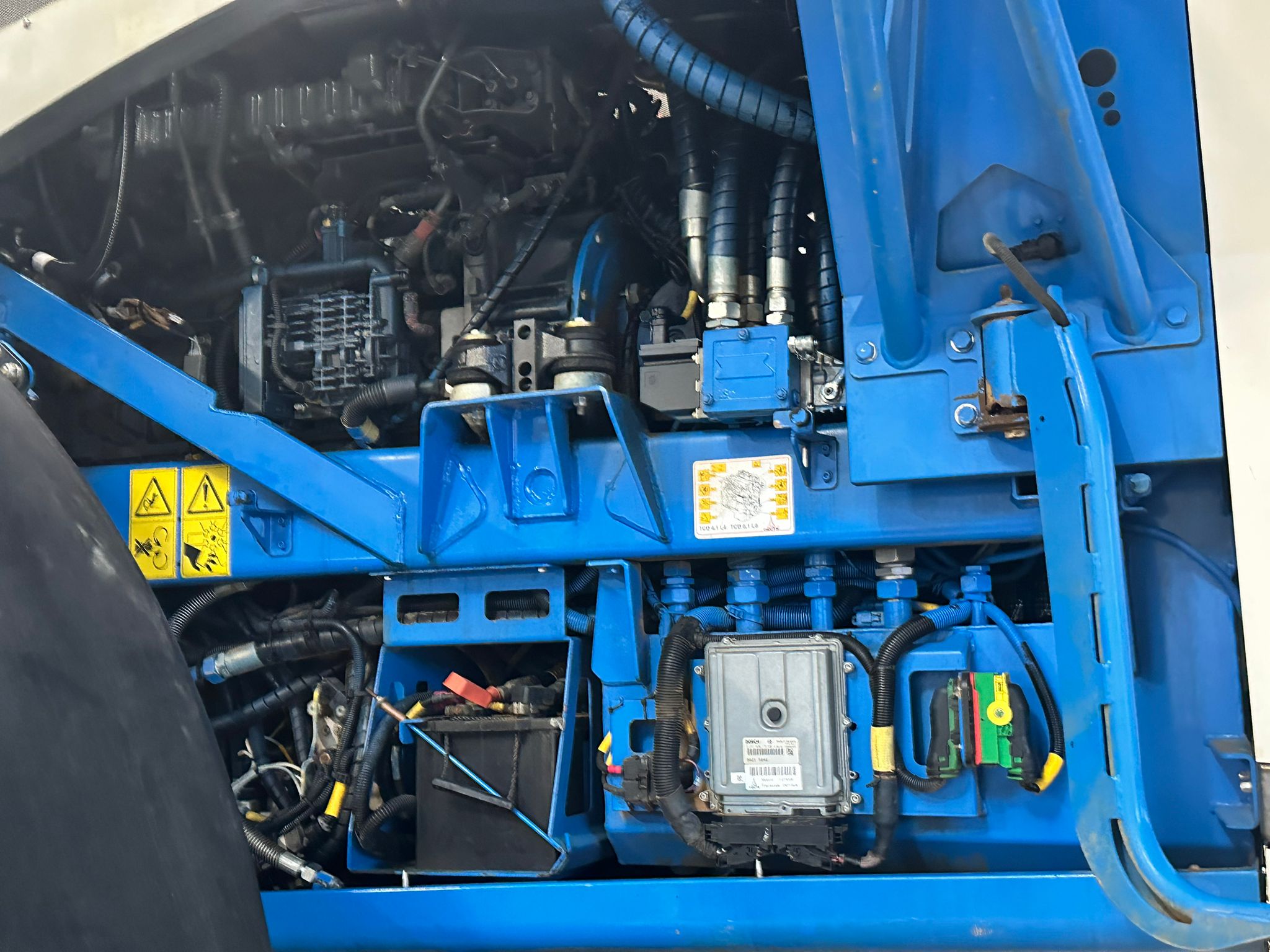

L’intervention réalisée sur le boîtier EDC17 CV52 a permis de désactiver les systèmes FAP et EGR, tout en restaurant la pleine capacité du moteur Deutz TCD 6.1. L’une des premières étapes a consisté à inhiber le processus de régénération du FAP. Nous avons modifié le programme du boîtier pour désactiver cette fonction, ce qui a empêché le moteur de forcer la régénération. Cela a non seulement évité les arrêts intempestifs de la machine, mais a également réduit la surconsommation de carburant causée par des régénérations trop fréquentes.

Nous avons également déconnecté physiquement les capteurs de pression différentielle du FAP, ainsi que les sondes de température des gaz d’échappement. Ces capteurs étaient responsables des erreurs fréquentes rencontrées avant l’intervention. Leur suppression a permis d’éliminer définitivement ces défauts et d’assurer un fonctionnement stable sur le long terme.

Concernant la vanne EGR, nous avons procédé à une neutralisation complète, à la fois au niveau logiciel et matériel. Ce blocage de la vanne EGR a permis de maintenir un flux d’air propre et stable dans le moteur, améliorant ainsi l’efficacité de la combustion tout en réduisant les dépôts de suie dans le circuit d’échappement.

Enfin, la reprogrammation a également supprimé les limitations de puissance imposées par le FAP et l’EGR. Cela a permis de restaurer le plein potentiel du moteur en termes de couple et de puissance. L’élimination du mode dégradé a également contribué à rétablir les performances globales du pulvérisateur.

Avantages de la solution de désactivation FAP/EGR sur Matrot 4300

Grâce à cette intervention, le pulvérisateur Matrot 4300 a retrouvé une performance optimale, sans les contraintes des systèmes FAP et EGR. Le moteur Deutz TCD 6.1 fonctionne désormais à pleine puissance, avec un couple optimisé pour les travaux intensifs. Les erreurs fréquentes liées aux capteurs FAP et à la vanne EGR ont été supprimées, améliorant ainsi la fiabilité de la machine et réduisant les interventions d’entretien.

En supprimant le processus de régénération forcée, nous avons également réduit les besoins d’entretien tout en prolongeant la durée de vie des composants du moteur. Sans régénérations fréquentes, le moteur consomme moins de carburant, ce qui se traduit par une réduction des coûts d’exploitation du pulvérisateur.

Pour plus d’informations sur les interventions sur les moteurs Deutz, vous pouvez consulter cet article. Nous proposons également des solutions spécifiques aux pulvérisateurs, disponibles ici.