Des codes et des défauts problème Adblue et FAP Komptech Crambo 5200

Elimination définitive Adblue et FAP sur Komptech Crambo 5200

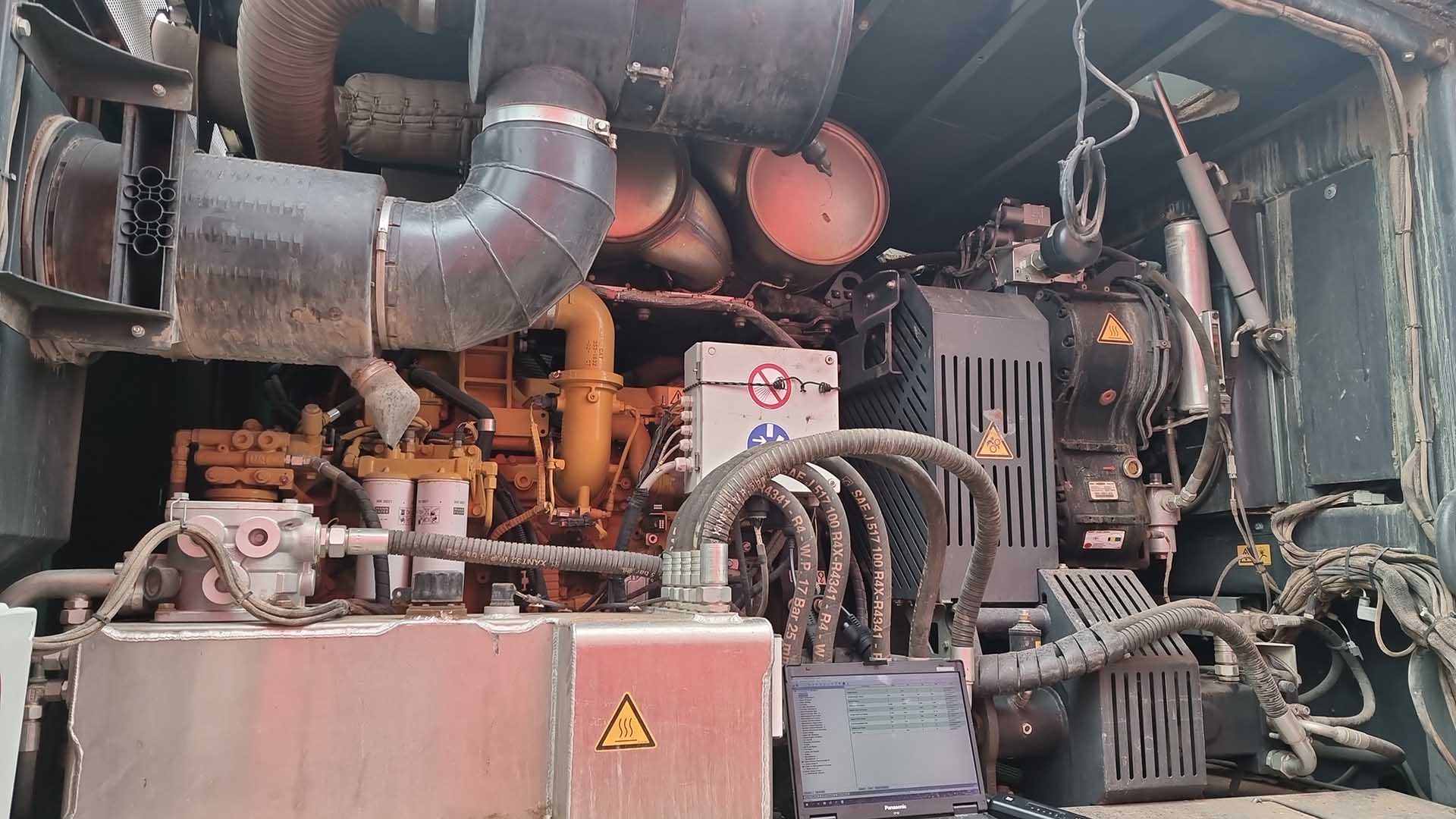

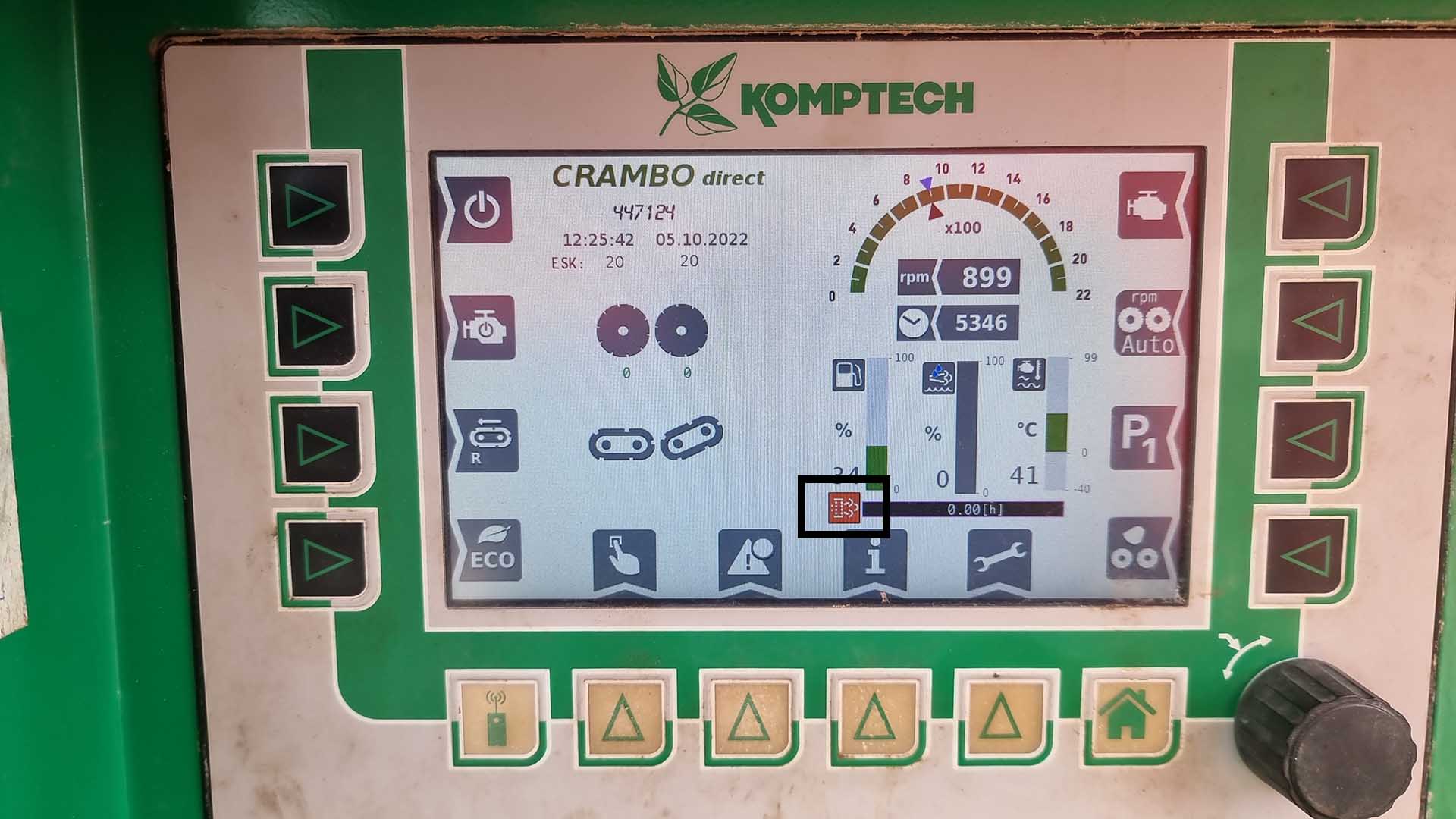

Si vous possédez un broyeur Komptech Crambo 5200 équipé du moteur C13 Caterpillar, vous pouvez rencontrer des problèmes. Principalement les soucis concernent le dispositif FAP (Filtre à particules) et Adblue (SCR). Nous vous donnons plus d’informations sur comment régler définitivement le soucis ainsi qu’une meilleure visibilité sur les codes défauts présents.

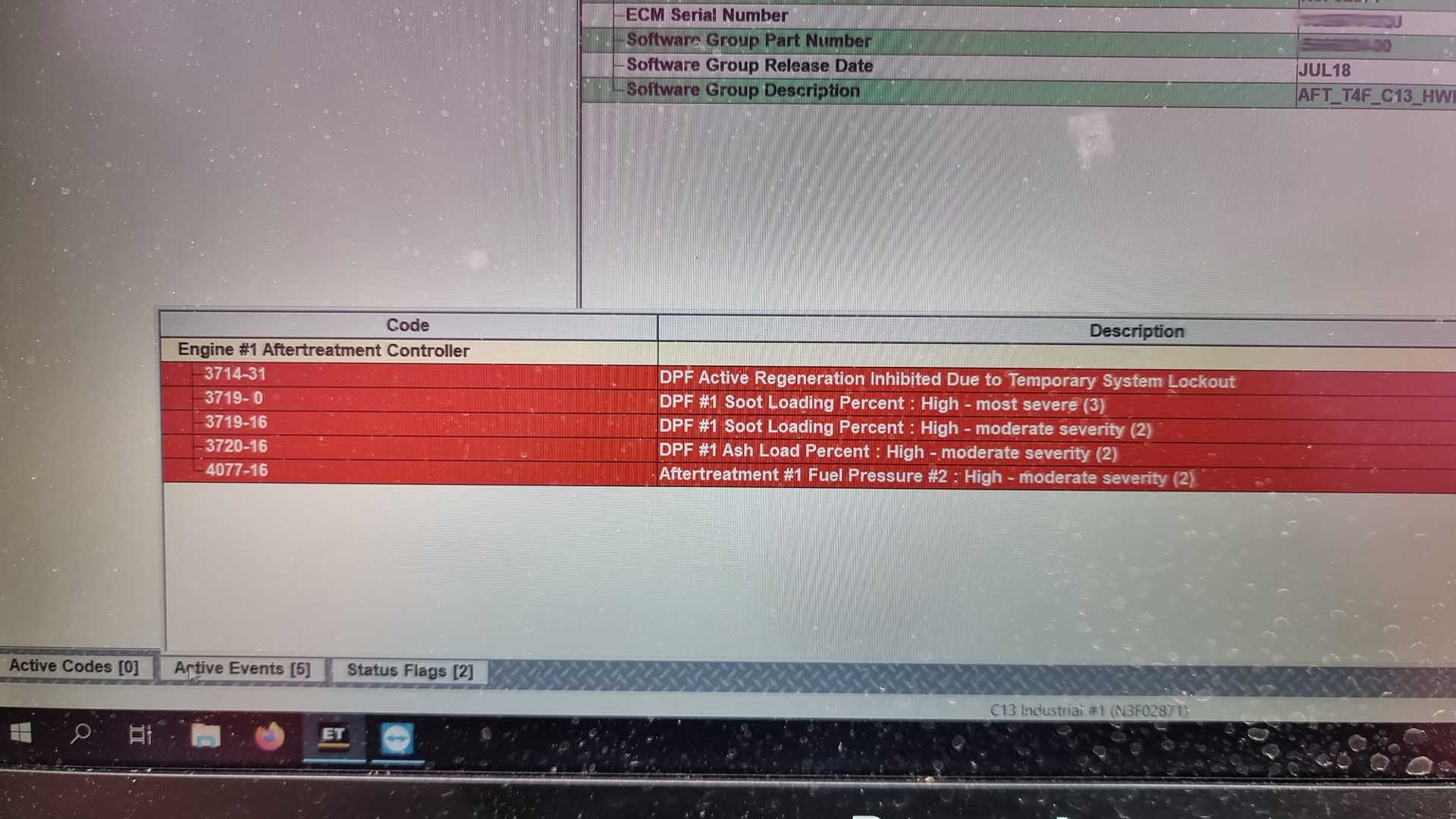

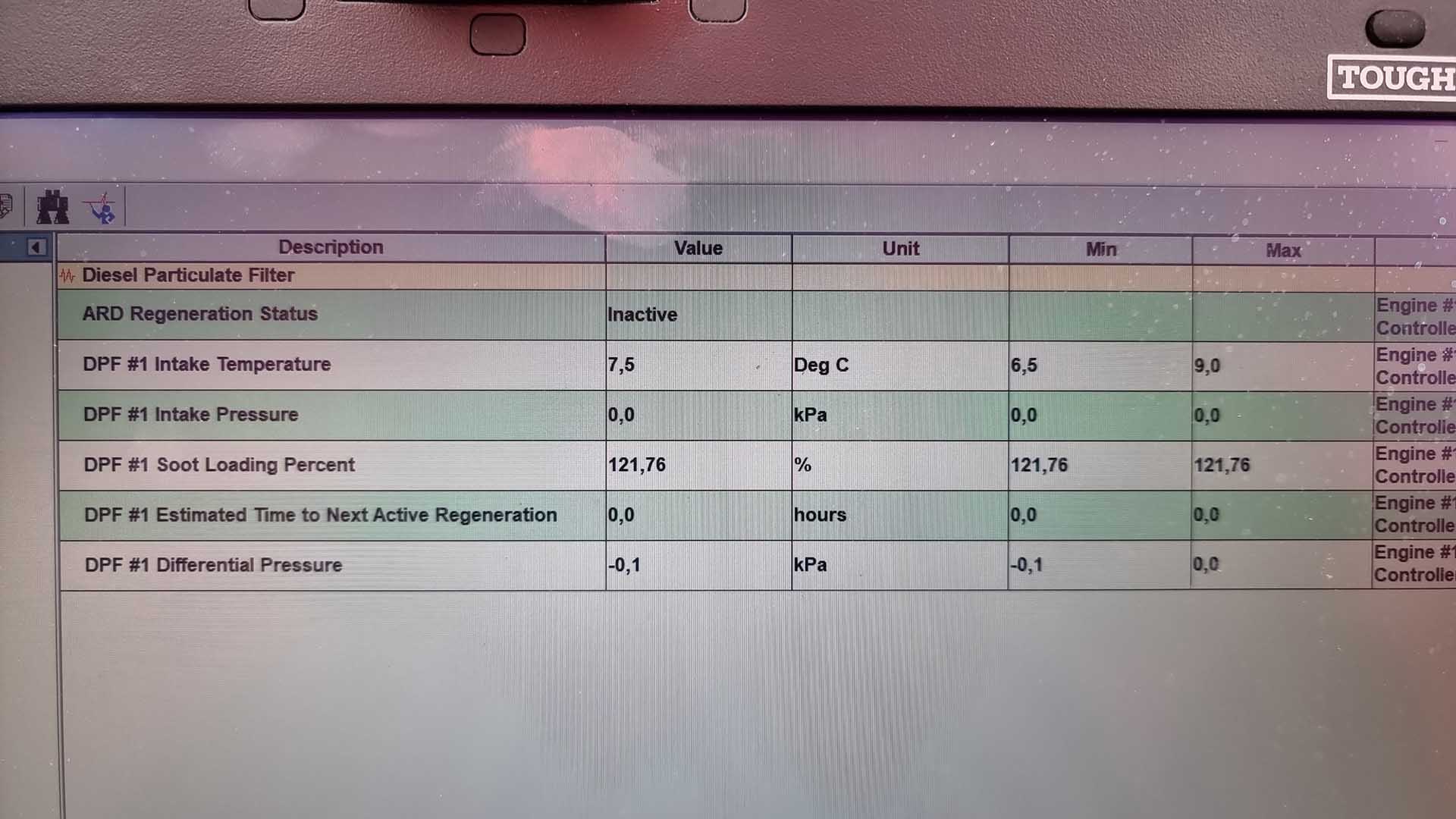

Les différents codes tels que le 3714-31 indique que la régénération est impossible due au verrouillage des paramètres de la machine. Les codes défauts suivants 3719-0 et 3719-16 on voit que le taux de suies présent dans le FAP est haut. Sous la norme Tier 4F (l’inducement severity level) en soit le niveau de sévérité comprend différents seuils. Ici le second seuil ‘moderate severity’ empêche déjà le fonctionnement de la machine dans les conditions optimales, puis le Severity de niveau 3 bloque toute probabilité de s’en sortir sans une intervention avancée ou couteuse. On aperçoit également que le taux de cendres est lui aussi trop élevé. En plus des défauts présents au niveau de la filtration des particules fines, nous avons un problème SCR (4077-16).

Comment s’en sortir avec tous ces codes ?

En soit il n’y a pas 2000 façons. Soit vous faites intervenir CAT qui va vous changer une bonne partie des éléments antipollution de la machine et vous soulager d’une bonne dizaine de milliers d’euros, soit vous prenez le taureau par les cornes et vous supprimez le système définitivement. La solution de supprimer le FAP et le système SCR est possible via nos logiciels, et programmes spécialement développés pour cette opération. Théoriquement cette opération est réservée lorsque les machines partent à l’export (légalement il est interdit en Europe d’outrepasser les dispositifs antipollution). C’est réservé pour l’Afrique ou le Moyen Orient.

La taux de succès de l’opération

Notre équipe d’ingénieurs est spécialisée dans la création de programmes sur mesure visant à ôter les systèmes antipollution de divers et variés équipements. L’opération est toujours un succès et surtout permet de diviser par 2 ou 3 la facture.

Supprimer le filtre à particules nécessite l’intervention physique de votre équipe de techniciens afin de le vider. La céramique doit être ôtée pour permettre aux gaz d’échappement de circuler librement. Dans notre cas, nous avions un taux de suies présent de l’ordre de 120%… ce qui est énorme et nécessite une intervention immédiate.

Plus de défaut après réalisation de l’opération

Les défauts concernant le système Adblue FAP et EGR sont désormais effacés, le mode LIMP (Inducement reduction) est désactivé et la machine retrouve donc la totalité de sa puissance.

Opérations possibles sur toute la gamme Caterpillar

Notre savoir faire permet d’intervenir sur la totalité des machines Cat, tous moteurs et calculateurs confondus. Vous pouvez retrouver le récapitulatif et la faisabilité des machines CAT sur notre page explicative ainsi que toutes nos opérations déjà réalisées ici.